Fitting incremental forming control system and method

A progressive forming and control method technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of complex system composition, large number of molds, large equipment volume, etc., and achieve the effect of simplifying the control system, reducing the volume, and simplifying the production operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

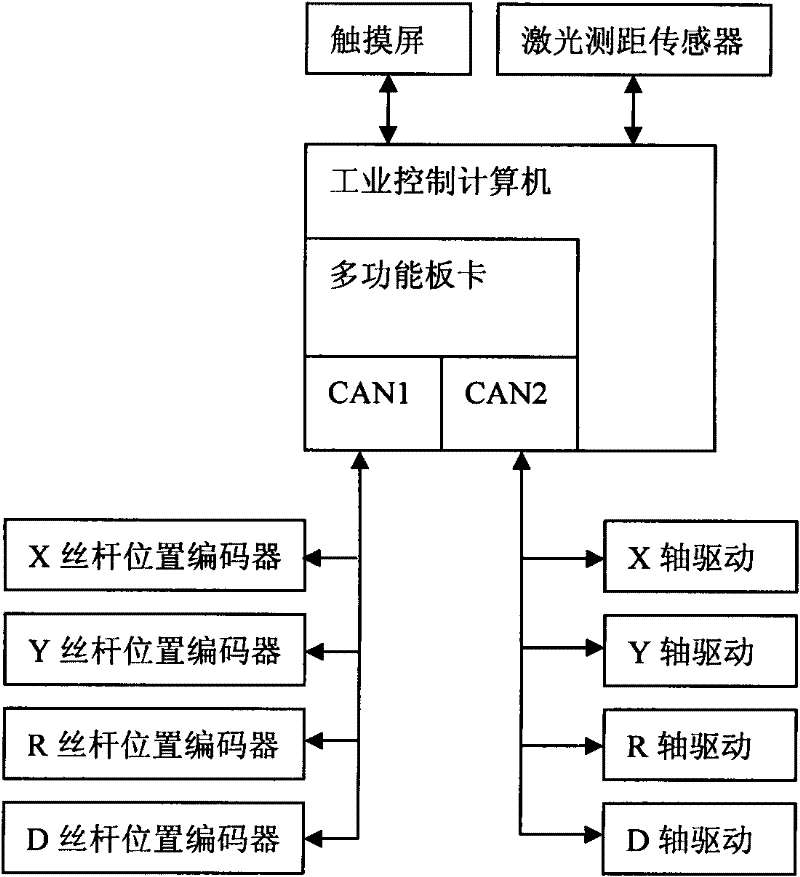

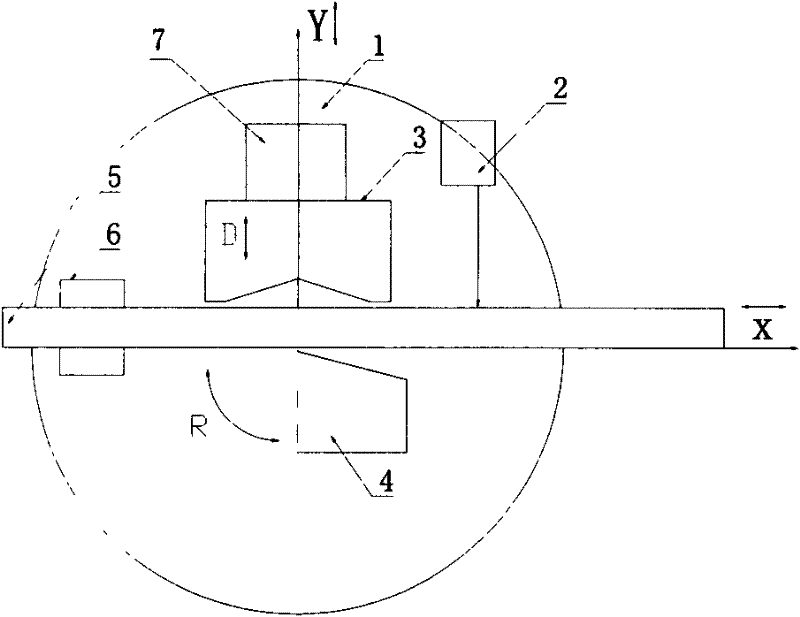

[0016] combine figure 1 , the present invention's fitting incremental forming control system includes a touch screen, a laser ranging sensor, an industrial control computer, a multi-function card, an X screw position encoder, a Y screw position encoder, an R screw position encoder, and a D screw position encoder. Position encoder, X-axis drive, Y-axis drive, R-axis drive, D-axis drive, the touch screen, industrial control computer, X-axis drive, Y-axis drive, R-axis drive, D-axis drive are installed in the control cabinet, The multi-function card includes CAN1 and CAN2 bus interfaces, and is installed in the slot of the industrial control computer. The X screw position encoder, Y screw position encoder, R screw position encoder, and D screw position encoder are respectively installed in the The tails of the X screw rod, Y screw rod, R screw rod, and D screw rod, the laser distance sensor 2, and the touch screen are respectively connected to the industrial control computer thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com