Quick vehicle-type reacting furnace

A fast-response, furnace-body technology, applied in furnaces, furnace types, lighting and heating equipment, etc., to achieve the effects of low investment, convenient and flexible adjustment, and short parameter change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

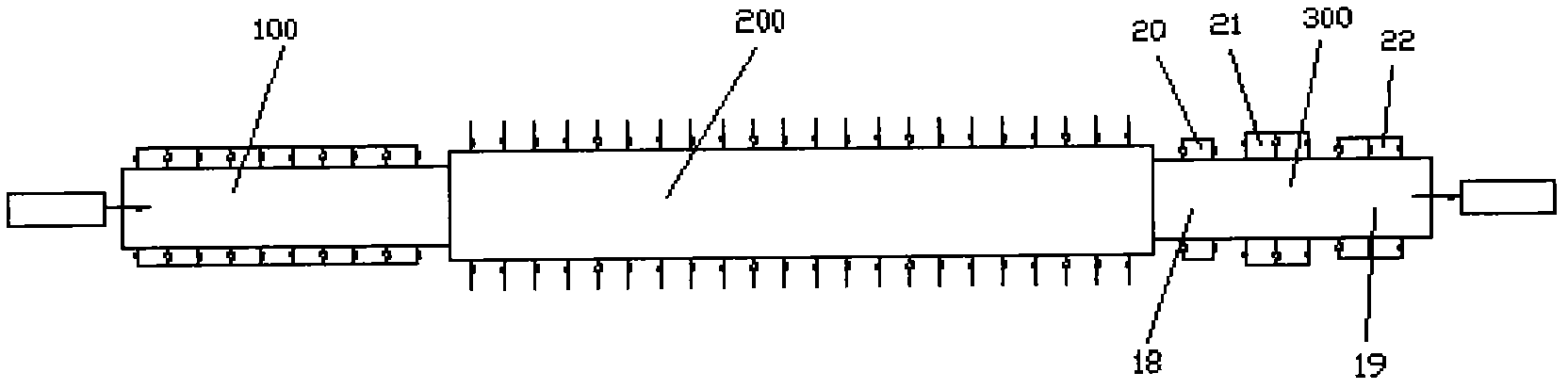

[0043] Such as figure 1 As shown, the car-type rapid reaction furnace is composed of furnace body, furnace car and cooling system under the car; 300; the preheating section is provided with a smoke exhaust system, the combustion section is provided with a combustion system, and the cooling section is provided with a cooling system.

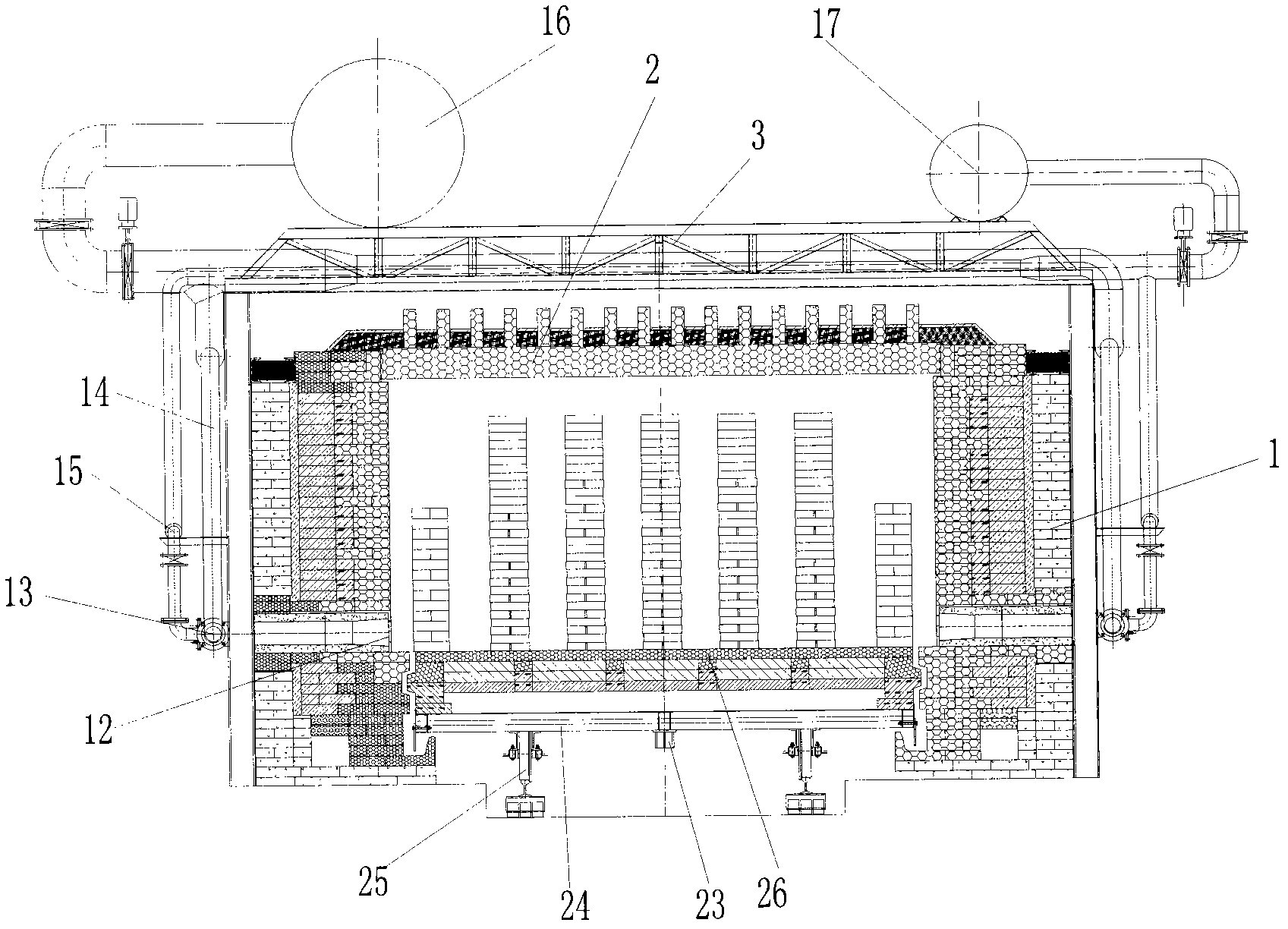

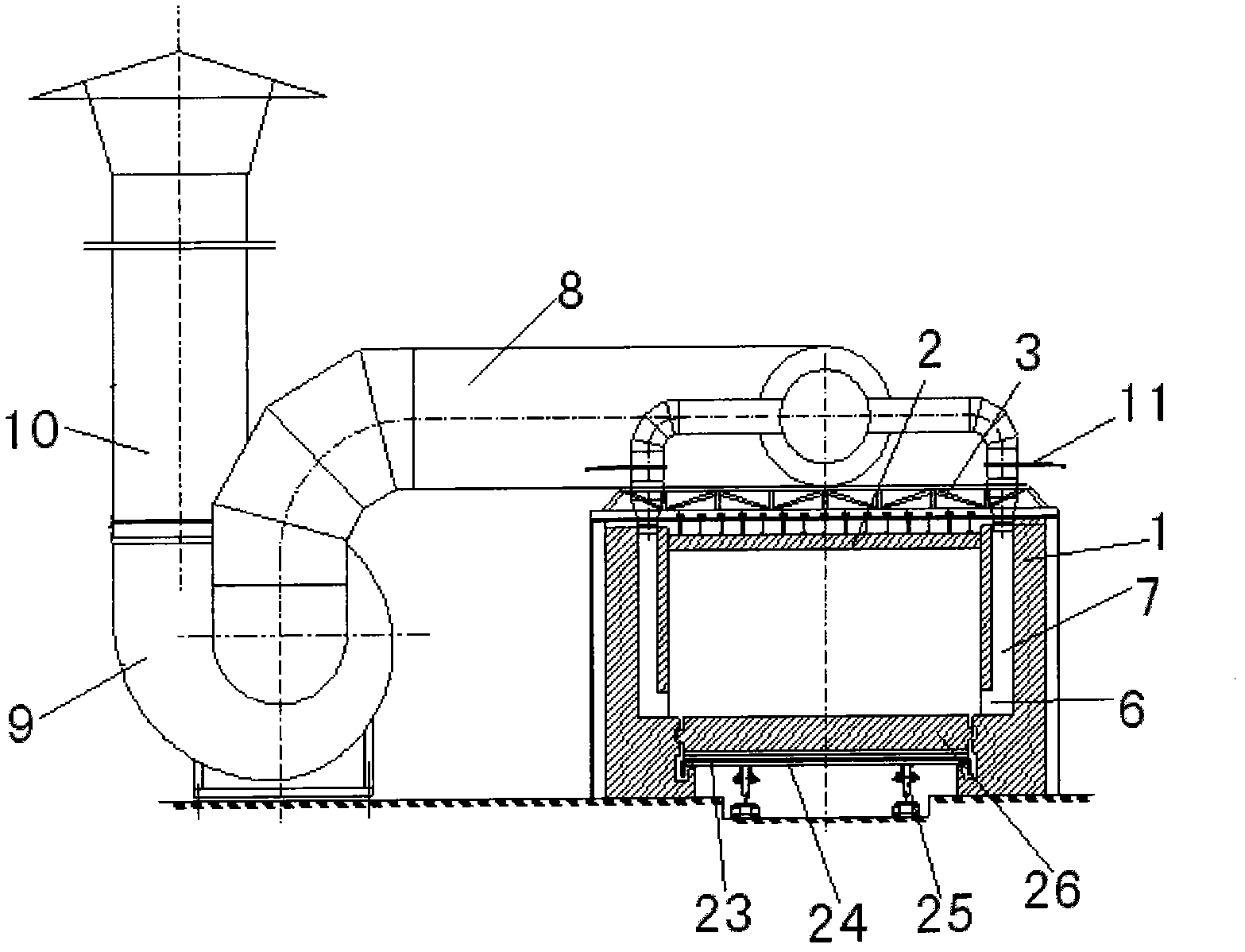

[0044] Such as figure 2 and image 3 As shown, the body of the car-type rapid reaction furnace of the present invention is composed of a furnace wall 1 and a furnace roof 2 . In order to reinforce the furnace body, a steel frame structure 3 is provided in the furnace body.

[0045] The function of the furnace wall is:

[0046] a. Together with the furnace roof and furnace car lining bricks, it forms the furnace path. The temperature in the furnace, especially the combustion section, is very high, so the furnace wall must withstand high temperature for a long time;

[0047] b. The temperature difference between the inside and outside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com