Sink-type top inflow sand flushing gallery structure

A corridor and sand flushing technology, which is applied in water conservancy projects, hydropower stations, traditional hydroelectric energy, etc., can solve problems that endanger the structural safety of sand flushing tunnels, prevent cavitation damage, ensure safety, and reduce project investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

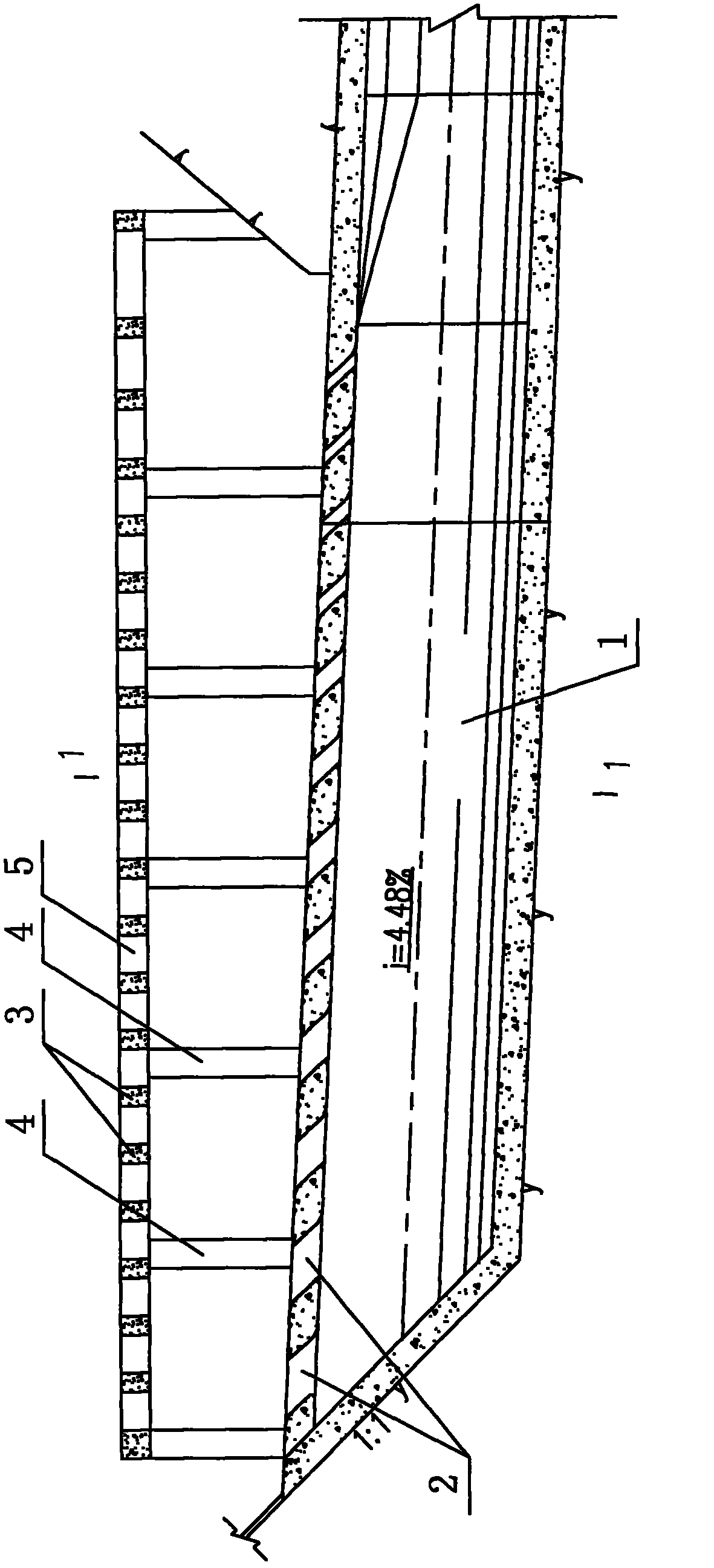

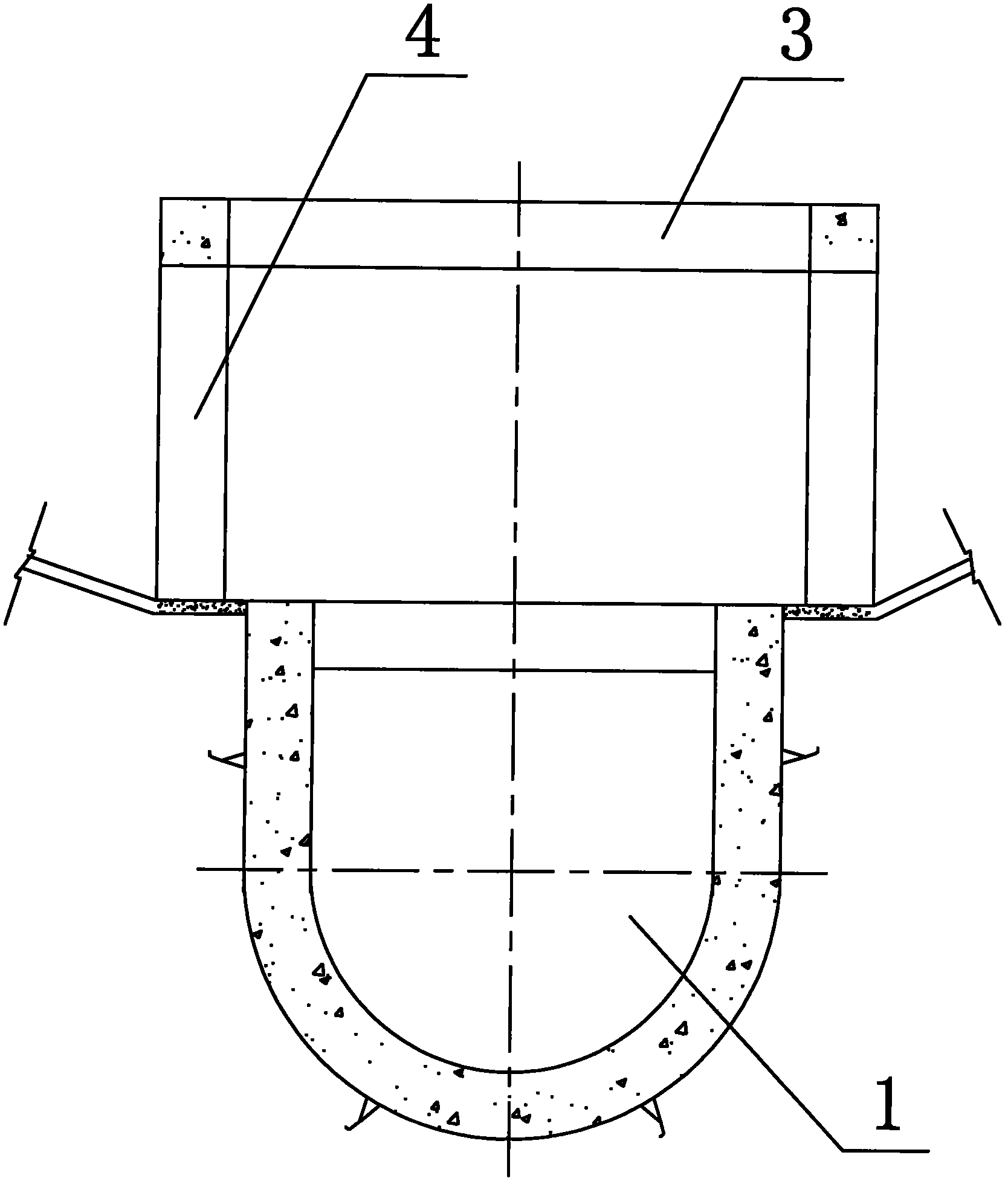

[0015] For hydropower stations built on silt-rich rivers, in order to prevent large particles of silt from entering the turbines of the power station, a desilting basin is usually built before the water inlet. Such as Figure 1-Figure 4 As shown, this embodiment includes a corridor main body 1 (made of C50 anti-scouring and wear-resistant concrete) located at the front of the sand washing tunnel and integrally arranged in the rock body at the bottom of the grit chamber. The angle is generally controlled at 70-90°, keeping a certain distance from the front edge of the water inlet (in order to simplify the structure, the sand flushing corridor should be as far away from the water inlet as possible, but the water inlet should be within the range of the sand flushing funnel), and the water flow outlet It is connected with the entrance of the flushing cave. The cross-section of the corridor main body 1 is in the shape of an inverted city gate with a round top and bottom; a group o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com