Floating drilling platform and construction technology used for bridge pier construction in water

A drilling platform and construction technology technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as inability to meet construction requirements and geographical restrictions, and achieve flexible assembly methods, reasonable structural design, and inability to solve problems. effect of beating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

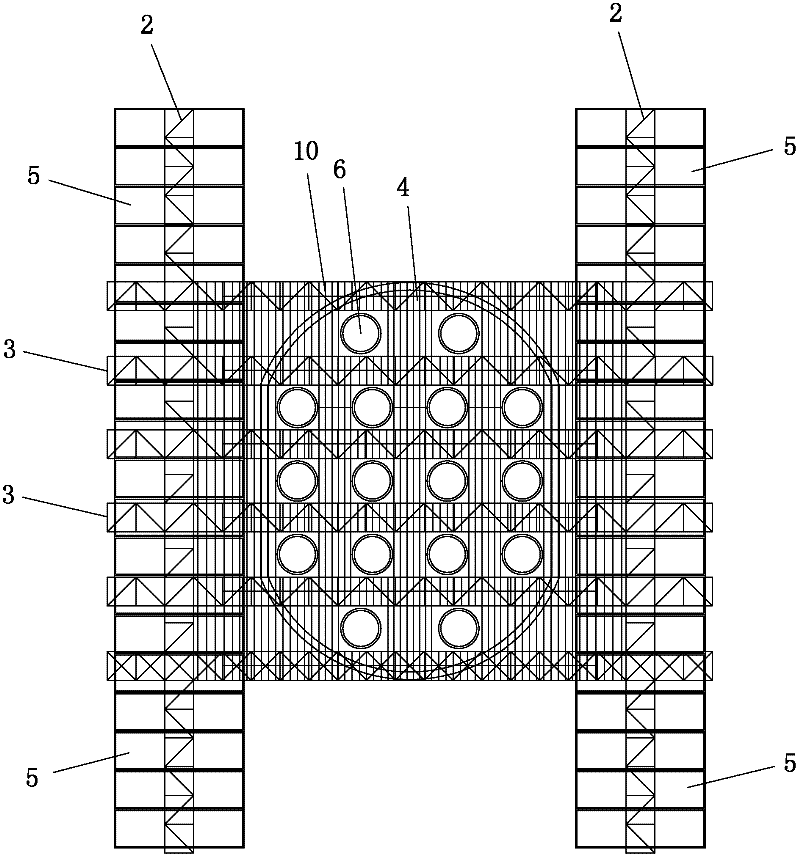

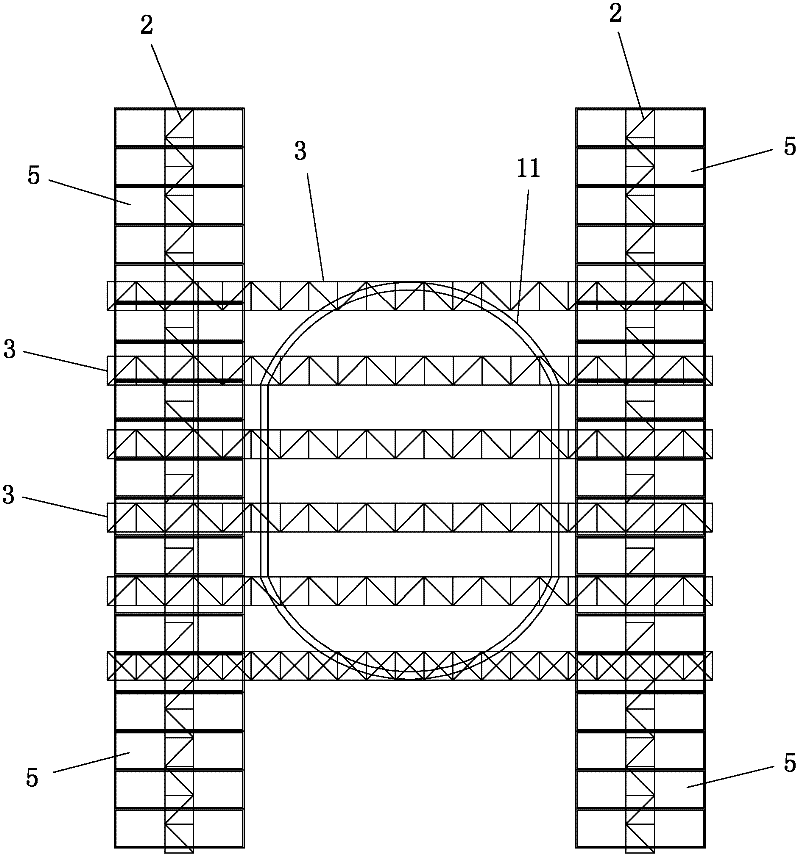

[0054] Such as figure 1 , figure 2 , image 3 and Figure 4 The shown floating drilling platform for bridge pier construction in water includes a floating supporting platform, a plurality of temporary fixing devices for temporarily fixing the floating supporting platform, and arranging on the floating supporting platform and drilling holes for construction. A hoisting system in which steel casings are used for hoisting piles, a plurality of temporary fixing devices are arranged around the surrounding sides of the floating support platform, and anchor cables 1 are passed between each temporary fixing device and the floating support platform. Make a tight connection. The floating support platform includes a horizontal floating body, a horizontal support frame fixedly installed on the horizontal floating body and a horizontal steel plate 4 paved on the horizontal supporting frame, and the horizontal floating body is composed of a plurality of small floating tanks 5 assembled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com