Single-screw extruder

A single-screw extruder and screw technology, which is applied in the field of extrusion equipment, can solve the problems that the gap is not easy to completely eliminate, affect the smoothness of the screw, and affect the quality of the injection molded parts, so as to facilitate the continuous travel, reduce the gap, and improve the mixing adequacy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

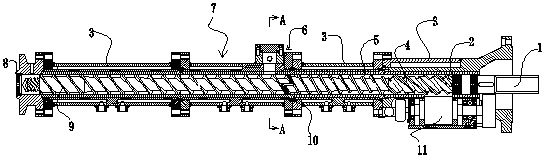

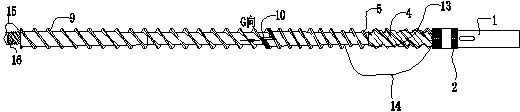

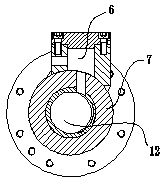

[0023] Below by specific embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further in detail:

[0024] The structure of the single-screw extruder of the present invention includes a housing 7 and a screw 1. The housing 7 has a rotary cavity 12, and the screw 1 is arranged in the rotary cavity 12. The casing 7 is composed of a plurality of hollow coupling bodies 3 connected together, and a connecting flange is provided between two adjacent coupling bodies 3 to facilitate their fixed connection.

[0025] The screw 1 has a feeding part 14 and a discharging part 15, and the housing 7 is provided with a feeding port and a feeding port. The feeding part 14 on the screw 1 is located at the feeding port of the housing 7. On the screw 1 The discharge part 15 of the casing 7 is plugged into the discharge port of the casing 7, and a collection box 11 is arranged below the discharge port of the casing 7.

[0026] A main push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com