Assembly welding process for propeller shaft bracket

A stern shaft frame and assembly and welding technology, which is applied in the field of ships, can solve the problems of affecting the service life of the ship, the process is not in place, and the accuracy of the stern shaft frame assembly and welding is poor, so as to avoid pyrotechnic correction, broad market space, and small position deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

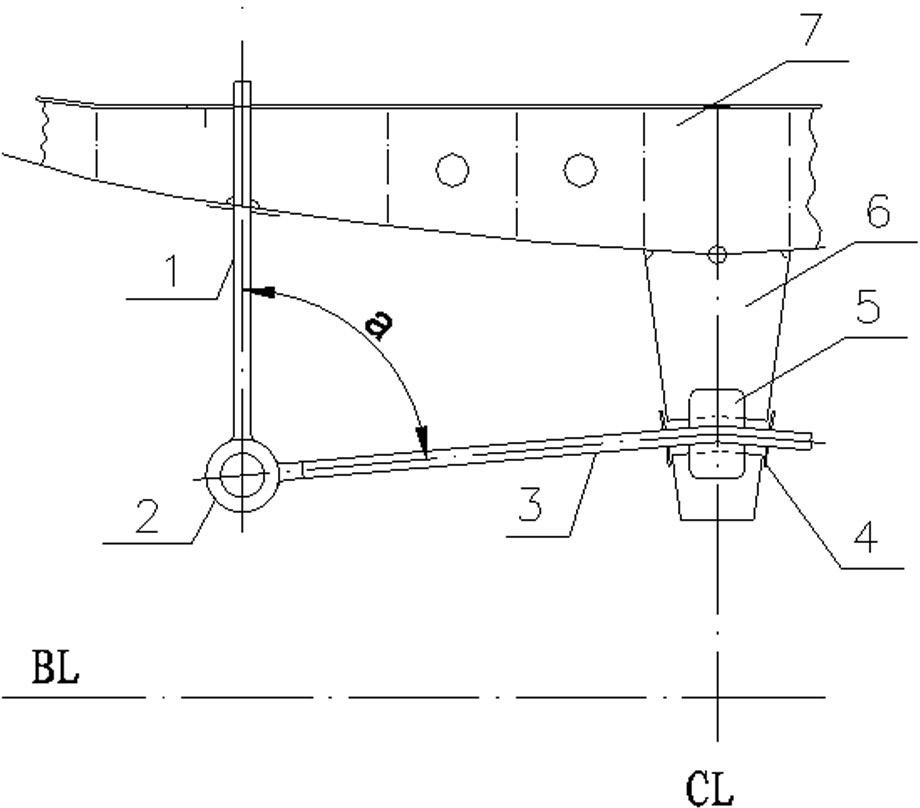

[0023] Below in conjunction with accompanying drawing, take kiloton class boat crossing 10 as embodiment to illustrate.

[0024] A stern shaft frame assembly and welding process comprises the following process steps:

[0025] A. The width of the stern shaft hub 2 is selected as 750mm, and a 0.2Mpa water pressure test should be done before assembly. Then align the deflection angles of the two supports according to the figure, and then calibrate the axes and apertures of the front and rear end surfaces of the stern hub 2, and then make temporary marks on each of four points on the left, right, up, and down.

[0026] B. According to the figure, take the center line CL as the center line, and BL as the horizontal line. Arrange the welding of the stern shaft frame at the bottom of the hull 7. The left and right sides are symmetrical. Measure the bottom plate of the hull and install the support arm 1 and cross arm 3 on the rib plate 6. position, and cut out corresponding position h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com