Enamelled flat wire online detection system

A technology of enamelled flat wire and detection system, which is applied in the field of enamelled flat wire, can solve problems such as low assessment, difficult surface quality, and high requirements for employees, and achieve the effect of ensuring surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

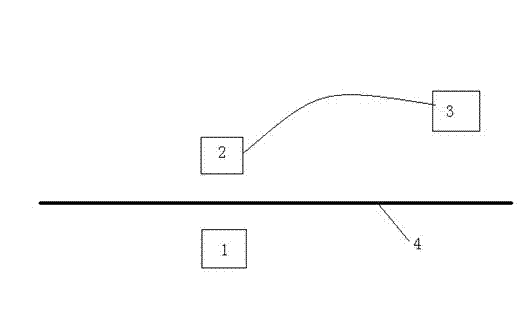

[0012] An enamelled flat wire online detection system according to the present invention, see figure 1 , the detection system includes an electromagnetic signal transmitting end 1 , an electromagnetic signal receiving end 2 and a processing device 3 . The electromagnetic signal receiving end 2 is adapted to the electromagnetic signal transmitting end 1 , and the electromagnetic signal receiving end 2 and the electromagnetic signal transmitting end 1 are respectively arranged on both sides of the enamelled flat wire 4 . The electromagnetic signal receiving end 2 is connected with the processing device 3; the processing device 3 processes the received electromagnetic signal according to the internally set surface quality control parameters, and displays and records the processing results in real time.

[0013] The invention is on-line detection, which can immediately reflect the surface quality problems of the enamelled flat wire, and is convenient for adjusting the process and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com