Lifting system for construction

A formwork technology for construction, which is applied in construction, building structure, and on-site preparation of building components. It can solve problems such as troublesome operation, danger of falling, and waste of time, so as to save the space occupied by equipment, speed up the construction progress, The effect of ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

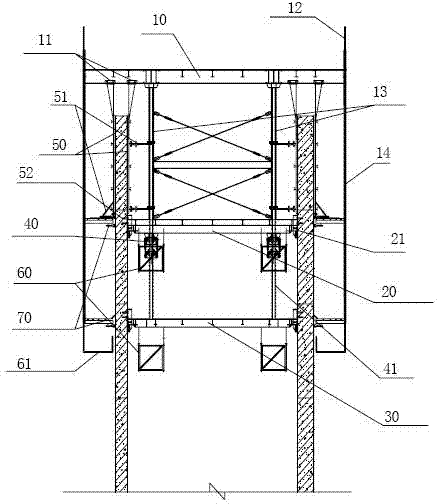

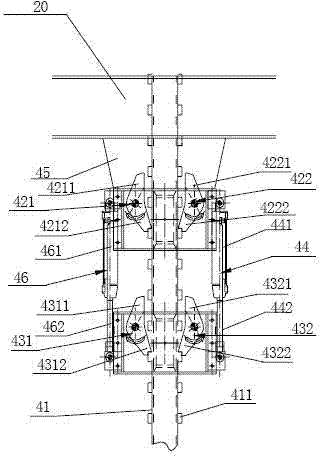

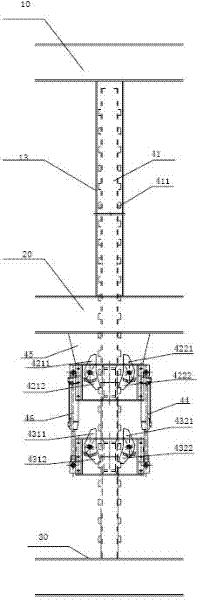

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 — Figure 8 B, shows the formwork lifting system for construction of an embodiment in detail.

[0032] Such as figure 1As shown, the construction formwork system includes a top platform 10 , a middle platform 20 and a bottom platform 30 arranged in sequence from top to bottom and parallel to each other. A track (not shown) perpendicular to the direction of the wall is provided at the bottom of the top platform 10, a pulley 11 is arranged on the track, and a wall formwork 50 is hung under the pulley, so that the wall formwork 50 can be horizontally along the top platform 10 Move, so as to facilitate mold opening and mold closing, of course, in other embodiments of the present invention, other methods in the prior art that can realize the horizontal movement of the wall formwork 50 can also be used. Between the top platform 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com