Luminous concrete brick produced from slag of construction waste and domestic waste

A technology for domestic waste and construction waste, applied in the field of concrete bricks, can solve problems such as difficulty in meeting practical requirements, insufficient endurance of concrete bricks, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

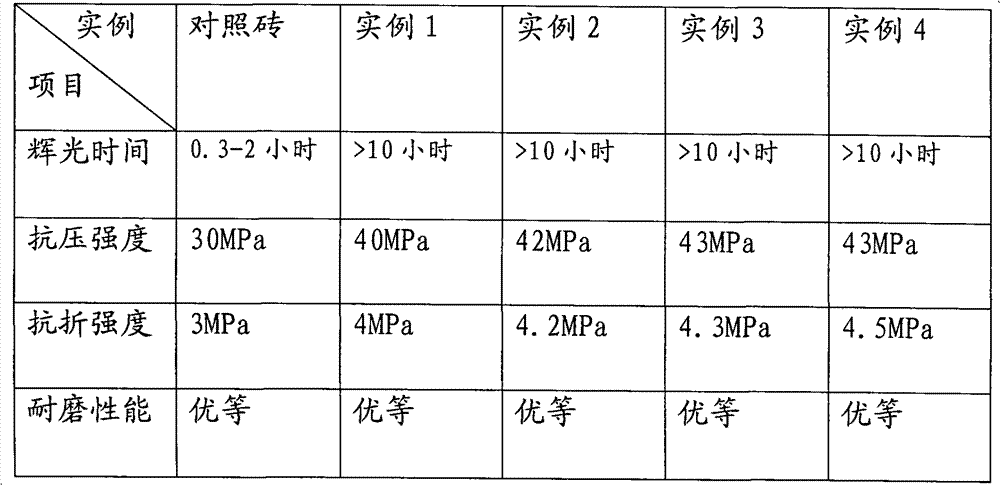

Examples

Embodiment 1

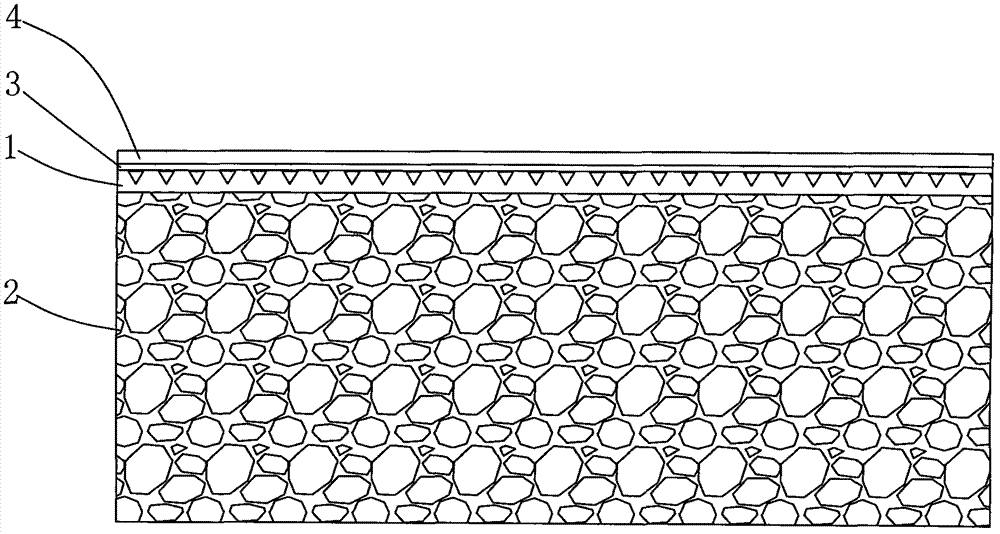

[0034] see figure 1 , a luminous concrete brick made of slag from construction waste and domestic waste, consisting of a surface layer 1 and a base layer 2, the base layer 2 and surface layer 1 have the above-mentioned material components, and cement products are conventionally produced The base layer 2 and the surface layer 1 are prepared and solidified; then at least part of the surface of the surface layer 1 is painted with a luminescent layer 3 containing luminous or fluorescent substances, and the composition of the luminescent layer 3 is 10% carbonic acid Strontium luminous or fluorescent substances, at last, paint protective film 4 on the luminescent layer, described protective film 4 comprises the following components by weight percentage, colloidal silicon dioxide 10kg, siloxane 12kg, polyether 13kg, organic The film-forming agent is 3kg, and the balance is water, which can be used as a liquid.

Embodiment 2

[0036] see figure 1 , a luminous concrete brick made of slag from construction waste and domestic waste, consisting of a surface layer 1 and a base layer 2, the base layer 2 and surface layer 1 have the above-mentioned material components, and cement products are conventionally produced The base layer 2 and the surface layer 1 are prepared and solidified; then at least a part of the surface of the surface layer 1 is painted with a luminescent layer 3 containing luminous or fluorescent substances, and the composition of the luminescent layer 3 is 13% carbonic acid Strontium luminous or fluorescent substances, finally, on the luminescent layer 3, paint a protective film 4, the protective film 4 includes the following components by weight percentage, colloidal silicon dioxide 9kg, siloxane 13kg, polyether 15kg, Organic film-forming agent 3kg, the balance is water, it can be used as a liquid.

Embodiment 3

[0038] see figure 1 , a luminous concrete brick made of slag from construction waste and domestic waste, consisting of a surface layer 1 and a base layer 2, the base layer 2 and surface layer 1 have the above-mentioned material components, and cement products are conventionally produced The base layer 2 and the surface layer 1 are prepared and solidified; then at least part of the surface of the surface layer 1 is painted with a luminescent layer 3 containing luminous or fluorescent substances, and the composition of the luminescent layer 3 is 15% carbonic acid Strontium luminous or fluorescent substances, at last, paint protective film 4 on the luminescent layer, the protective film 4 includes the following components by weight percentage, colloidal silicon dioxide 11kg, siloxane 11kg, polyether 12kg, organic The film-forming agent is 4kg, and the balance is water, which can be used as a liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com