Screw washer assembly machine

A combination machine and gasket technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low work efficiency, achieve the effect of saving labor and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

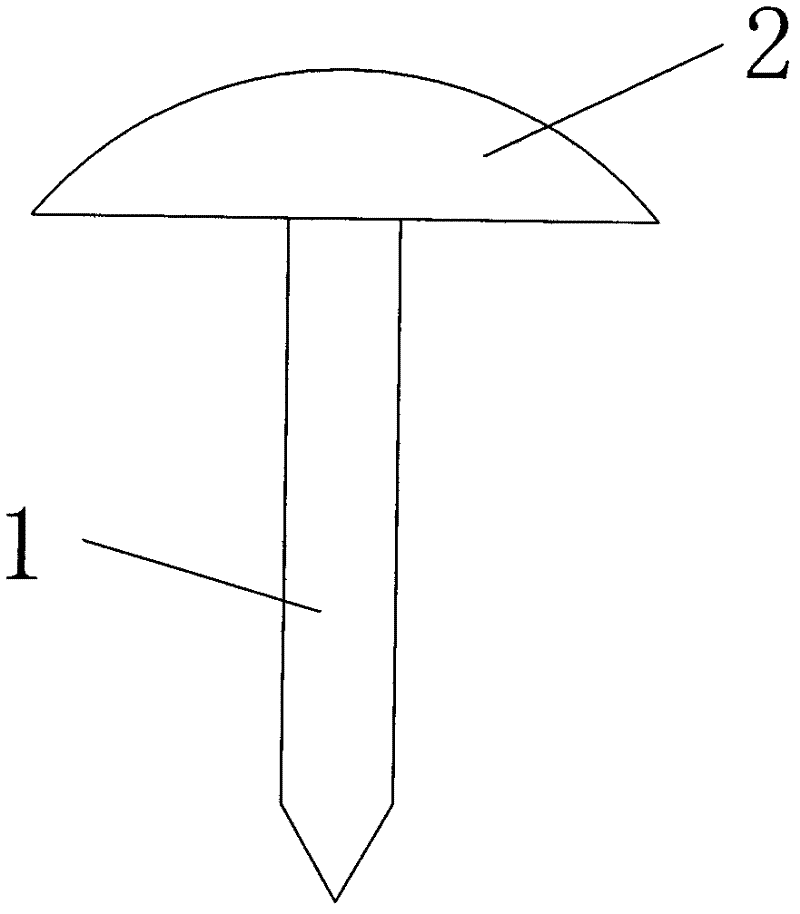

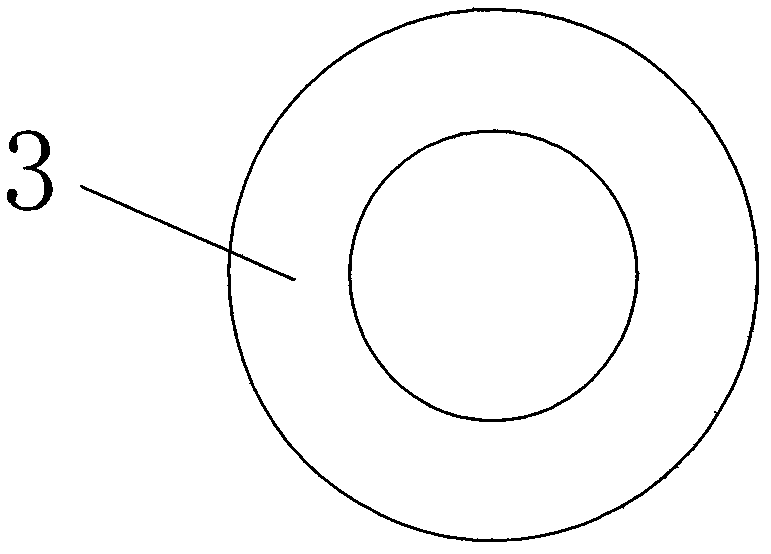

[0028] Reference figure 2 , image 3 , The screw includes a screw part 1 and a tail part 2, and the washer 3 is a ring with a central hole.

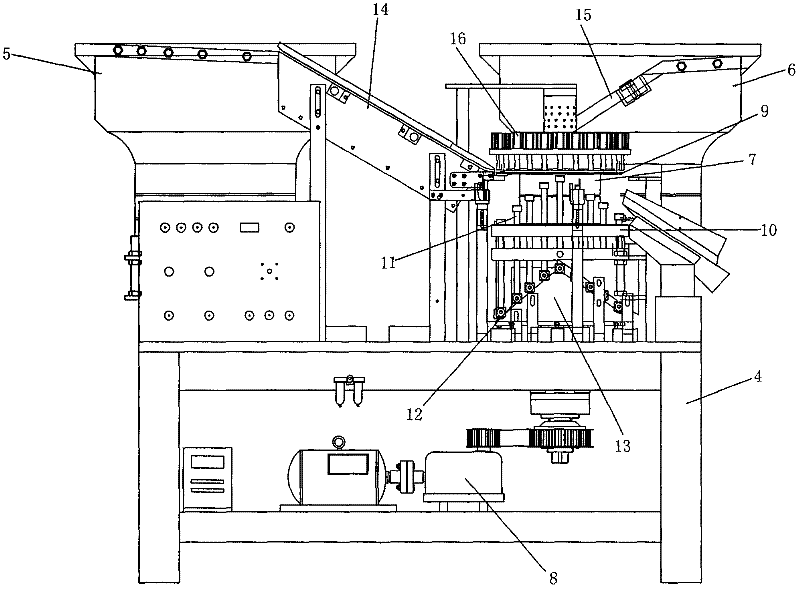

[0029] Reference figure 1 , A screw washer assembly machine, including a frame 4, the frame 4 has a working platform, the working platform is provided with a screw vibration plate 5 and a washer vibration plate 6, the screw vibration plate 5 is provided with There is a spirally rising screw ascending track, and the washer vibration plate 6 is provided with a spirally rising washer ascending track.

[0030] The end section of the screw ascending track includes a flat shelf and a baffle located at the outer edge of the shelf, and there is a screw slit between the shelf and the baffle through which the screw part of the screw can pass. .

[0031] The working platform is provided with a vertical rotating column 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com