Drawer Flame Arrester

A flame arrester and drawer-type technology, which is applied in fire rescue and other directions, can solve the problem of easy blockage of the flow hole of the fire arrester, achieve the effects of material saving, uniform force, and easy blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

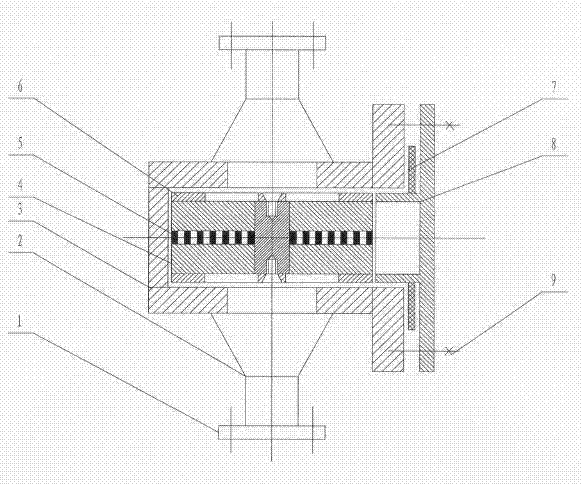

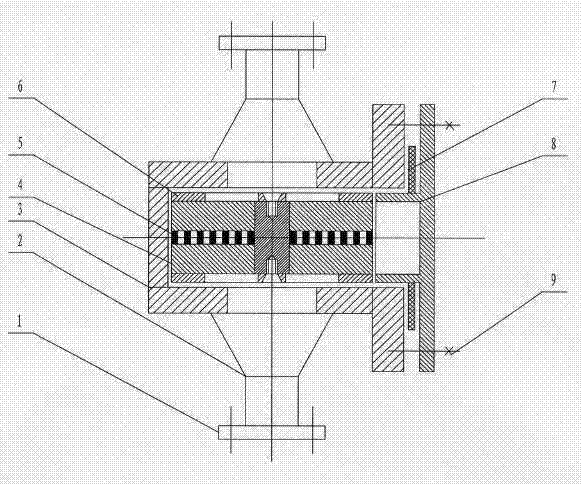

[0028] see figure 1 , A drawer-type flame arrester of the present invention is mainly composed of a housing 3, a fire arresting element 4, an interlayer filler 5, an upper and a lower pressure ring 6, a gland 8 and screws 9.

[0029] The housing 3 has a rectangular base. The housing 3 is provided with a drawer-shaped cavity. The upper and lower parts of the housing 3 are provided with inlets and outlets. The edge of the drawer opening on the side of the housing 3 is provided with protrusions for easy assembly.

[0030] The fire arresting element 4 is composed of several sheets and placed in the cavity of the housing 3 . In the middle layer of the fire retardant element 4, a rectangular interlayer filler 5 is arranged. The interlayer filler 5 is designed as a perforated mesh plate, which is evenly stressed and stable, and is not easily deformed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com