An image analysis method based on principal component analysis and its application to fabric defect detection

A technology of principal component analysis and image analysis, which is used in instruments, character and pattern recognition, computer parts, etc., and can solve the problems of error in detection results, random interference of fabric textures without consideration, and large amount of calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

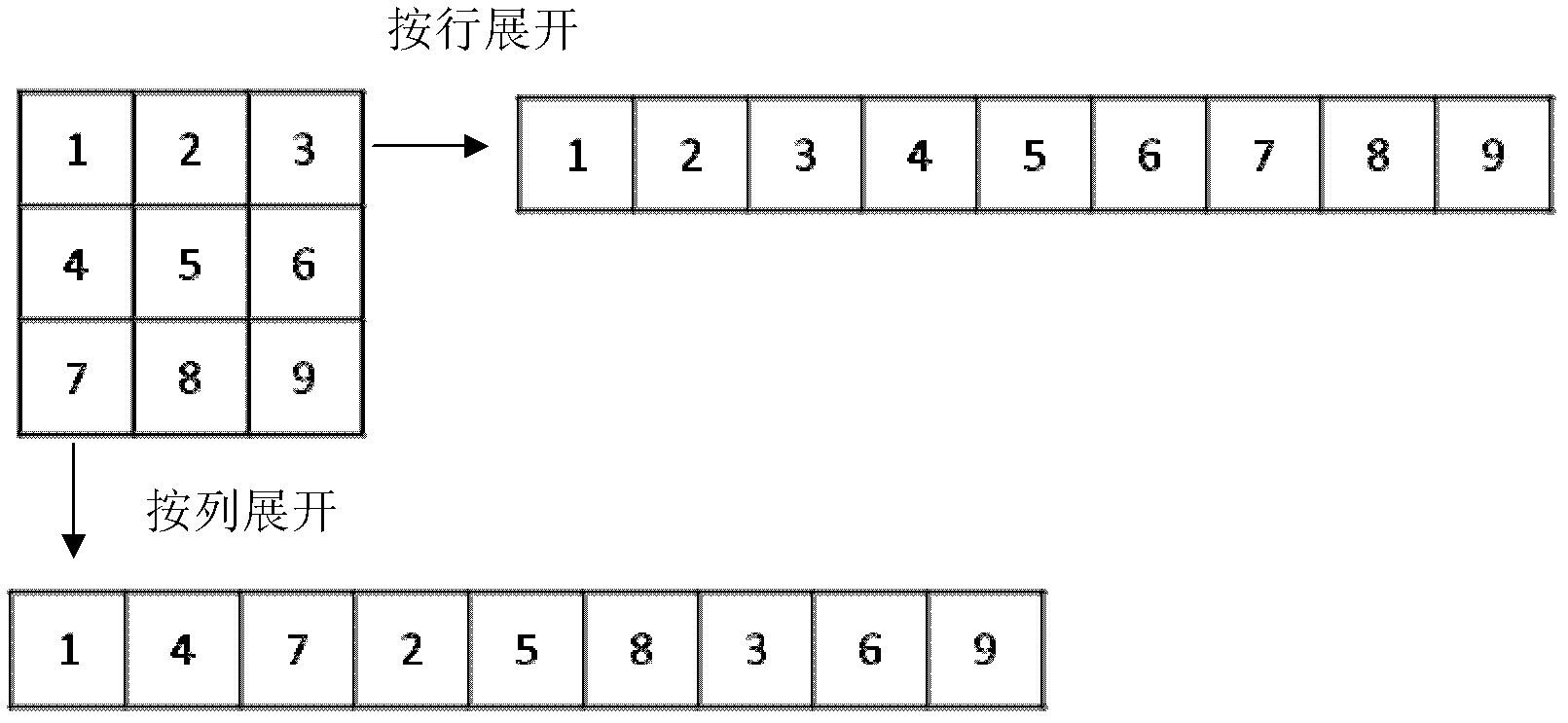

Method used

Image

Examples

Embodiment

[0066] The sample distribution of the six data sets used in the embodiment is shown in the table below:

[0067]

[0068] Among them, the training set A H and A V Respectively by the random vector x of step 1) h and x v Constituted, the number of samples in the present invention is uniformly taken as 600, which is used to calculate the corresponding pivot matrix; training set B H and B V Respectively by the y of step 2) h and y v Constituted, used to calculate the threshold T used for detection α ; test set D H and D V Respectively by the f of the flawed sample in step 3) h and f v Constituted to obtain the missed detection rate.

[0069] Figure 11 ~ Figure 16 The actual detection results of the six data sets used in the implementation are given, in which the false detection rate represented by the abscissa in each example is directly estimated by the confidence level α, and the missed detection rate represented by the ordinate is obtained by taking different c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com