A detection method for identifying static mechanical performance parameters of materials in different regions of welds

A technology of static mechanics and detection methods, applied in the direction of testing material hardness, etc., to achieve the effect of high practical value, widening the scope of use, and strong engineering significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

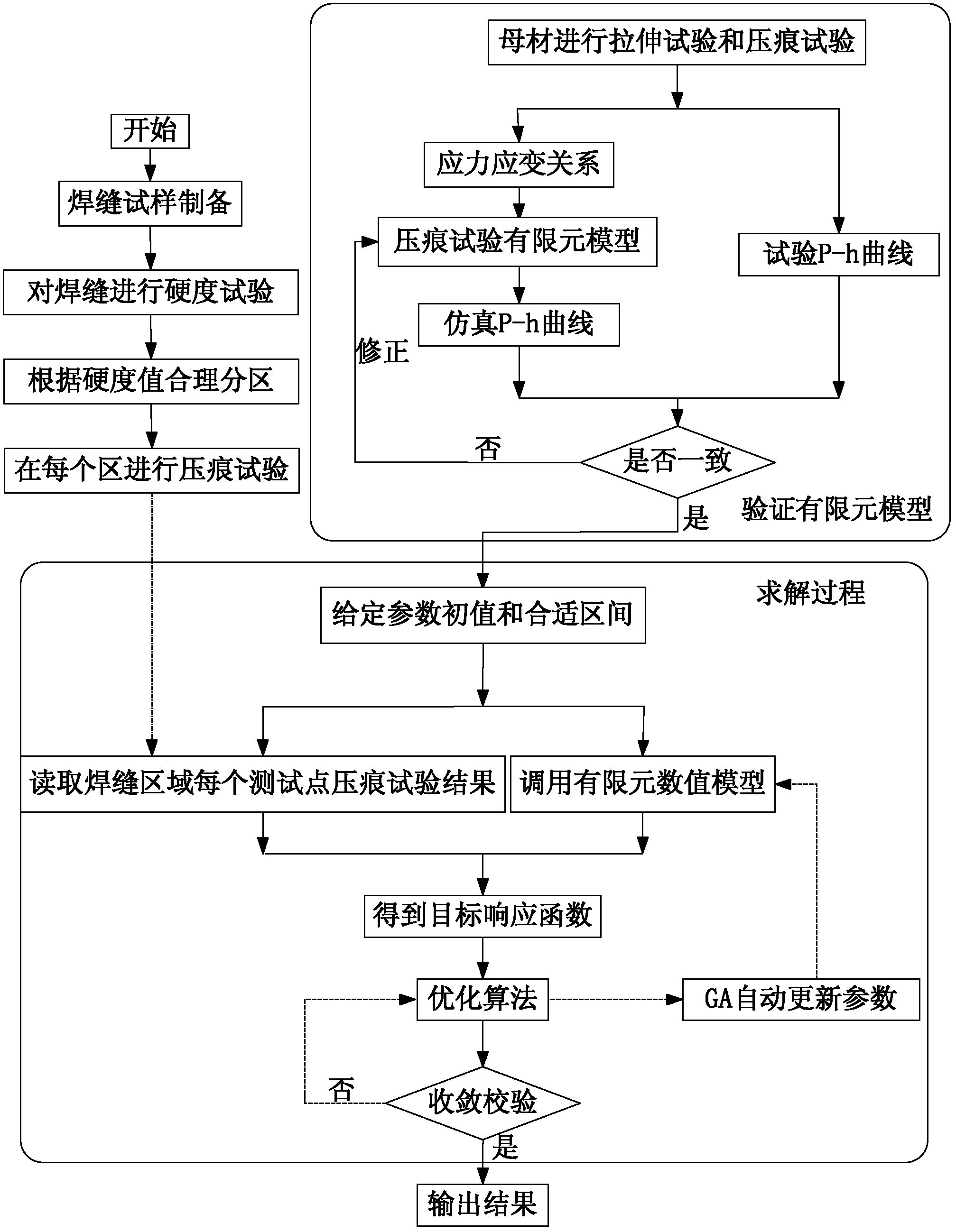

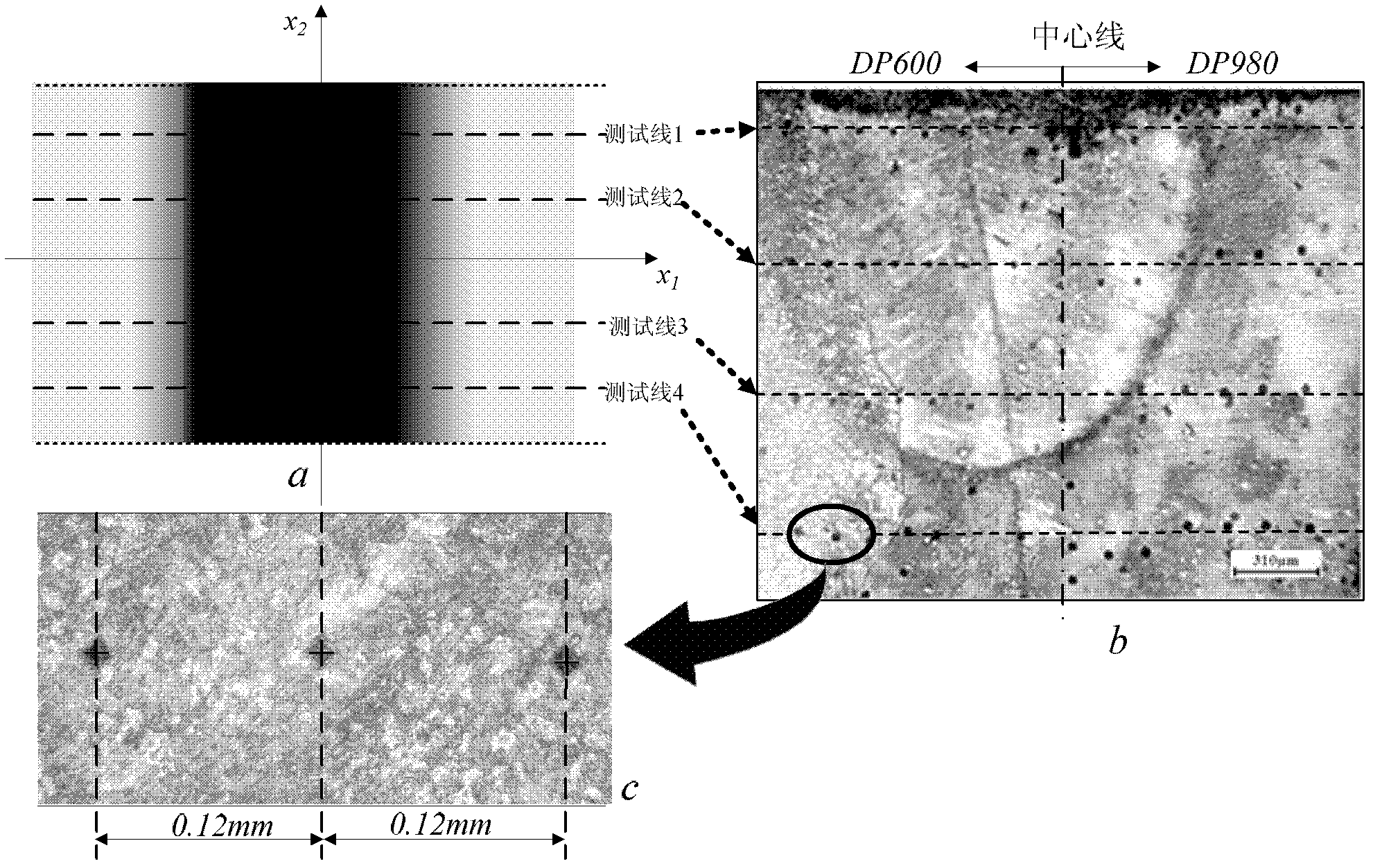

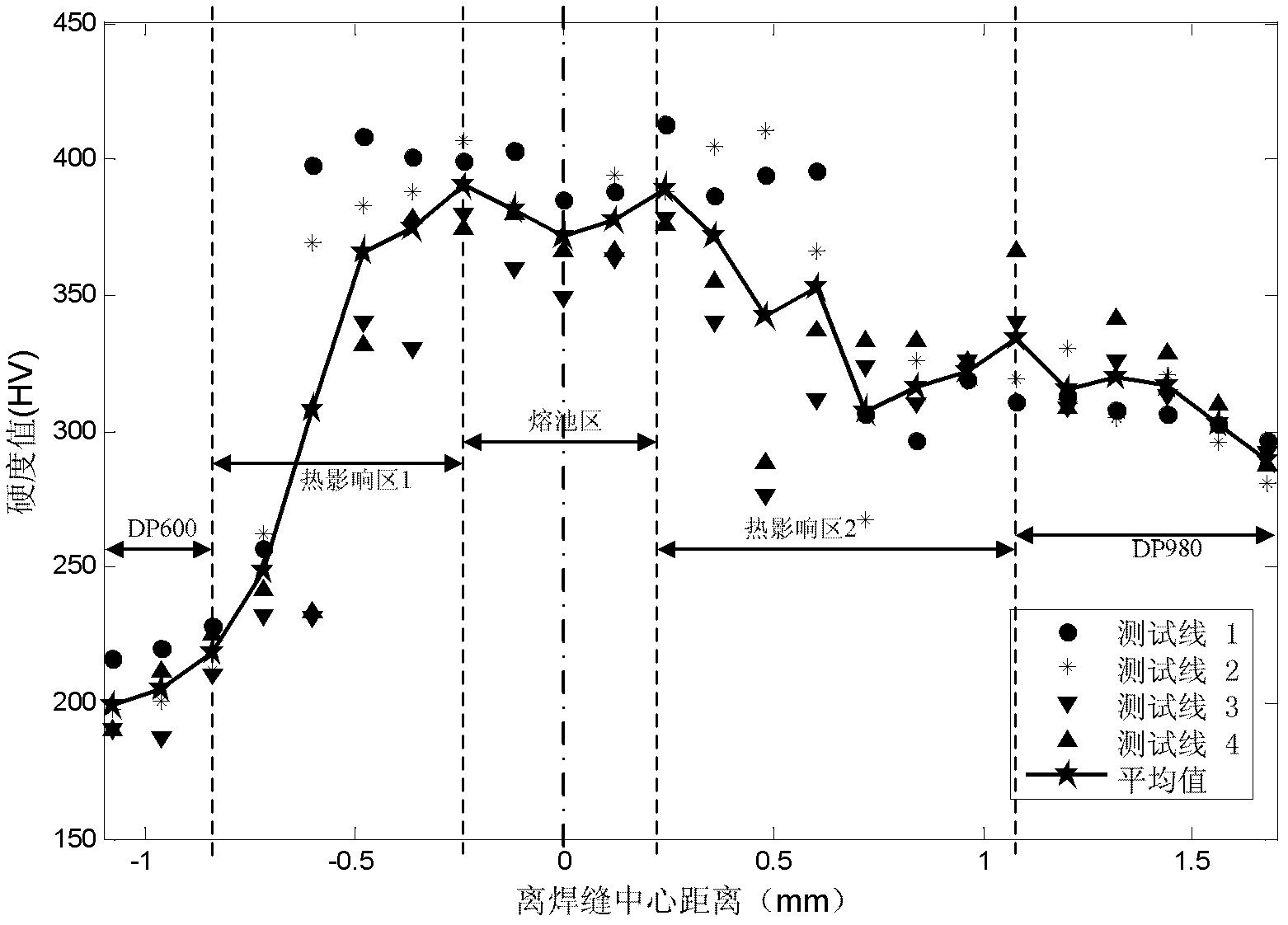

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] Since the constitutive relationship of most engineering polycrystalline metal materials conforms to the power exponential relationship, that is, the hardening curve approximates a parabolic shape. Similarly, for engineering structures formed by a sharp annealing process of cubic lattice metals (steel plates and aluminum alloys, etc.) like welds, they also have a parabolic tensile change curve in the plastic deformation stage, so the calculation used in the embodiments of the present invention The elastoplastic constitutive model of the material is represented by the Hollomon power exponent hardening equation, as shown in formula (1):

[0030] σ = Kϵ n = σ y ϵ y n ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com