Windmill blade structure capable of altering actuated blade area automatically

A technology of blade structure and windmill, applied in the direction of engine, wind turbine, machine/engine, etc., can solve the problems of reducing the working efficiency of windward blades, unable to exert the effect of wind force to the limit, and reducing the driving efficiency of windmill.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

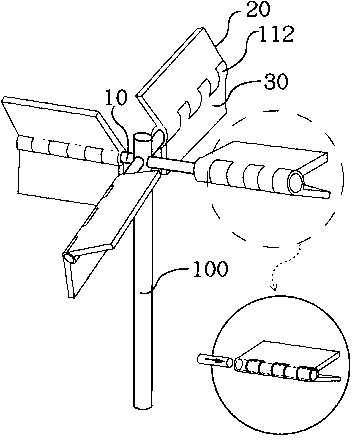

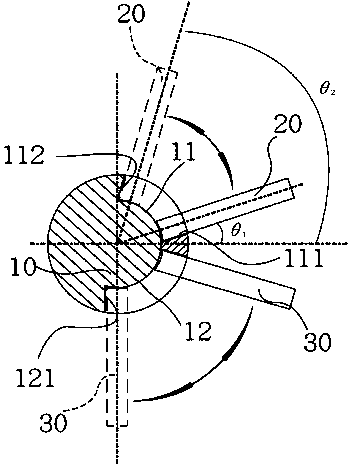

[0016] The present invention relates to a windmill blade structure, as shown in the first to second figures, it mainly includes a main shaft (10), the first end of the main shaft (10) is horizontally fixed on the windmill On the rotating shaft (100); an upper blade (20) and a lower blade (30) are respectively installed on the second end of the main shaft (10).

[0017] An upper arc-shaped groove (11) and a lower arc-shaped groove (12) are formed transversely at the second end of the main shaft (10). The bottom edge and the upper edge of the upper arc-shaped groove (11) are respectively provided with a lower stop part (111) and an upper stop part (112), wherein, the distance between the lower stop part (111) and the horizontal plane The included angle (θ1) is not less than 0 degrees; and the included angle (θ2) between the upper stop portion (112) and the horizontal plane is not greater than 90 degrees. The lower arc-shaped groove (12) has a lower stop portion (121), and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com