A Fully Automatic Adjustable Controller for Draining Oil Tank Bottom Water

A bottom water, fully automatic technology, used in containers, large containers, packaging, etc., can solve the problems of limited discharge, difficult to open the discharge valve, corrosion of oil tanks and pipelines, etc., to achieve easy installation and use, easy manufacturing and processing, Smooth up and down motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

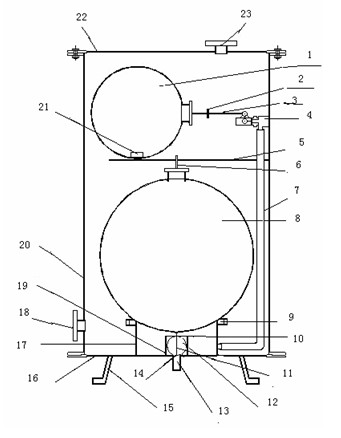

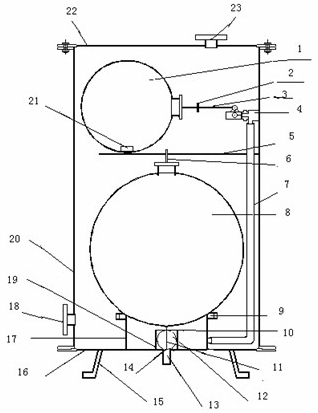

[0018] Accompanying drawing is the embodiment of the present invention.

[0019] Below in conjunction with accompanying drawing, the content of invention is further described:

[0020] refer to figure 1 , figure 2 As shown, a fully automatic adjustable controller for discharging the bottom water of the oil tank, including the oil tank, pipeline, first float, counterweight, connecting rod, float valve, support plate, guide rod, drainage tube, second float Ball, valve seat, second valve barrel, connecting rod, rubber ball, sewage outlet, drain outlet, shell support, shell bottom plate, first valve barrel, water inlet, small hole, shell, magnet, shell upper cover , oil outlet, valve, one end of the housing 20 of the drainage controller is connected with the housing upper cover 22, the housing upper cover 22 is connected with an oil outlet 23, and the other end is connected with the housing bottom plate 16, and the housing bottom plate 16 is connected with a housing support 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com