High-speed intelligent fastening assembly platform system

An assembly platform and fastening device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of improving assembly efficiency, improving production efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

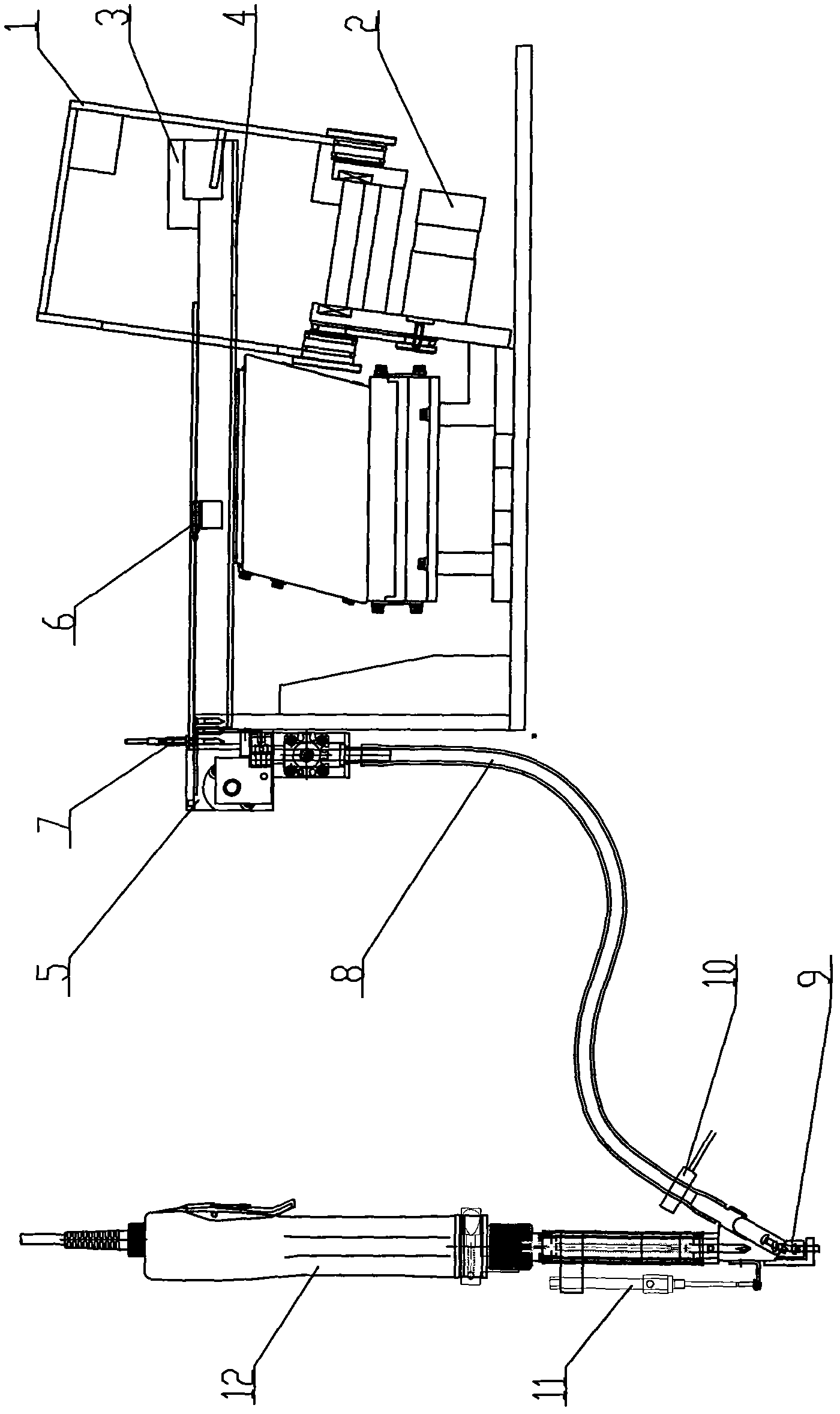

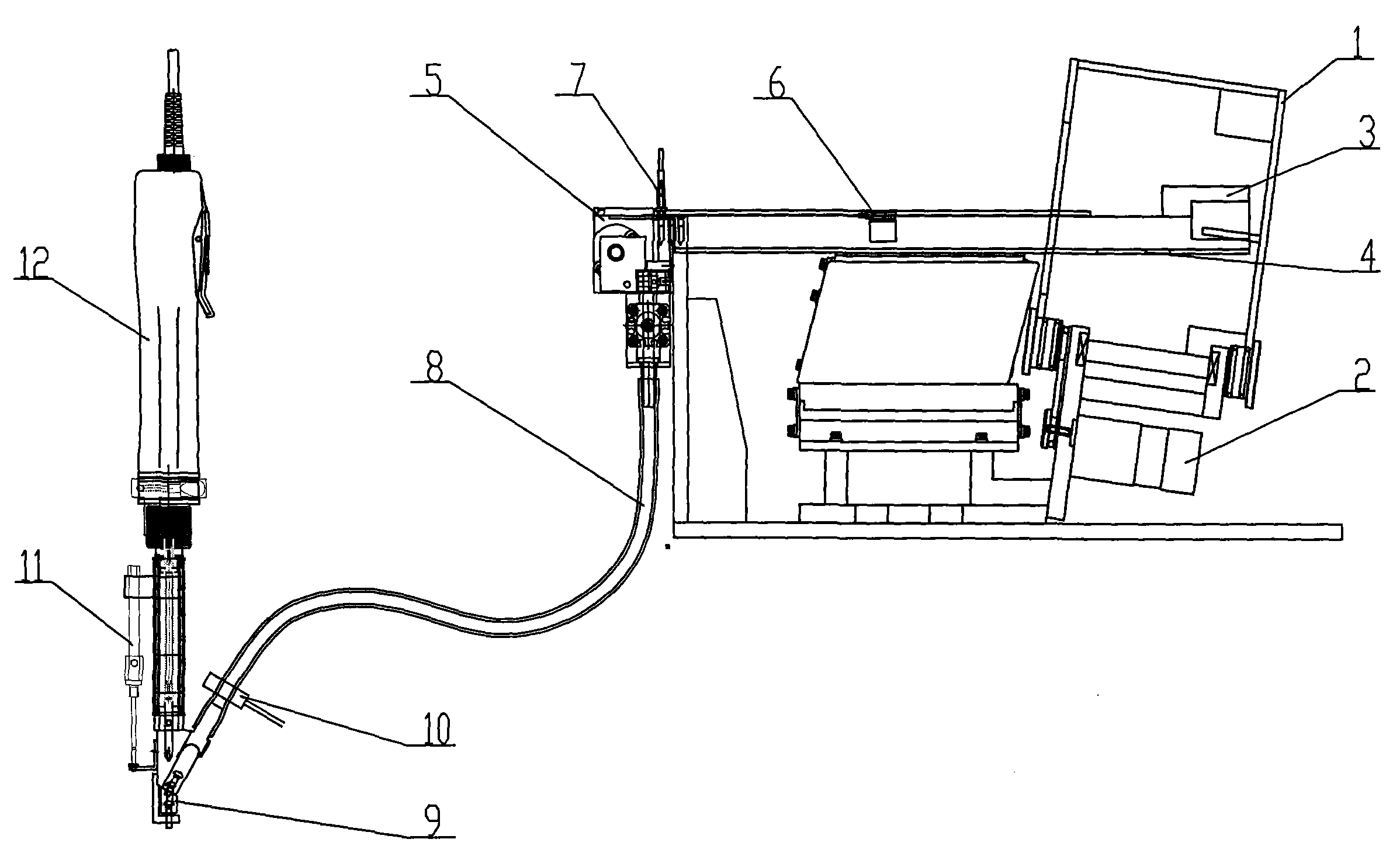

[0020] The high-speed intelligent fastening assembly platform will be described in detail below in conjunction with the embodiments.

[0021] Fastener array device: such as figure 1 As shown, the random fasteners are loaded into the rolling barrel 1, and the micro motor 2 is driven to make the rolling barrel rotate. There are multiple angle blades in the rolling barrel to drive the screws and other fasteners to roll in the storage. Rolling in the barrel 1, it enters the directional sorting structure 3 and the impurity removal groove 4 at the head end of the guide rail through the action of gravity. After directional selection of fasteners, defective removal and removal of impurities, it is then introduced into the linear guide rail of the piezoelectric linear vibration unit. The segment part is compactly sorted and fed through the high-frequency vibration of the piezoelectric linear vibration unit, and is sorted into a fastener array from the end of the guide rail, waiting for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com