Connection assembly for connecting turbine housing to support housing and exhaust gas turbocharger

一种涡轮机壳体、支承壳体的技术,应用在发动机元件、燃气轮机装置、机器/发动机等方向,能够解决不能补偿、加剧壳体热膨胀、气体泄漏等问题,达到好密封效果、防止气体泄漏、实现稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

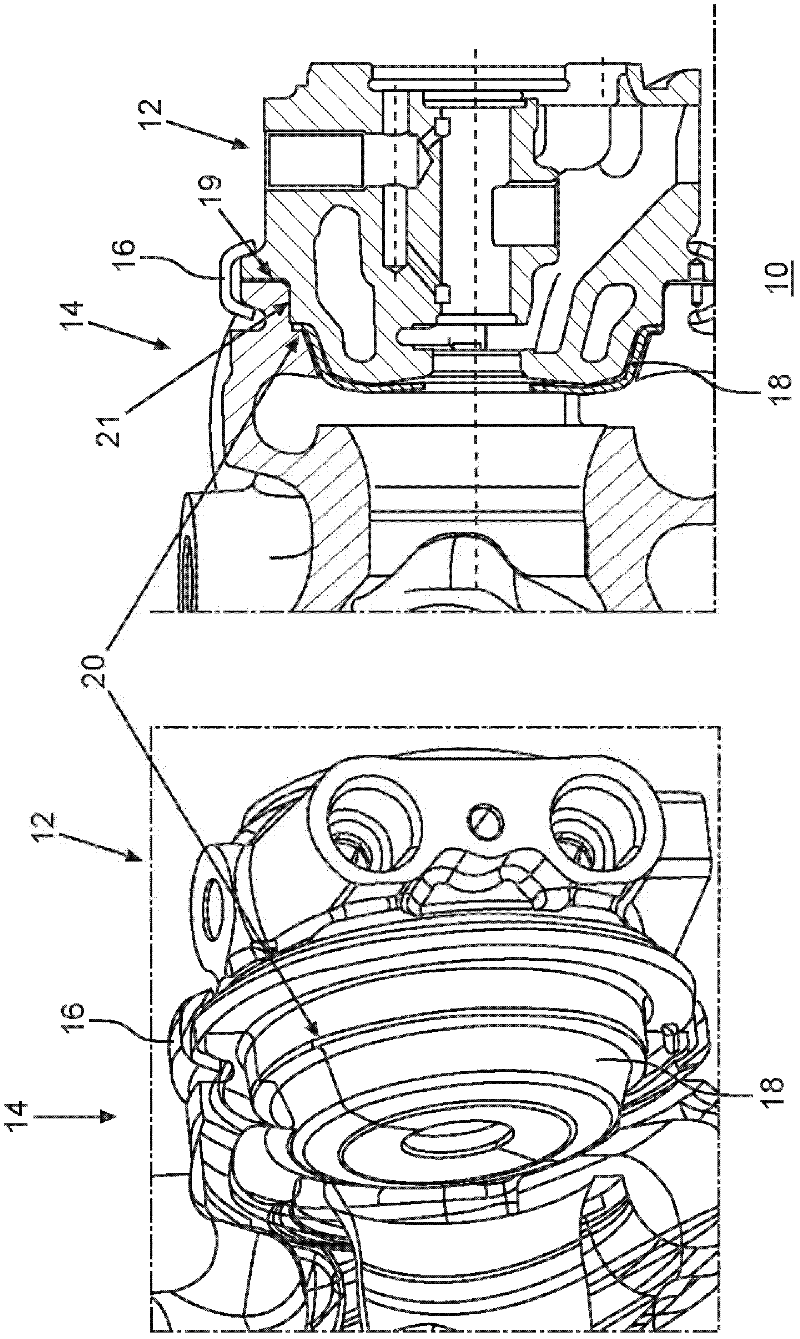

[0040]figure 1 Shown is a prior art connection assembly for connecting the turbine housing of an exhaust-gas turbocharger with a support housing, wherein the thermal insulation is formed by the support housing, the turbine housing and the thermal insulation The seal assembly is positioned in the axial direction towards the turbine housing and thus outside the connection, figure 2 A connection assembly is shown connecting the turbine housing of the exhaust-gas turbocharger with the support housing, wherein the seal assembly is positioned centrally with respect to the connection element and thus with respect to the housing. image 3 show figure 2 The connection assembly of , where the longitudinal section is located in another plane of the connection assembly, thus showing figure 2 Other aspects of connected components.

[0041] figure 2 A connecting assembly 30 is shown, in which the bearing housing 12 ′ and the turbine housing 14 ′ are connected to one another by means ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com