Device for accurately controlling film to advance for microfilm camera

A technology for microfilm and camera, which is applied to electromechanical devices, printing devices, printing equipment, etc., can solve the problems of inability to realize exposure imaging of digital image microfilm cameras, hindering popularization and application, and short life of key components, etc. The requirements of high-resolution technical indicators, stable and reliable transmission synchronization, and stable and reliable noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and preferred embodiment, specific implementation, structure, feature are described in detail as follows:

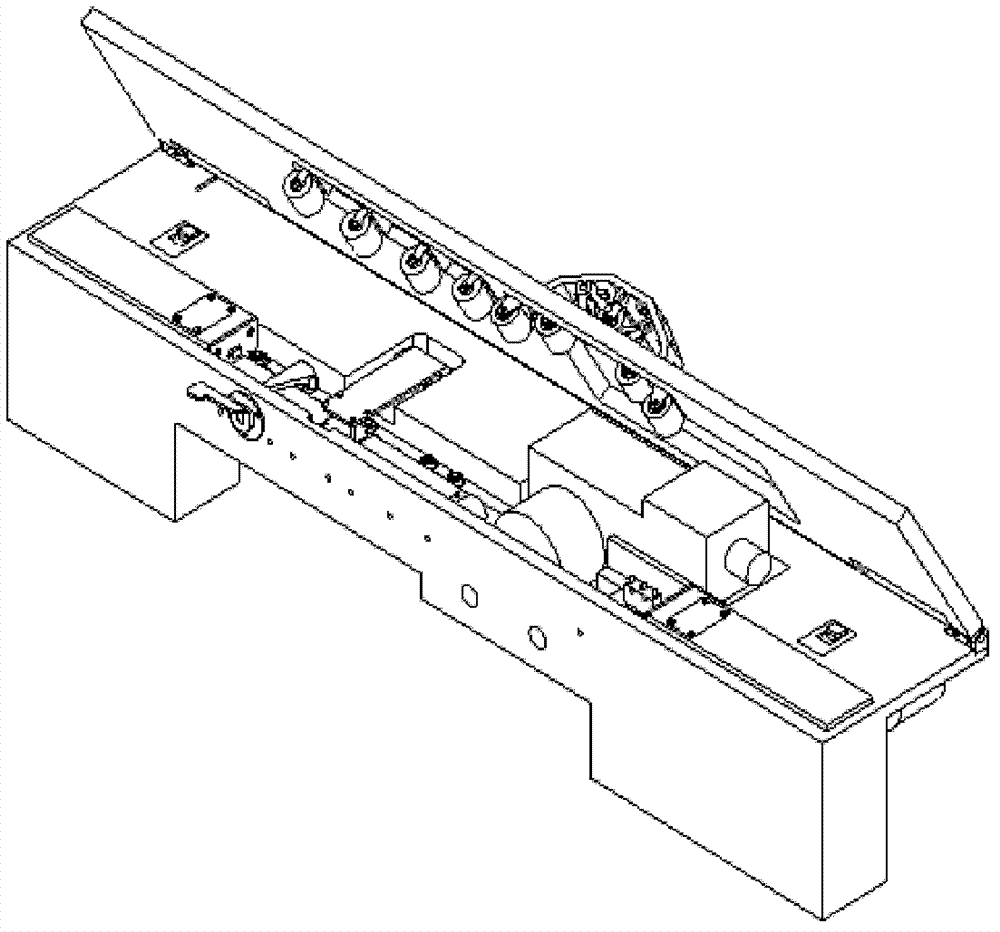

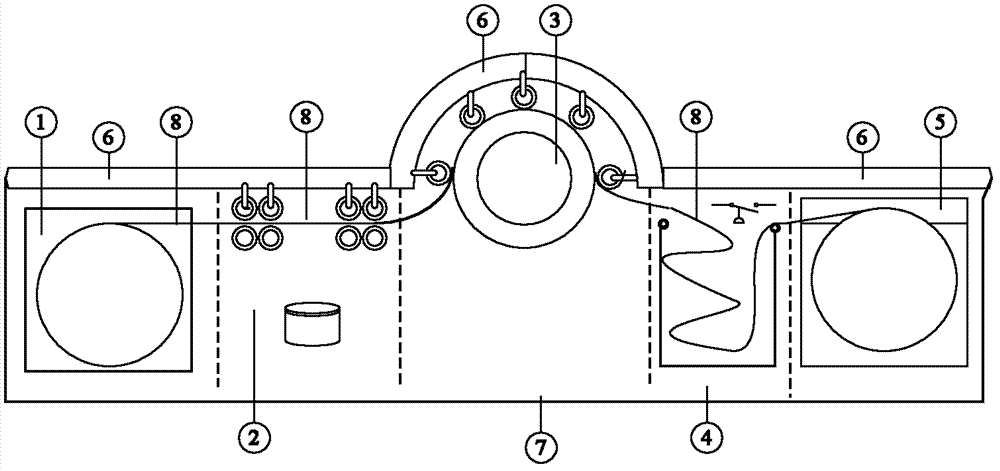

[0018] figure 1 and 2 As shown, the device of the present invention includes an original film box 1, a film exposure area 2, a precise film driving mechanism 3, a film receiving buffer zone 4, a film receiving box 5, a mechanism upper cover 6 and a film traveling mechanism base 7, wherein the original film box 1 and the receiving box 5 are airtight closures made of metal materials with the same structure, which can ensure the safety of the film stored inside and no light leakage. Before the system works, install the original film box 1 and the receiving box 5 with microfilms to the corresponding position. The original film box 1 is used as a cassette for storing the film before exposure, and transports the film to the exposure area 2 smoothly at any time.

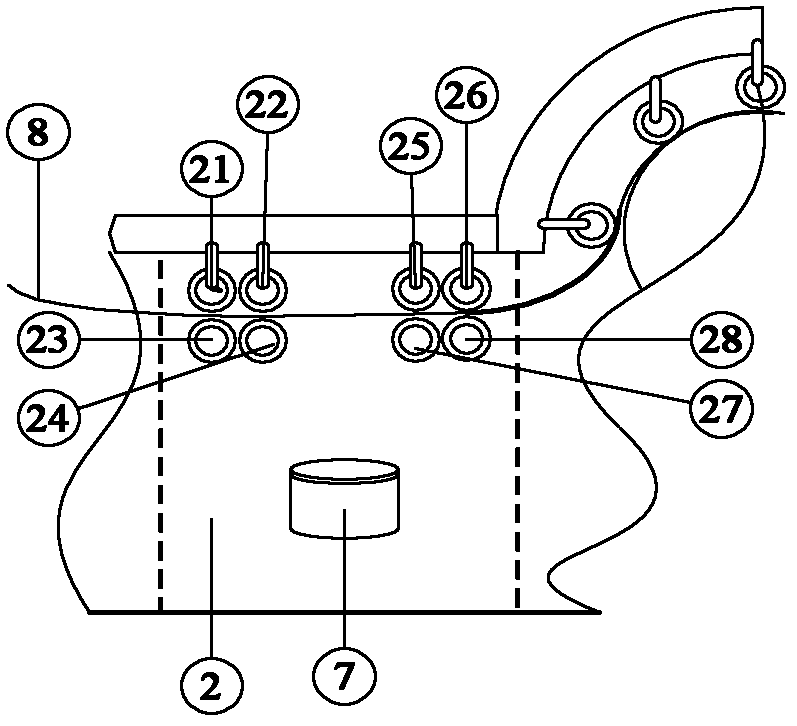

[0019] image 3 It is a structural schematic diagram of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com