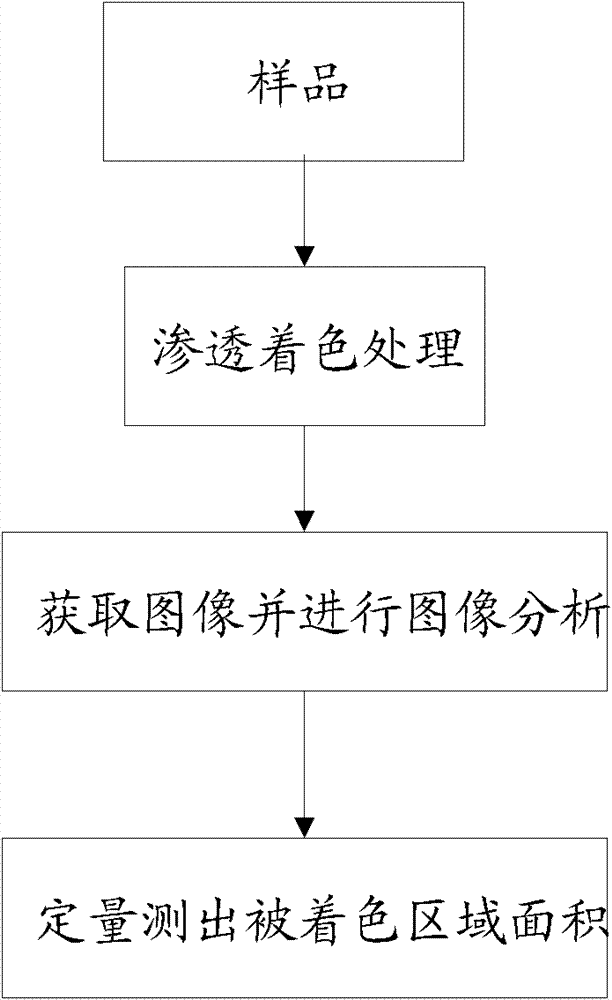

Method for testing and evaluating de-lipping performance of cigarette tipping paper

A technology of cigarette tipping paper and evaluation method, which is applied in the preparation of test samples, measuring devices, image data processing, etc., and can solve the problem of sticky lips, uneven lip-thinning performance of tipping paper, poor lip-thinning performance, etc. problem, to achieve the effect of simple method, easy promotion and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Take a flat piece of cigarette tipping paper and cut it into a 2cm×2cm sample with a paper knife. When cutting, avoid the perforated area. Place the sample with the printed side down and put it in the diluted 1:3 ratio. In the evaporating dish of the ink, use a stopwatch to time the time. After 15 seconds, take out the sample, place the sample printed side down on a clean absorbent paper, and after natural air drying, place the sample flat between two clean glass plates, and use the lens to perpendicular to the sample surface The camera takes a clear picture of the unprinted surface (distal lip surface) of the sample, and uses metallographic analysis software to segment the taken sample photos to separate the unprinted surface (distal lip surface) of the tipping paper sample to be colored. The ratio of the area of the colored area to the area of the sample is calculated to be 10%.

Embodiment 2

[0043] Take a flat piece of cigarette tipping paper and cut it into a sample of 1cm×2cm with scissors. When cutting, avoid the perforated area. Place the sample with the printed side facing down and place the sample with 30% zinc chloride (ZnCl2). ) In the evaporating dish of the solution, use a stopwatch to time the time, take out the sample after 10 seconds, dry the sample in a drying oven, place the dried sample in the middle of two clean glass plates, and use the lens to connect perpendicular to the sample surface The computer's camera obtains a clear picture of the unprinted surface (distal lip surface) of the sample, and uses professional image analysis and processing software to segment the taken sample photos to separate the unprinted surface (distal lip surface) of the tipping paper sample that is colored , Calculated that the area of the colored area accounts for 30% of the sample area.

Embodiment 3

[0045] Qualitative analysis of the lip sparse performance of 5 tipping paper samples: Take one sample from 5 samples and cut it into a 1cm×2cm sample with scissors. When cutting, avoid the perforated area and place the sample with the printed side facing down. In a beaker with Herzberg stain solution, use a timer, take out the sample after 30 seconds, dry the sample in a drying oven, place the dried sample in the middle of two clean glass plates, and use the lens to perpendicular to the sample surface The camera connected to the computer obtains a clear picture of the unprinted surface (distal lip surface) of the sample, and uses professional image analysis and processing software to segment the taken sample photos, and separate the unprinted surface (distal lip surface) of the tipping paper sample is colored Repeat the above steps to obtain colored photos of 5 samples, observe the area of the colored areas, and qualitatively analyze the pros and cons of the lip thinning perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com