Air-coupled ultrasonic testing transducer sound field characteristic measuring device

An ultrasonic transducer, air coupling technology, used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention is described in detail below:

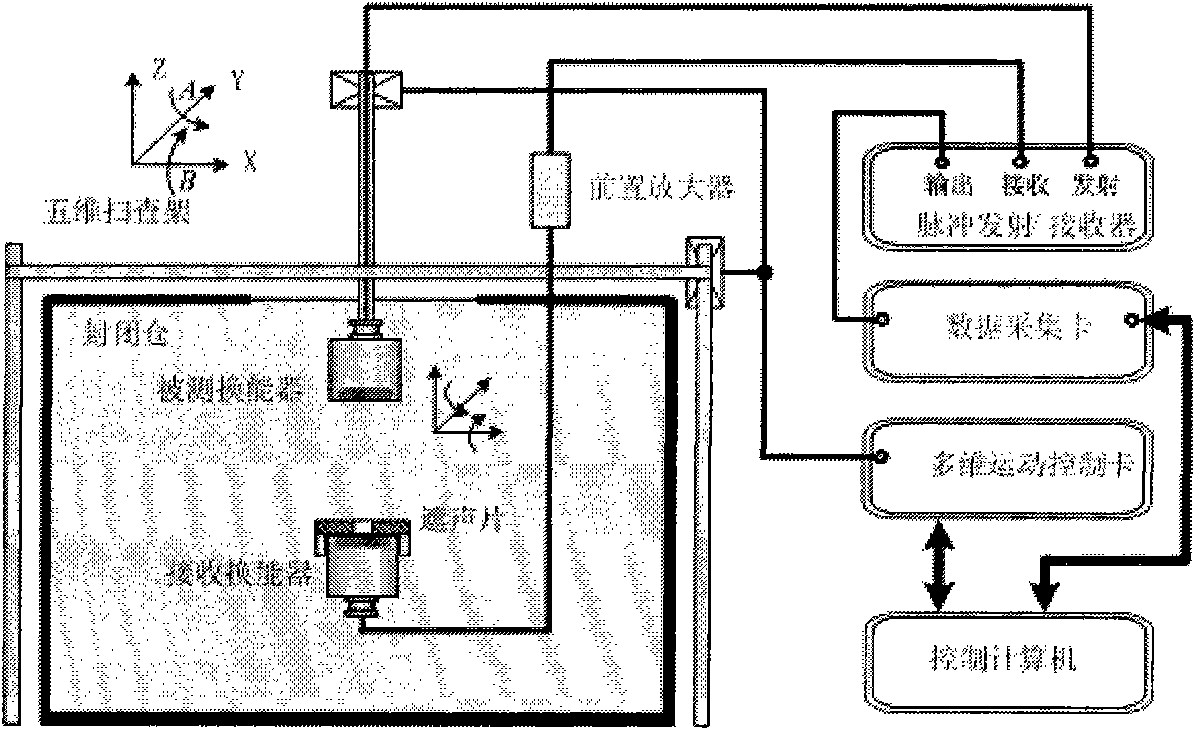

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the sound field characteristic measurement device mainly includes: ultrasonic transceiver and signal acquisition system, scanning mechanism, motion control system, sound axis alignment mechanism, micro-hole sound shield. The whole measuring device is supported by the scanning mechanism.

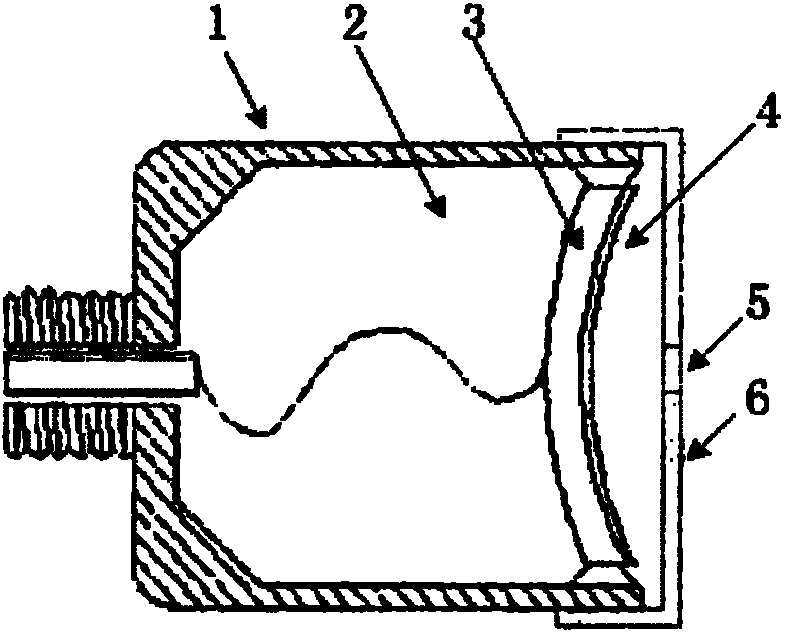

[0022] figure 2 1 is the shell of the air-coupled ultrasonic transducer, 2 is the air backing, 3 is the piezoelectric chip, 4 is the surface protection layer, 5 is the sound shield of the receiver, and 5 is the sound transmission aperture of the sound shield.

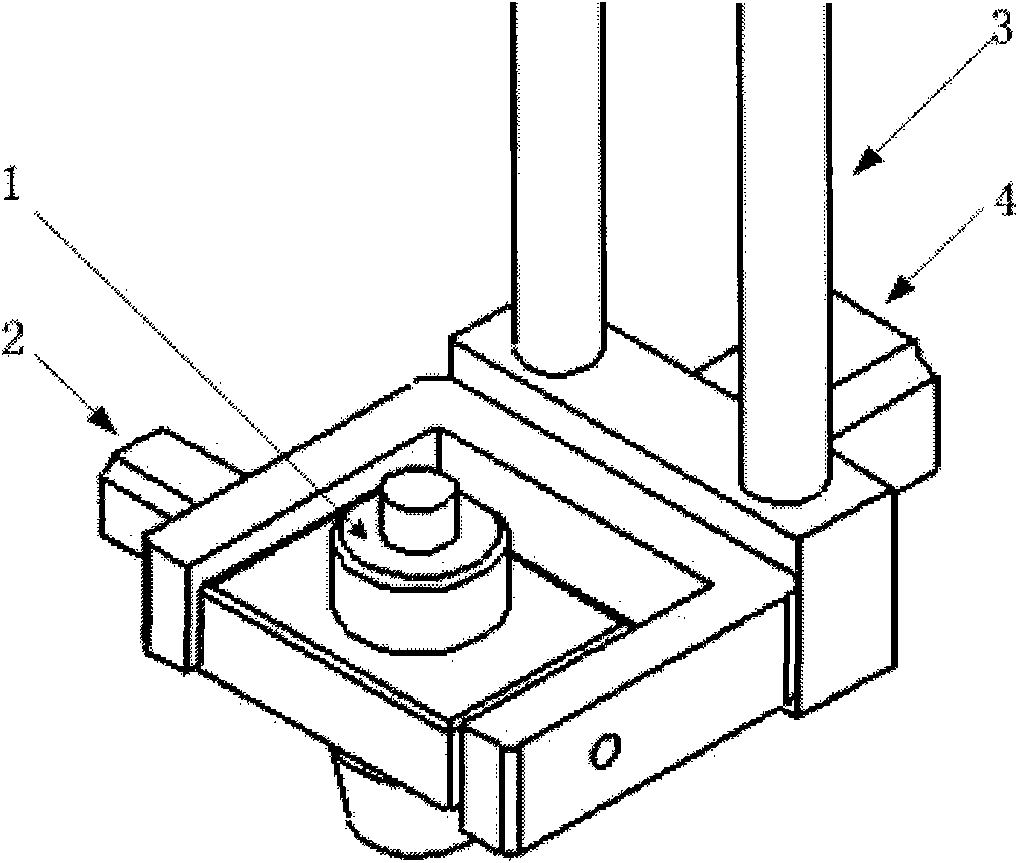

[0023] image 3 Among them, 1 is the air-coupled ultrasonic transducer to be tested, 2 is the A-axis attitude adjustment motor, 3 is the connecting guide rod, and 4 is the B-axis attitude adjustment motor. By adjusting the A-B axis position and attitude of the sound axis ali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com