Passive quantitative interceptor

A technology of interceptor and positioning shaft, which is applied to instruments, measuring capacity, measuring devices, etc., can solve the problems of consumers' unwillingness to buy, user safety hazards, and complicated operation, so as to eliminate hidden dangers of electricity consumption and ensure reliability. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

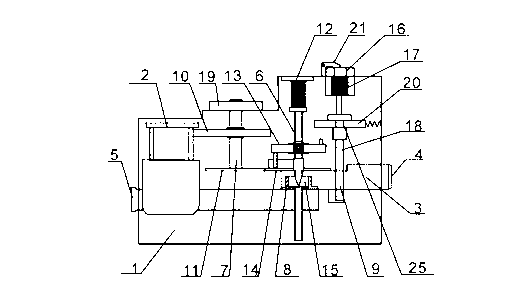

[0030] Such as figure 1 As shown, after the interceptor is installed, open the lock key 21, press the valve button 16 to connect the pipeline, the lower end of the closing spring 17 is connected to the valve body 1, and the upper end is connected to the valve button 16, and the closing spring 17 is pressed when the valve button 16 is pressed. When it is pressed tightly, there is liquid passing through the interceptor, and the liquid drives the impeller to rotate from the water inlet 5 through the guidance of the water meter 2 inner guide cover, and the rotation of the impeller drives the positioning gear 10 to rotate at a low speed through the speed change of the gear set. The liquid enters the z-shaped outlet pipe 3, and the crank arm of the outlet pipe 3 is provided with a piston 15 fixedly connected with the floating shaft 6. The piston 15 is arranged in the piston sleeve 8, and the piston 15 can slide in the piston sleeve 8, and the liquid flows When water pressure is gene...

Embodiment 2

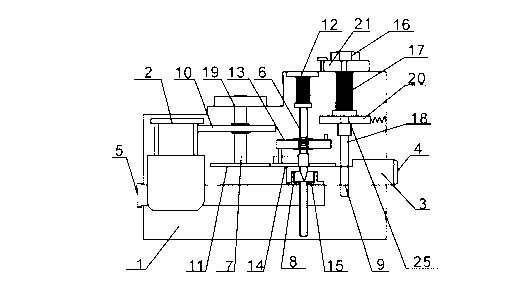

[0034] Such as figure 2 As shown, after the interceptor is installed, open the lock key 21, pull up the valve button 16 to connect the pipeline, the lower end of the closing spring 17 is connected to the valve core 18, and the upper end is fixed on the valve body 1, and the closing spring 17 is pulled on the valve button 16. When it is stretched, there is liquid passing through the interceptor, and the liquid drives the impeller to rotate from the water inlet 5 through the guidance of the water guide cover in the water meter 2, and the rotation of the impeller drives the positioning gear 10 to rotate at a low speed through the speed change of the gear set. The liquid enters the z-shaped outlet pipe 3, and the crank arm of the outlet pipe 3 is provided with a piston 15 fixedly connected with the floating shaft 6. The piston 15 is arranged in the piston sleeve 8, and the piston 15 can slide in the piston sleeve 8, and the liquid flows When water pressure is generated, the pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com