Hydraulic automatic gear shifting device of crawler-type engineering machinery and control method thereof

A technology for automatic gear shifting and engineering machinery, applied in the direction of transmission control, mechanical equipment, components with teeth, etc., to achieve high work efficiency and work reliability, improve comprehensive performance, ensure fuel economy and driving comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

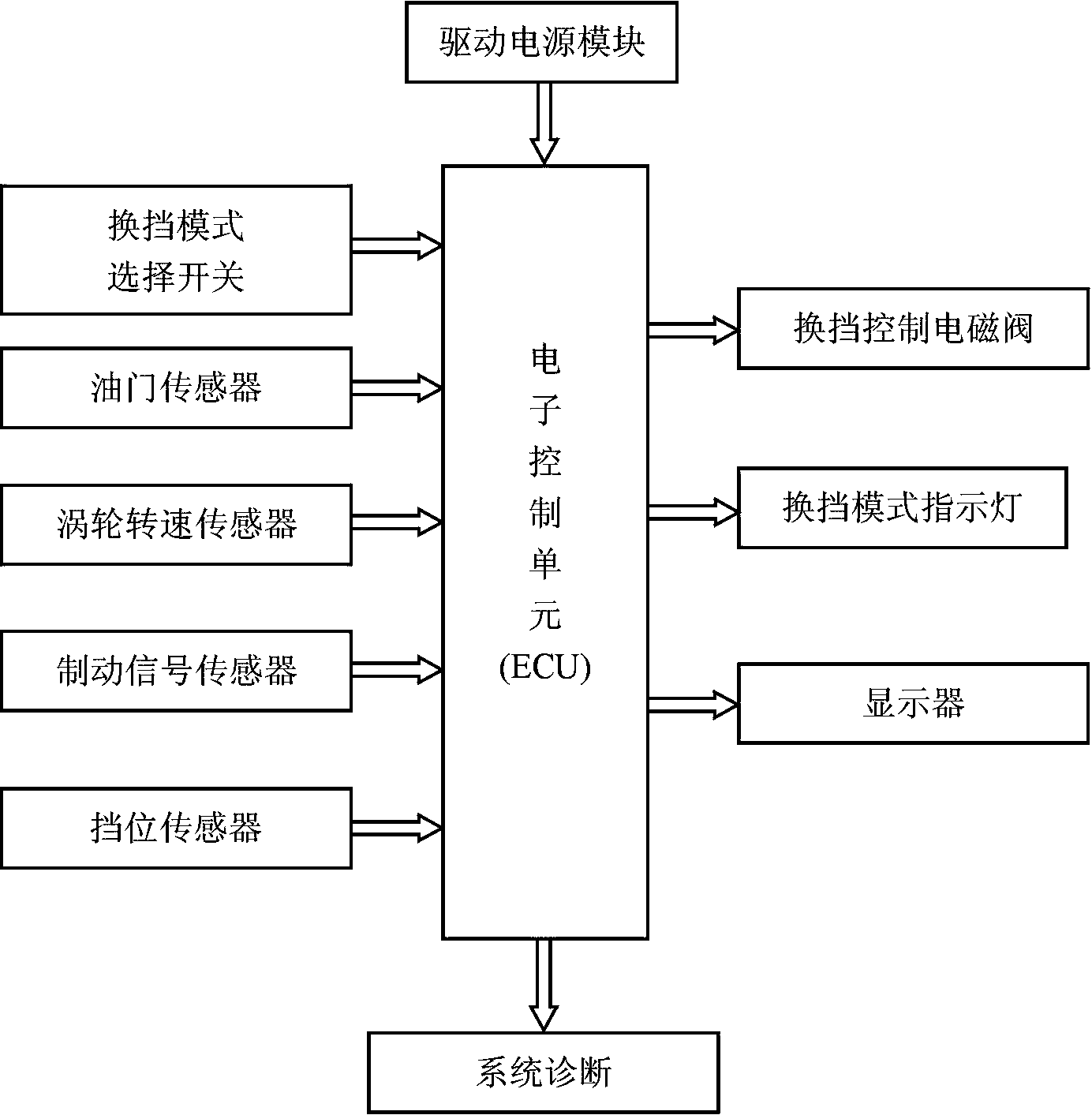

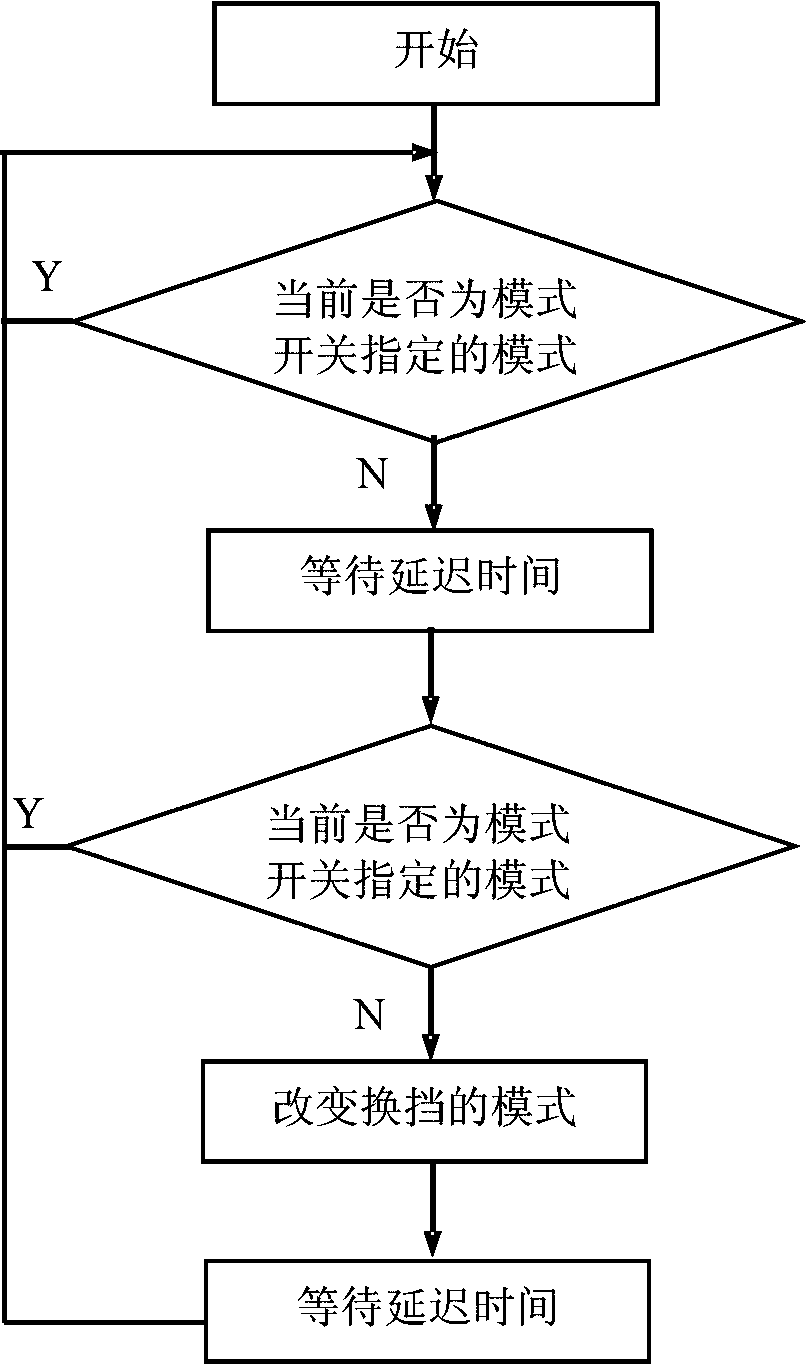

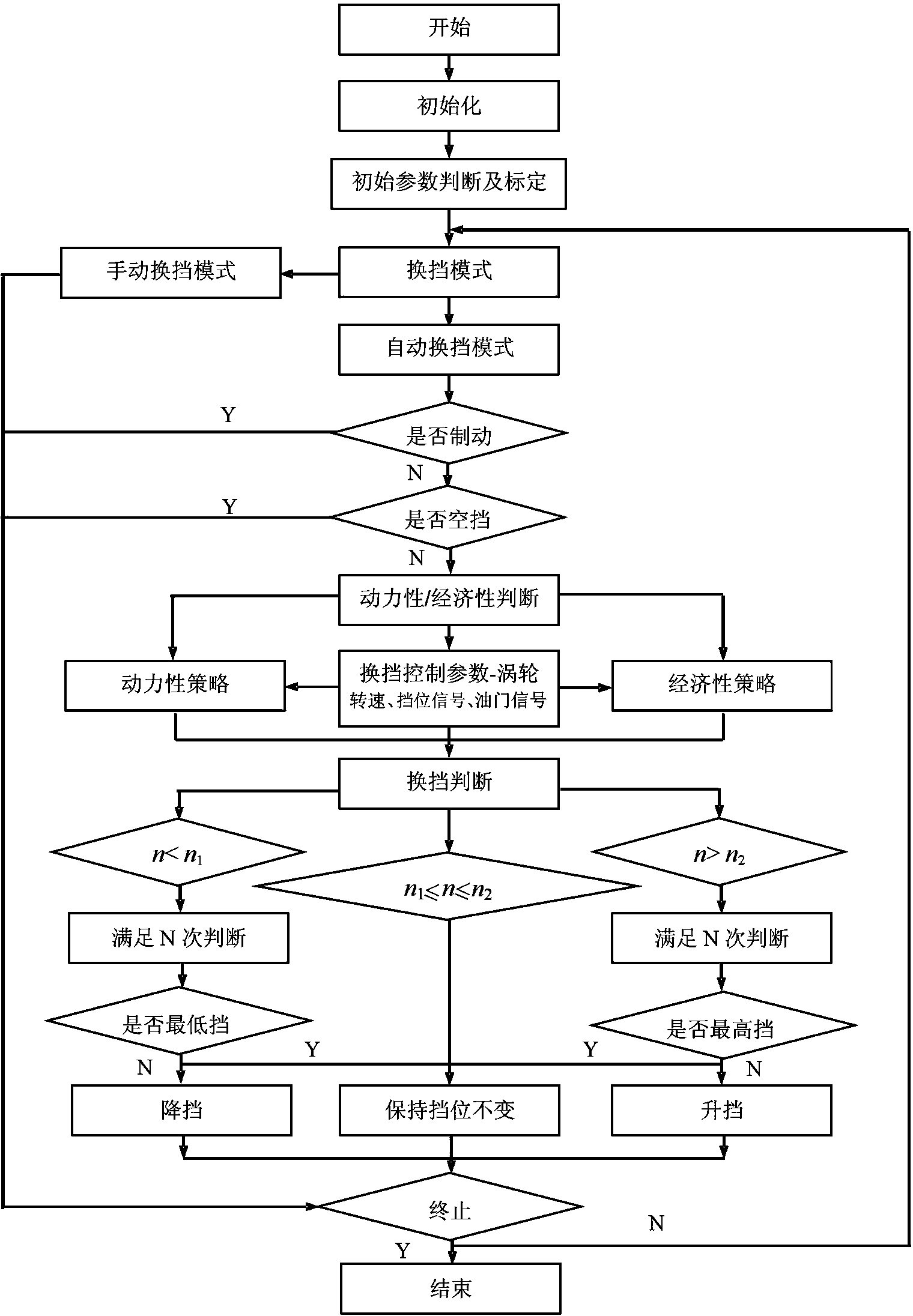

[0035] Now refer to the attached figure 1 , attached figure 2 And attached image 3 , be described as follows in conjunction with embodiment: for being able to further understand content, characteristic of the present invention, take bulldozer as embodiment, provide a kind of hydraulic automatic shifting device that can realize bulldozer, and cooperate accompanying drawing to describe in detail as follows:

[0036] as attached figure 1As shown, a crawler-type engineering machinery hydraulic automatic gear shifting device according to the present invention includes: a turbine speed sensor, an accelerator signal sensor, a shift mode selection switch, a gear signal sensor, an electronic control unit (ECU), a system Moving signal sensor, driving power supply, electro-hydraulic shifting device. Information units such as the shift mode selection switch, turbine speed sensor, throttle signal sensor, brake signal sensor and gear signal sensor collect data, and input the obtained s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com