Blade-autorotation windmill

A blade and windmill technology, applied in the field of windmills with self-rotating blades, can solve problems such as blade direction adjustment, and achieve the effects of reducing wind resistance, smooth and fast operation, and scientific and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

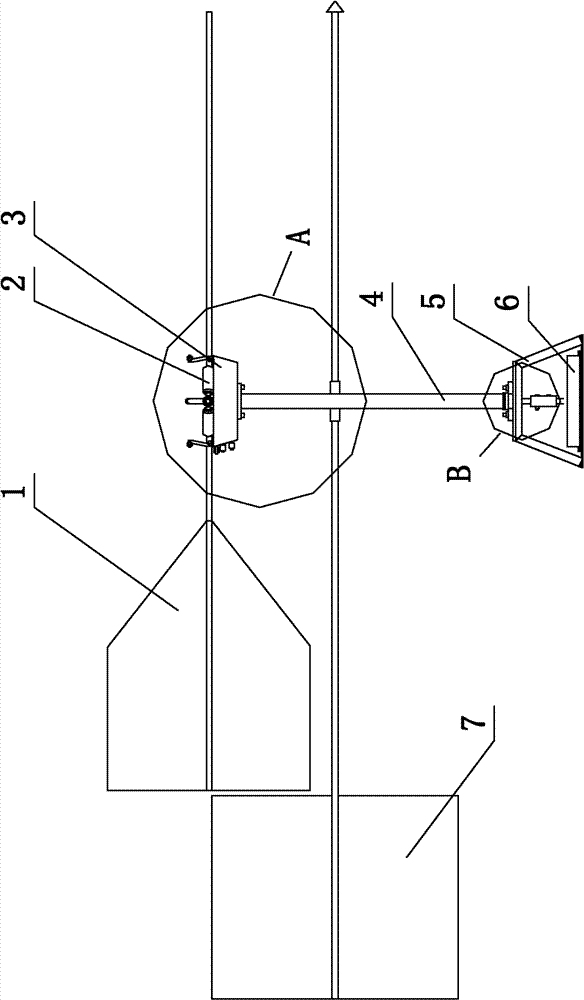

[0023] A windmill with rotatable blades, including blades 1, tower 4, base 5, and generator 6. Its innovation lies in: it also includes a blade rotation control mechanism 3 installed on the top of the tower, and a blade rotation control mechanism installed in the blade rotation control mechanism. Hub 2, and the steering device 7 installed on the tower.

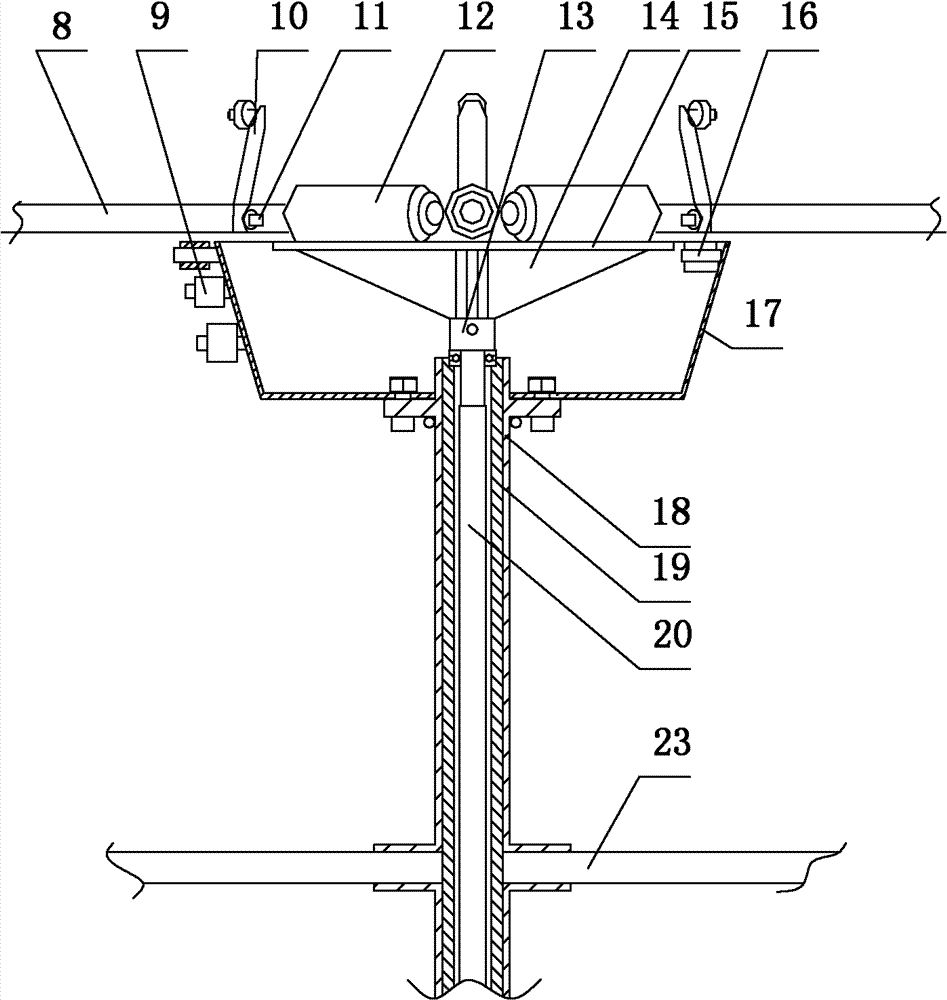

[0024] The tower frame is composed of a vertical shaft 20, a fixed sleeve 19, and a rotating sleeve 18. The fixed sleeve is fixed to the base, the vertical shaft is rotated in the fixed sleeve and the bottom end is connected to the generator, and the rotating sleeve is installed outside the fixed sleeve. . A bearing 25 is installed between the rotating sleeve and the fixed sleeve, and a bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com