Sewage reuse treatment method for power plant circulating water

A treatment method and technology for circulating water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve problems such as pressure difference rise, influence of operation stability, and decrease of desalination rate. , to achieve the effect of reducing the frequency of chemical cleaning, extending the operating cycle and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

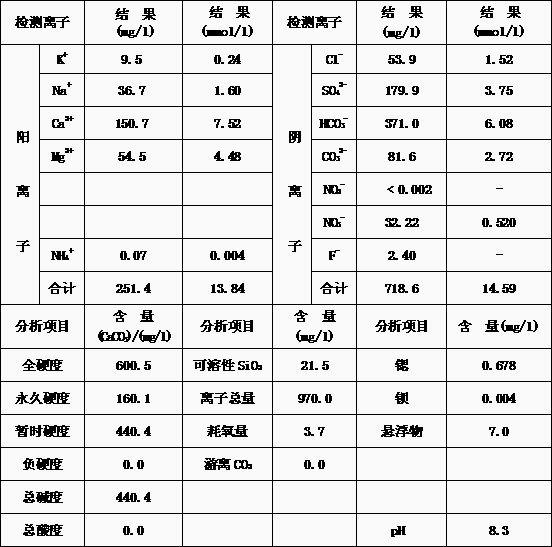

[0021] (1) Set the water volume to 200m 3 / h circulating water sewage is injected into the mechanical agitation acceleration clarification tank, and its hardness value and alkalinity value are measured to be 10mmol / L and 6mmol / L respectively, and the difference between the hardness value and alkalinity value is greater than 3mmol / L, so add carbonic acid first Sodium makes the difference between the hardness value and the alkalinity value less than 1mmol / L, and then add quicklime to the above-mentioned circulating water to soften, so that the concentration of hydroxide in the circulating water is 0.1-0.3mmol / L, and then add it to the softened circulating water Add polyferric sulfate and polyacrylamide for coagulation and clarification treatment, the addition amount of polyferric sulfate and polyacrylamide is 40mg / L and 1.0mg / L respectively; the mechanical agitation acceleration clarification tank adopts Ф14300 mechanical agitation acceleration clarification tank 1 Taiwan, the d...

Embodiment 2

[0034] In this embodiment, the hardness value and alkalinity value of circulating water sewage are 7mmol / L and 6mmol / L respectively, and the difference between hardness value and alkalinity value is less than 3mmol / L. The concentration is 0.1-0.3mmol / L; The addition amount of polyferric sulfate and polyacrylamide is 20mg / L and 0.6mg / L respectively; Other steps are with embodiment 1. The water quality of the reverse osmosis produced water in this embodiment also meets the reuse standard.

Embodiment 3

[0036] In this embodiment, the hardness value and alkalinity value of circulating water sewage are 9mmol / L and 6mmol / L respectively, and the difference between hardness value and alkalinity value is not more than 3mmol / L. The root concentration is 0.1-0.3mmol / L; the addition amount of polyferric sulfate and polyacrylamide is 10mg / L and 2mg / L respectively; other steps are the same as in Example 1. The water quality of the reverse osmosis produced water in this embodiment also meets the reuse standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com