A method and equipment for treating melamine wastewater by ultrafiltration membrane

A technology of melamine and ultrafiltration membranes, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as environmental pollution and waste of resources, and achieve high atom economy, Resource saving and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

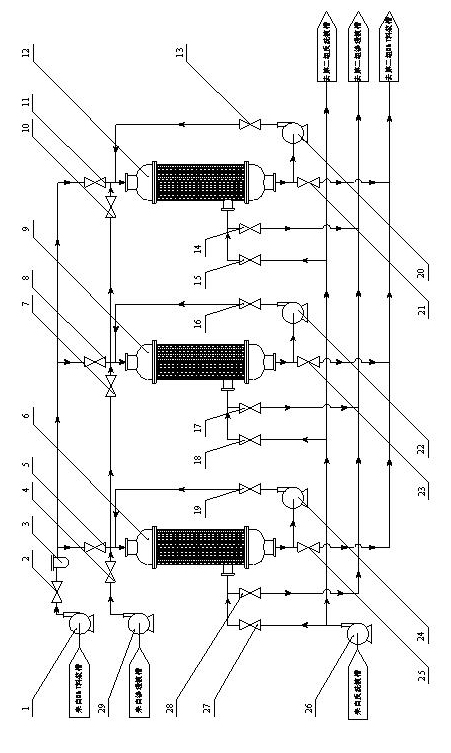

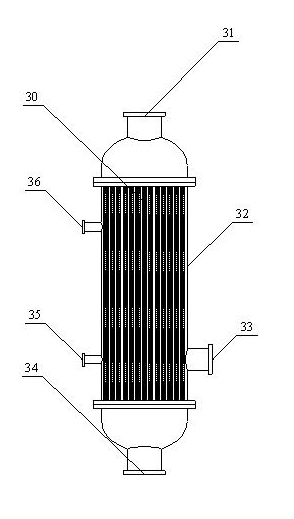

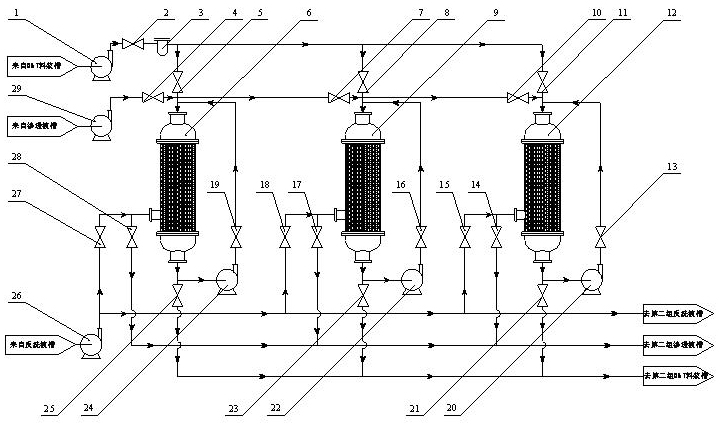

[0019] combined with figure 1 and attached figure 2 , the working process of the method and equipment of ultrafiltration membrane processing melamine waste water of the present invention is described in detail:

[0020] The ultrafiltration equipment used in the present invention consists of an ultrafiltration membrane system, a feed pump, a circulation pump, a prefilter, valves and connecting pipelines. The ultrafiltration system is composed of three ultrafiltration membrane filters (6), (9) and (12) connected in series, and each ultrafiltration membrane filter is composed of a casing (32) and parallel module blocks (30). The module block (30) is composed of a membrane substrate and an ultrafiltration membrane. The membrane matrix is composed of α-Al with macroporous structure 2 o 3 It consists of several parallel channels; the ultrafiltration membrane is composed of one or more layers of zirconium and titanium metal oxides, and the ultrafiltration membrane covers the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com