Adsorption material for removing anions in water and preparation method thereof

An adsorption material and anion technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of high regeneration frequency of activated carbon, increased use cost, short saturation period, etc., and achieve a large amount of surfactant. , less energy consumption, not easy to desorb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

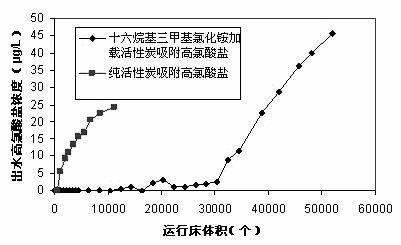

Image

Examples

Embodiment 1

[0025] A preparation method for an adsorption material for removing anions in water, comprising the steps of:

[0026] (1) Weigh 0.064g of cationic surfactant cetyltrimethylammonium chloride and dissolve it in 200mL of deionized water, the concentration of cationic surfactant is 1mmol / L, add 0.1mol / L dilute hydrochloric acid solution dropwise Adjust the pH value of the solution to 3.0 to obtain a cationic surfactant solution;

[0027] (2), 0.5g pitch activated carbon material (pore volume 0.3mL / g, specific surface area 780m 2 / g) Disperse in the 200mL cationic surfactant solution obtained in step (1), at normal temperature and pressure, use a magnetic stirring device to disperse the activated carbon particles uniformly and let stand for 5h;

[0028] (3), the mixed solution after step (2) standing still is filtered in the filter device, the activated carbon is separated from the mixed solution, washed with deionized water and dried, and the obtained black granular activated ca...

Embodiment 2

[0030] A preparation method for an adsorption material for removing anions in water, comprising the steps of:

[0031] (1) Weigh 0.064g of cationic surfactant cetyltrimethylammonium chloride and dissolve it in 200mL of deionized water. The concentration of cationic surfactant is 1mmol / L, and add 0.1mmol / L dilute hydrochloric acid solution Adjust the pH value of the solution to 7.0 to obtain a cationic surfactant solution;

[0032] (2), 0.5g pitch activated carbon material (pore volume 0.3mL / g, specific surface area 780m 2 / g) Disperse in the 200mL cationic surfactant solution obtained in step (1), at normal temperature and pressure, use a magnetic stirring device to disperse the activated carbon particles uniformly and let stand for 5 h;

[0033] (3), the mixed solution after step (2) standing still is filtered in the filter device, the activated carbon is separated from the mixed solution, washed with deionized water and dried, and the obtained black granular activated carbo...

Embodiment 3

[0035] A preparation method for an adsorption material for removing anions in water, comprising the steps of:

[0036] (1) Weigh 0.064g of cationic surfactant cetyltrimethylammonium chloride and dissolve it in 200mL of ionized water. The concentration of cationic surfactant is 1mmol / L, and add 0.1mol / L sodium hydroxide solution dropwise Adjust the pH value of the solution to 10.0 to obtain a cationic surfactant solution;

[0037] (2), 0.5g pitch activated carbon material (pore volume 0.3mL / g, specific surface area 780m 2 / g) Disperse in the 200mL cationic surfactant solution obtained in step (1), at normal temperature and pressure, use a magnetic stirring device to disperse the activated carbon particles uniformly and let stand for 5h;

[0038] (3), the mixed solution after step (2) standing still is filtered in the filter device, the activated carbon is separated from the mixed solution, washed with deionized water and dried, and the obtained black granular activated carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com