bags and products

一种制品、背面的技术,应用在容纳颗粒状可流动组合物的袋领域,能够解决成本升高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

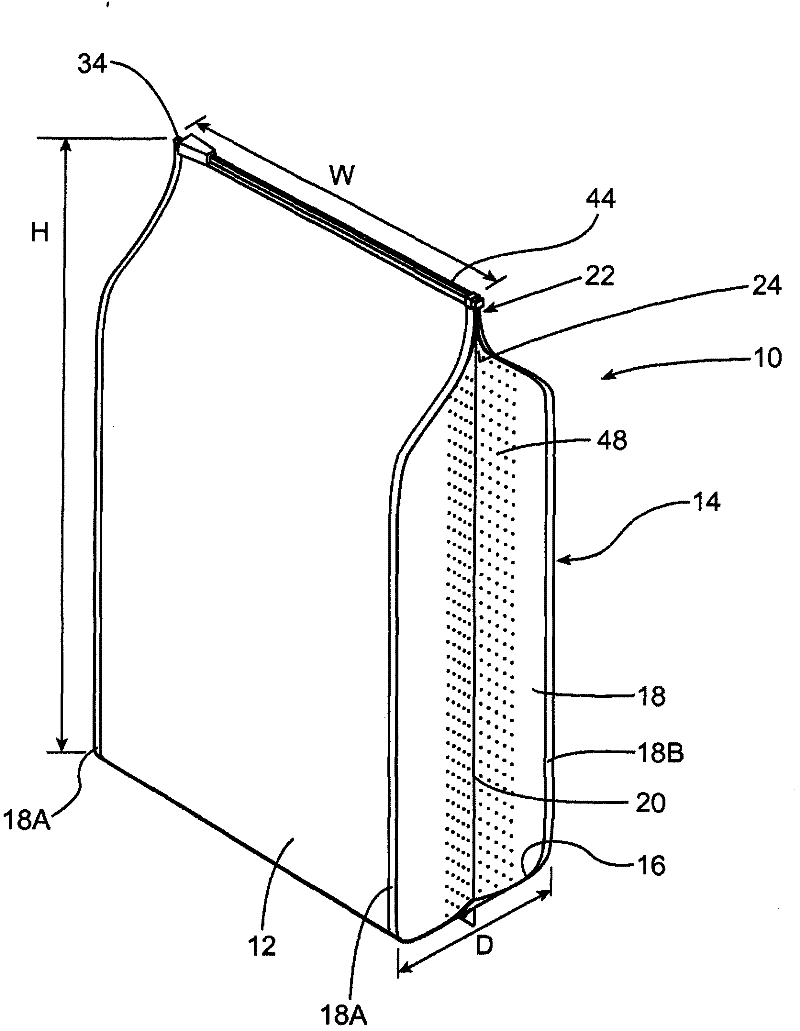

[0084] The bag of the present invention can be constructed as follows.

[0085] A plastic laminate film comprising a 12 micron thick layer of polyethylene terephthalate ("PET") bonded to a 140 micron thickness by adhesive lamination was used to form the pouch. Thick coextruded layers of metallocene linear low density polyethylene, medium density polyethylene and metallocene linear low density polyethylene (from eg Exopack, Spartanburg, SC, USA). Once the bag is formed, the coextruded polyethylene layer forms the inner surface of the bag and the PET layer forms the outer surface of the bag.

[0086] Gusset the sides of the bag. The two edges of each side gusset on each side of the bag are sealed to form two edge seals on each side resulting in a four edge (4) seal thus forming a "four side seal" bag. The bag is sealed at the bottom by conventional heat sealing, trapping the bottom of the side gussets therein and forming the bottom surface. The side gussets are also sealed at...

Embodiment 2

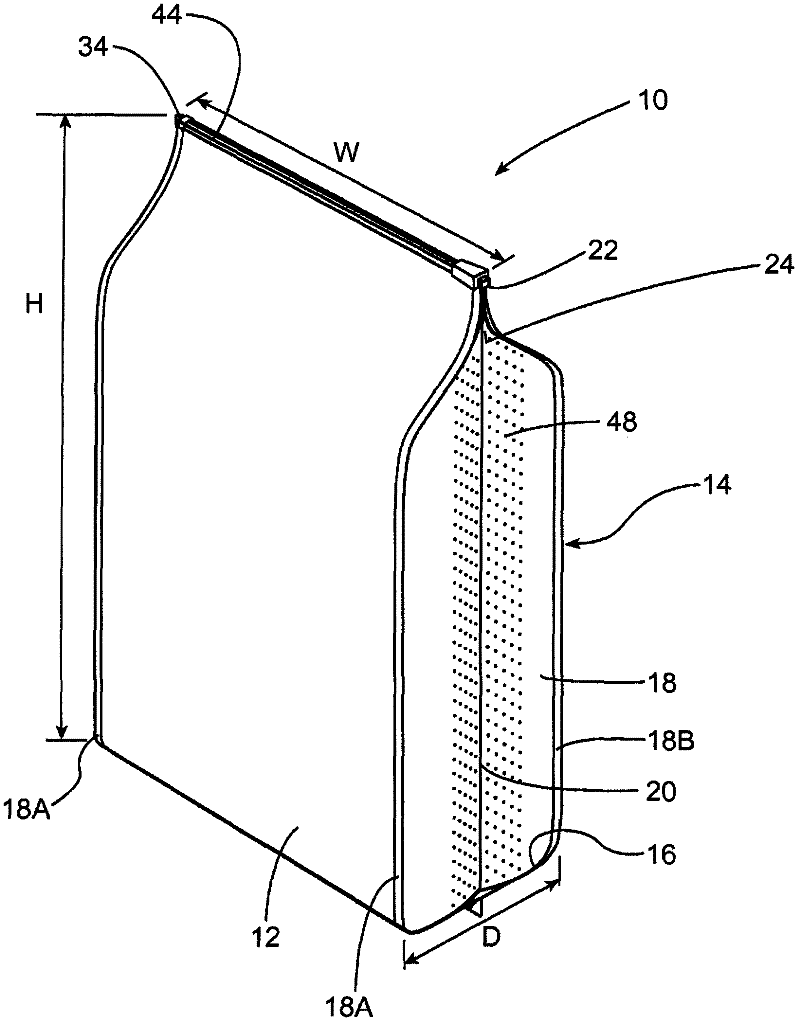

[0092] An alternative embodiment of the bag of the article of the present invention can be made as follows.

[0093] A plastic laminate film comprising a 12 micron thick layer of polyethylene terephthalate ("PET") bonded to a 165 micron thickness by adhesive lamination was used to form the pouch. Thick coextruded metallocene linear low density polyethylene, medium density polyethylene and metallocene linear low density polyethylene layers (from eg Exopack, Spartanburg, SC, USA) were on top. Once the bag is formed, the coextruded polyethylene layer forms the inner surface of the bag and the PET layer forms the outer surface of the bag.

[0094] Gusset the sides of the bag. The two edges of each side gusset on each side of the bag are sealed to form two edge seals on each side, resulting in four edge (4) seals, thus forming a "four side seal" bag. The bag is sealed at the bottom by a conventional heat seal, capturing the bottom of the side gussets and forming the bottom surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com