A method for evaluating the machining accuracy of building components

A technology for machining precision and building components, which is used in the field of detection and precision evaluation of objects with complex geometric shapes in space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

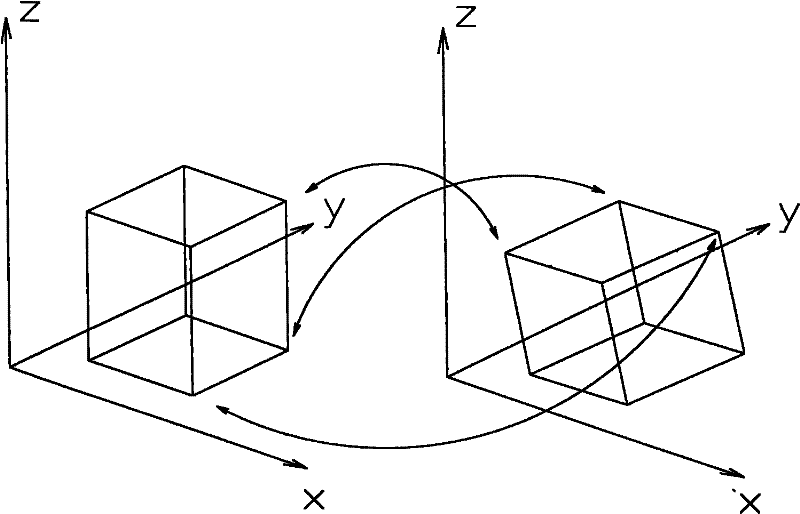

[0025] see figure 1 , 1 means selecting appropriate control points from the physical components and design documents, and collecting control data one by one. 2 means to classify the data in one-to-one correspondence and import them into the computer. 3 means to analyze the data as a whole and select the most reasonable coordinate conversion function. 4 means that the digital model of the physical component is transformed into the coordinate system made by the design model through the conversion function. 5 means that the machining accuracy of the solid component is obtained by analyzing the difference between each pair of control point data one by one.

[0026] see figure 2 , first of all, two sets of digital models of the physical component and component design need to be established respectively, and the selected control points need to correspond one-to-one. exist figure 1 Taking the box structure as an example, the corner points of the box can be selected as control p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com