Automatic blowdown valve

A technology of automatic sewage discharge and valve body, which is applied in the direction of valve details, control valves, valve devices, etc., can solve the problems of automatic sewage discharge, short service life of sewage valve, unreliable sealing, etc. reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

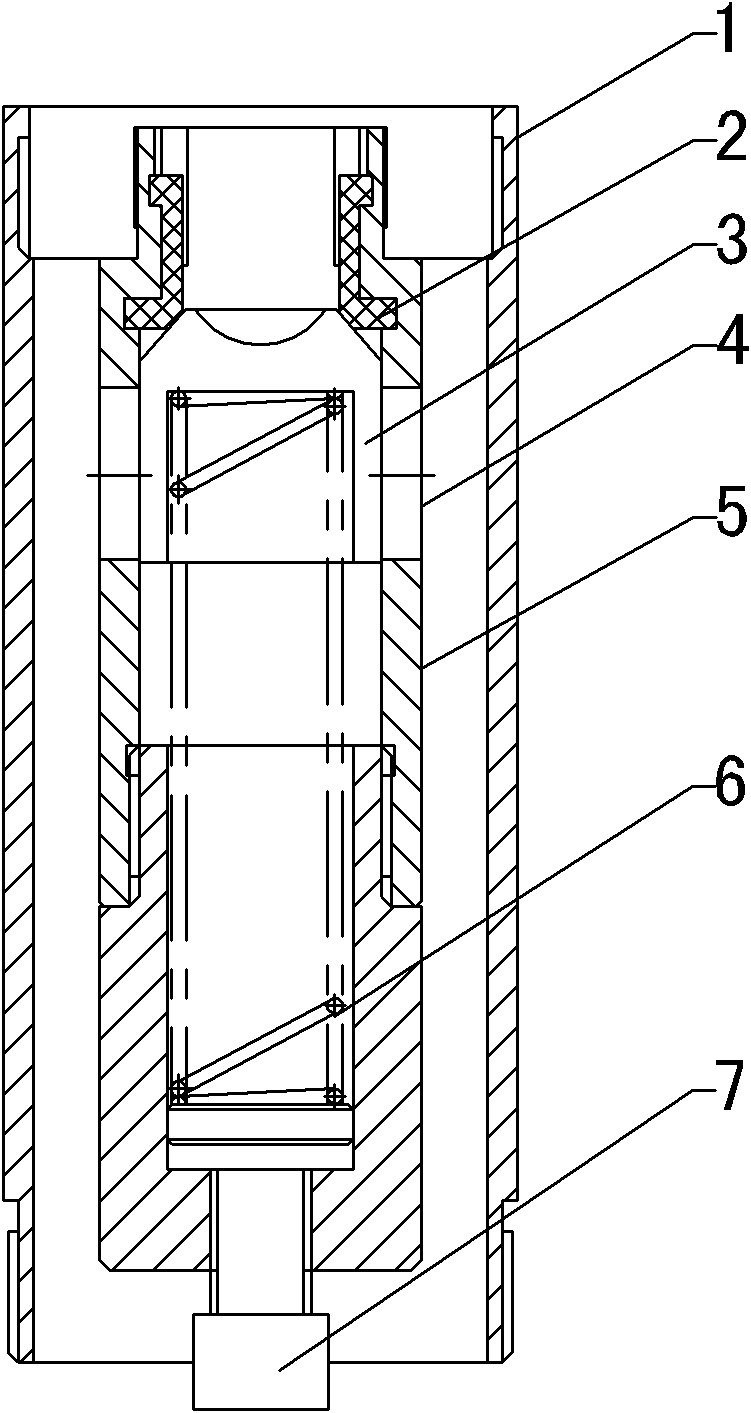

[0013] Refer to attached figure 1 :

[0014] The sewage valve includes a sheath 1, a valve core 3 and a valve body 5. The valve body 5 is divided into upper and lower parts, which are connected by threads. The upper part of the valve body 5 is equipped with a valve core 3. The rubber sealing ring 2, in order to protect the rubber sealing ring 2 from being damaged by the high-pressure liquid, the rubber sealing ring 2 is equipped with a metal bushing, and the upper part of the valve body 5 is evenly distributed with three drain holes 4 on the upper circle, and the valve at the bottom of the valve core 3 The body 5 is equipped with a spring 6, the bottom of the valve core 5 is provided with a screw hole, and the screw hole is equipped with an adjusting screw 7 for adjusting the pressure of the spring 6 to fix the spring 6 and ensure the stability of the spring 6. The valve body 5 is covered with an upper , The sheath 1 with internal thread at the lower end is used to screw into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com