A kind of coproduction method of citrus peel essential oil and pectin

A technology for citrus peel and pectin, which is applied in the field of agricultural and sideline products processing, can solve the problems of reduced economic value of citrus peel processing and utilization, unsuitable citrus peel, environmental pollution, etc., and achieves remarkable economic and social benefits, simple procedures, and reduced environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

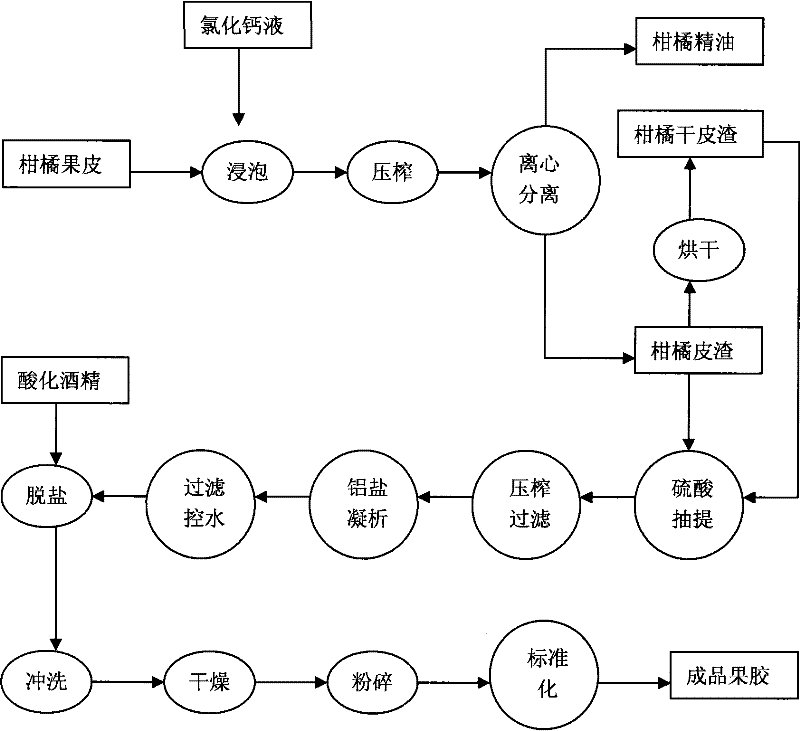

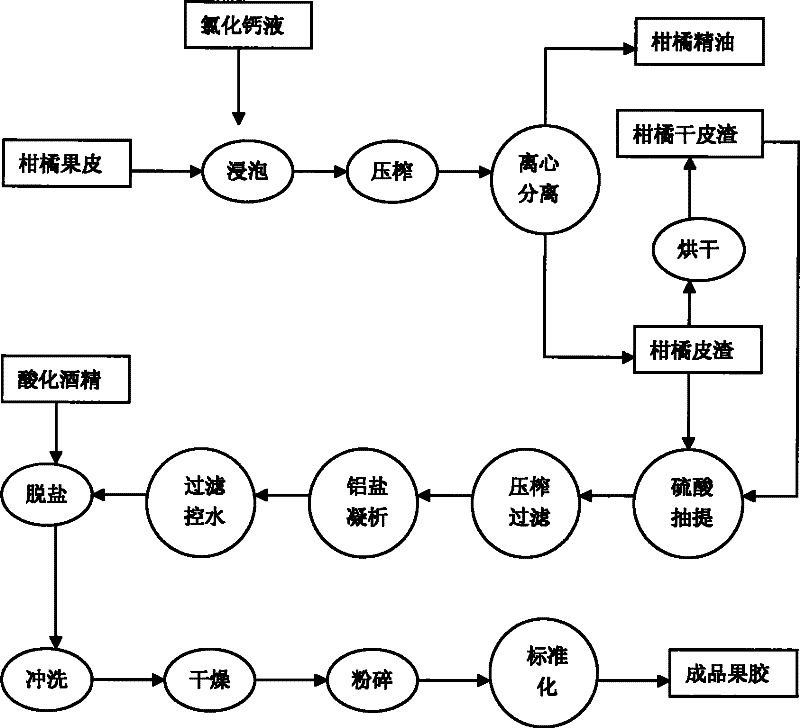

[0026] The invention relates to a co-production method of citrus peel essential oil and pectin, such as figure 1 As shown, it is characterized in that the canned orange peel is soaked in the mixed hardening solution containing 0.5%-1.2% of calcium chloride, and the orange peel is soaked in the hardening solution for more than 12 hours and squeezed by a roller press to obtain orange peel. Mixture of peel residue, orange oil and water, send the orange peel residue to the extraction barrel to adjust the pH value to 2-2.5 with sulfuric acid, cook at 95°C for 42-48 minutes, then extract, separate, salt out, filter, and desalt , cleaning, drying and crushing to obtain pectin; the mixture of orange oil and water is filtered, centrifuged, precipitated, stored at low temperature and filtered again to obtain citrus peel essential oil, and the same orange peel raw material used to process canned citrus cans is used to realize co-production of citrus peel Essential oils and pectins. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com