An industrial tail gas energy conversion system

An industrial exhaust, energy-based technology, applied in the petroleum industry, through chemical separation, air quality improvement and other directions, can solve problems such as low efficiency and lack of reducing power, and achieve the effect of solving discontinuous supply and important use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

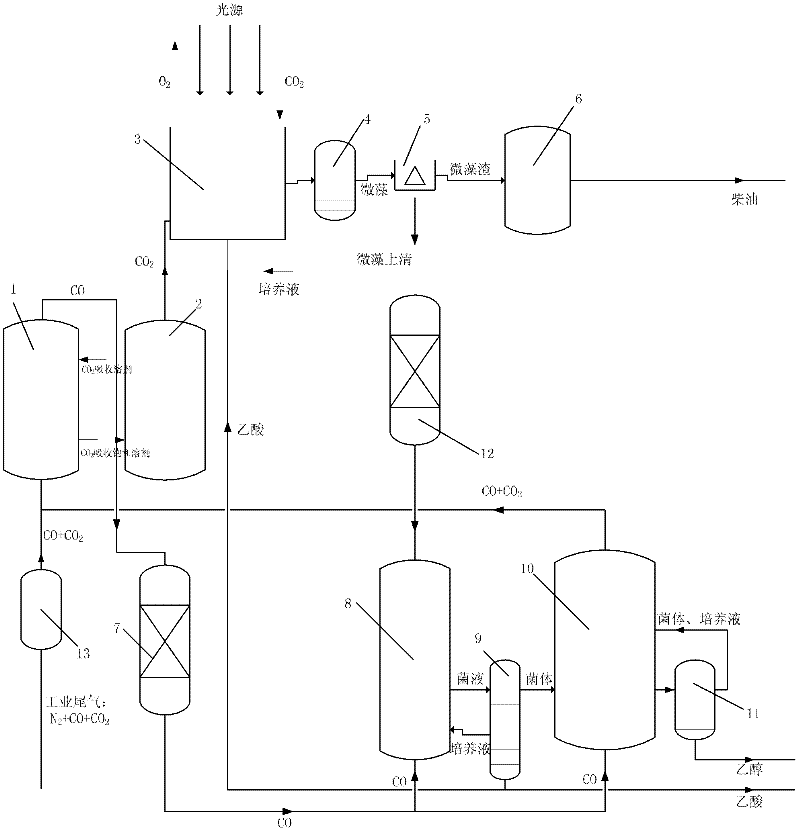

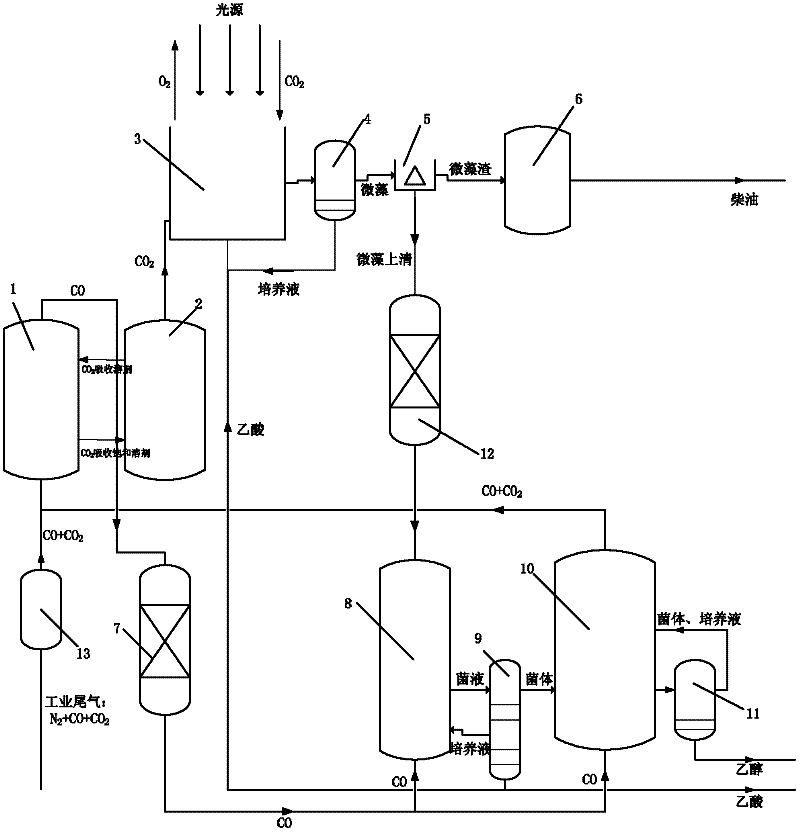

[0037] The industrial tail gas energy conversion system of this embodiment includes CO 2 Absorber 1, CO 2 Absorber 1 and N 2 Separation device 13, CO 2 The separation device 2 is connected to the first deoxygenation column 7, and the first deoxygenation column 7 is also connected to the growth tank 8 of the synthesis gas fermentation strain and the fermentation tank 10 of the synthesis gas fermentation strain respectively, and the CO 2 Separation device 2 is connected with microalgae cultivation device 3, microalgae and microalgae culture liquid separation device 4, microalgae separation device 5, microalgae extraction diesel oil reactor 6 and diesel oil output pipeline, microalgae cultivation device 3 and microalgae and microalgae and The microalgae culture solution separation device 4 is also connected with a microalgae culture solution return pipeline, the microalgae separation device 5 and the second deoxygenation column 12, the synthesis gas fermentation strain growth t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com