Connector and method of making the same

A manufacturing method and connector technology, which are applied in the direction of connection, contact parts, circuit/collector parts, etc., can solve the problems of shrinking, disappearing, and high gold consumption of solder balls 160, so as to avoid solder climbing, reduce production costs, The effect of reducing the amount of gold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

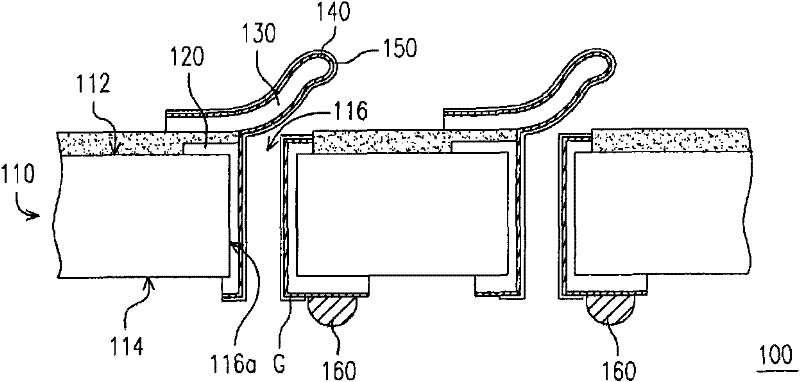

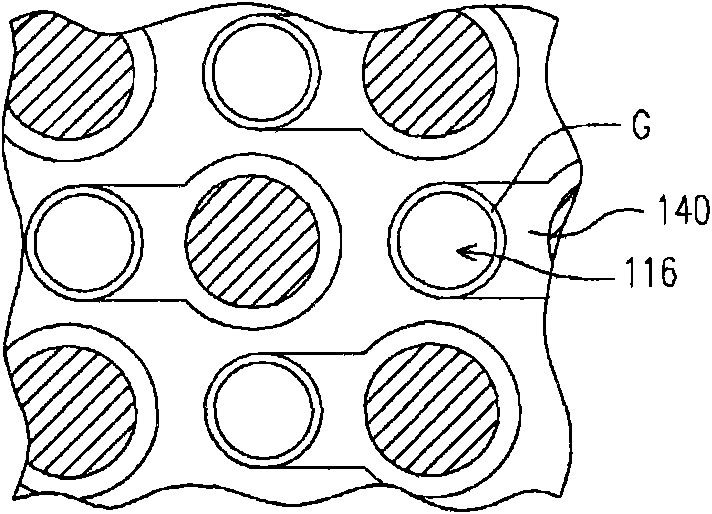

[0055] Figure 2A ~ Figure 2K A cross-sectional view of the manufacturing process of the connector according to an embodiment of the present invention is shown. Figure 3A A sectional view illustrating a connector according to an embodiment of the present invention, Figure 3B draw Figure 3A The bottom view of the connector.

[0056] First, please refer to Figure 2A , provide a substrate 210, the substrate 210 has a first surface 212 and a second surface 214 opposite, wherein the substrate 210 is, for example, a double-sided board (a plate with a conductive layer on both sides of a single dielectric layer), a single-sided board ( A single dielectric layer has a conductive layer on one side), a single dielectric layer or a multi-layer board (multiple dielectric layers and multiple conductive layers stacked alternately).

[0057] In this embodiment, the substrate 210 is a double-sided board, and the substrate 210 includes a dielectric layer I and two conductive layers C1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com