Method for manufacturing anodic aluminum oxide template and method for manufacturing field emission cathode array material by using template

A technology of anodic aluminum and field emission cathode, which is applied in anodizing, cold cathode manufacturing, electrode system manufacturing, etc., can solve the problems of rationality limitation of preparation process, good field emission cathode array, and no preparation performance, etc. The effect of area start-up voltage, simple hole arrangement, and clean surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

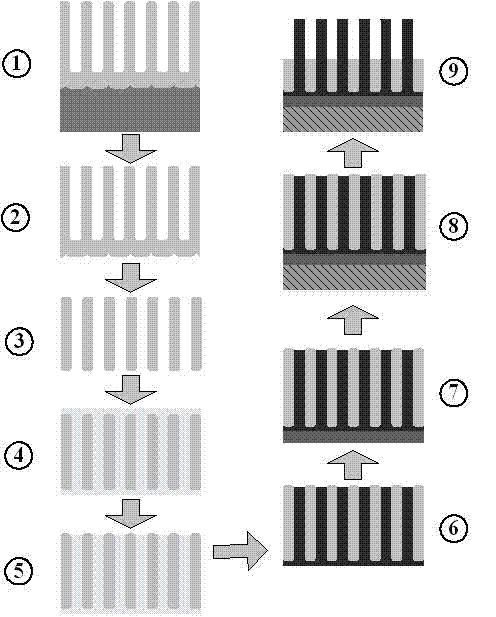

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings.

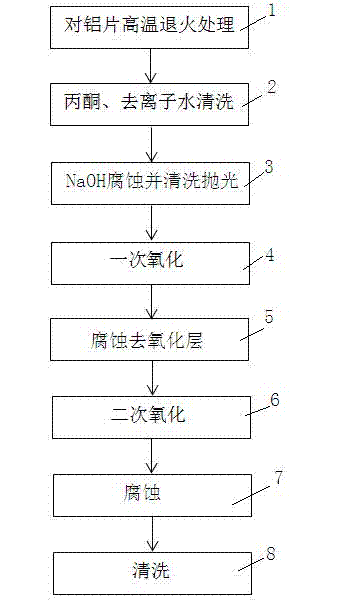

[0053] See figure 1 , to prepare a large-area anodized aluminum template with regular shape and clean surface. The specific process is as follows:

[0054] (1) Anneal the high-purity aluminum sheet at 500°C for 4 hours under nitrogen protection.

[0055] (2) The annealed aluminum sheet was ultrasonically cleaned with acetone and pure water respectively.

[0056] (3) Coat the back with organic matter protection first, dry and corrode in 5% NaOH solution for 8 minutes to remove the oxide layer, then rinse with water, and use perchloric acid ethanol solution (perchloric acid: ethanol solution = 1: 4 (volume ratio)) electrochemical polishing. The distance between the plates is 8cm; the current: 200mA, clamped on the rubber pad, the rubber strip is required to be half submerged below the polishing liquid surface, and the electropolishing time is 10min.

[0057] (4) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com