Lock core of axially-offset magnetic control steel column

A steel column and offset technology, applied in the field of locks, can solve the problems of inability to lock or open normally, poor reliability of the lock cylinder, and high requirements on machining accuracy, and achieve the effects of reliable digital management, prevention of theft and loss, and low application cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

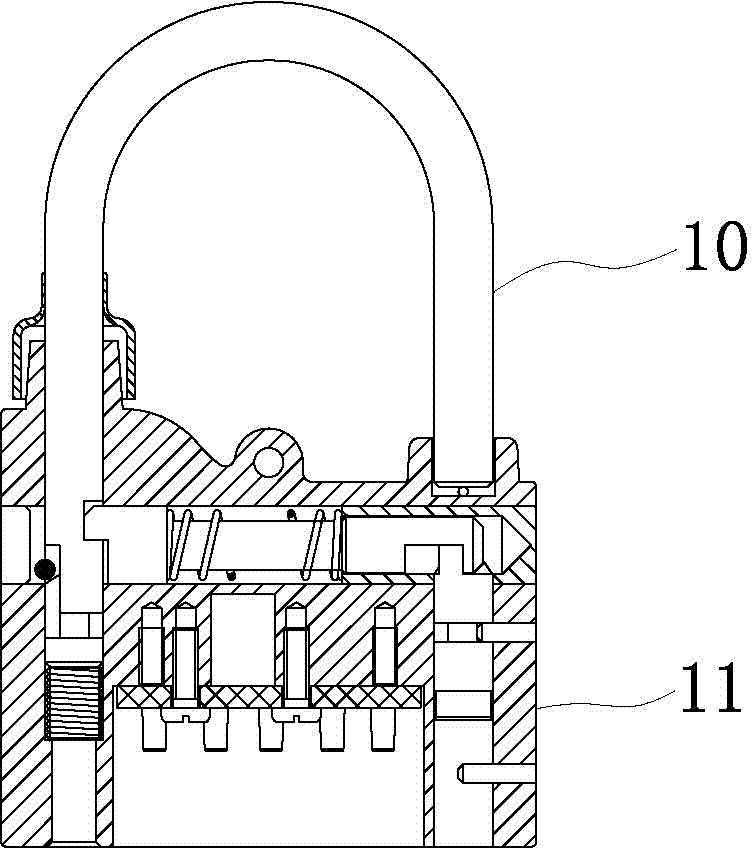

Image

Examples

Embodiment Construction

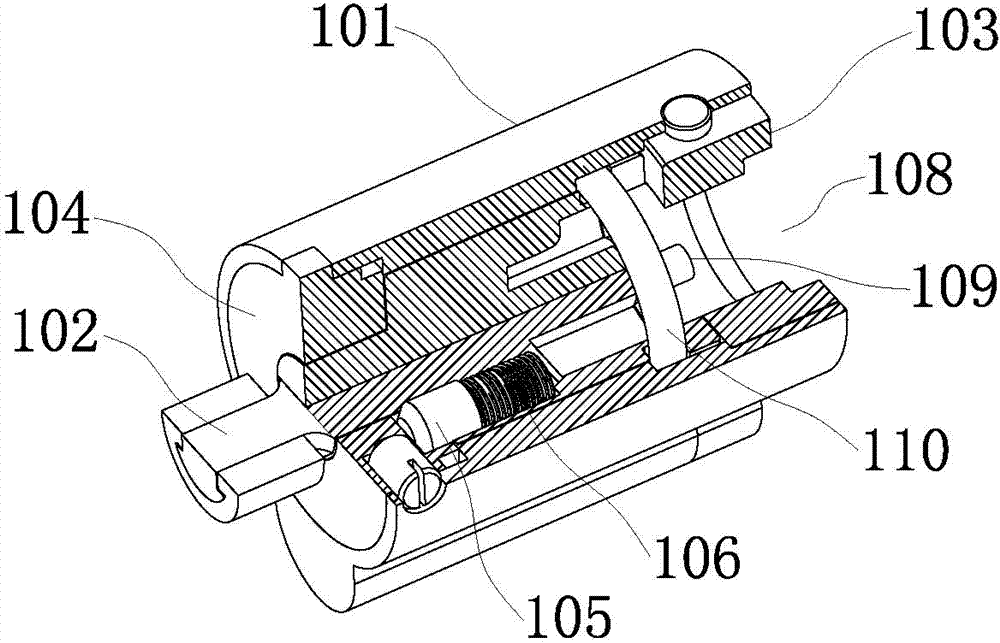

[0019] see image 3 , is a schematic cross-sectional view of a lock core of an axially biased magnetron steel column in a locked state according to the present invention.

[0020] The lock cylinder includes a core sleeve 101 , a mandrel 102 , front end caps 103 and rear end caps 104 arranged at both ends of the core sleeve 101 , steel column pins 105 and pin springs 106 for locking and positioning. The mandrel 102 and the rear end cover 104 are respectively provided with at least one corresponding pin hole 107 (please refer to Figure 4 ), in this specific implementation manner, a set of corresponding pinholes 107 is taken as an example to describe in detail.

[0021] The axis of the pin hole 107 is parallel to the axis of the mandrel 102 ; the steel column pin 105 and the pin spring 106 are disposed in the pin hole 107 . The end of the core sleeve 101 provided with the front end cover 103 is provided with an unlocking lever compartment 108 for placing an unlocking lever (no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com