Automatic spraying equipment

A spraying equipment and fully automatic technology, applied in the direction of coating, spraying device, and device for coating liquid on the surface, etc., can solve the problems of increased production cost, large production space, uneven spraying, etc., and achieve production cost saving and high level The effect of space reduction and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

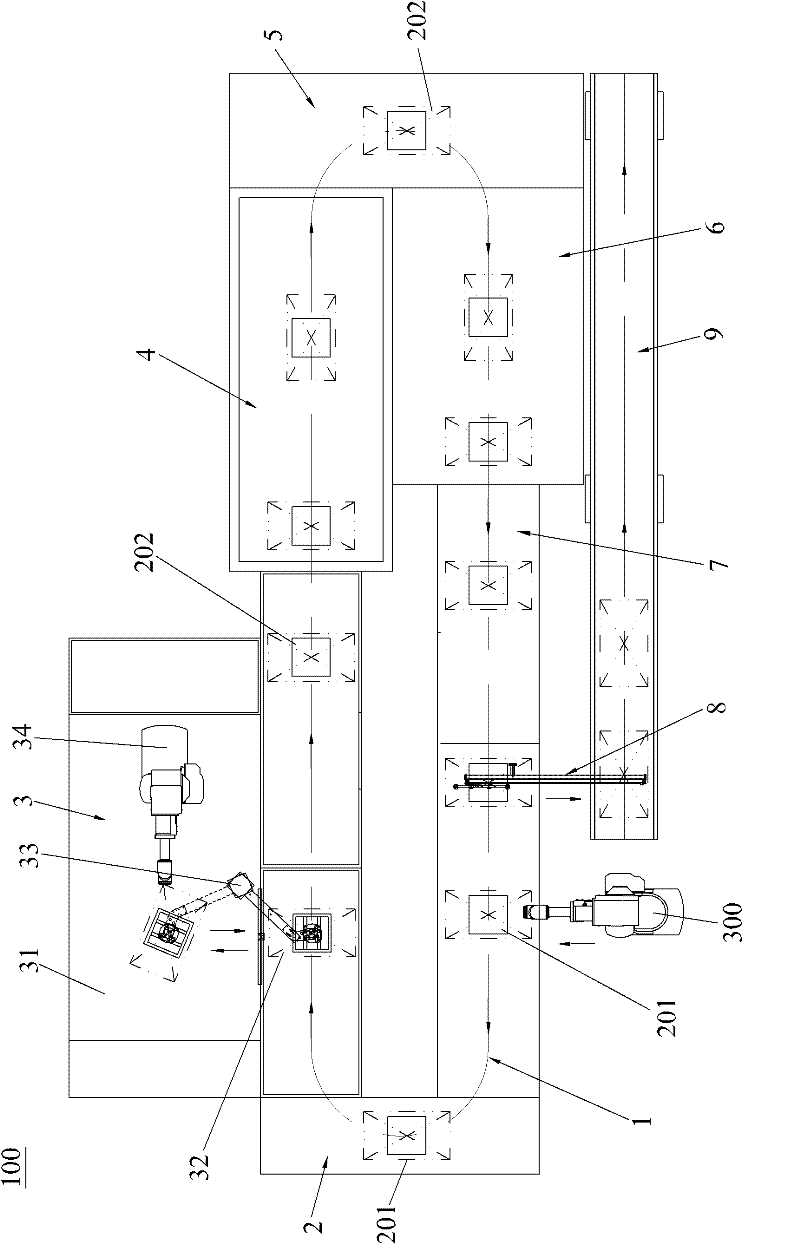

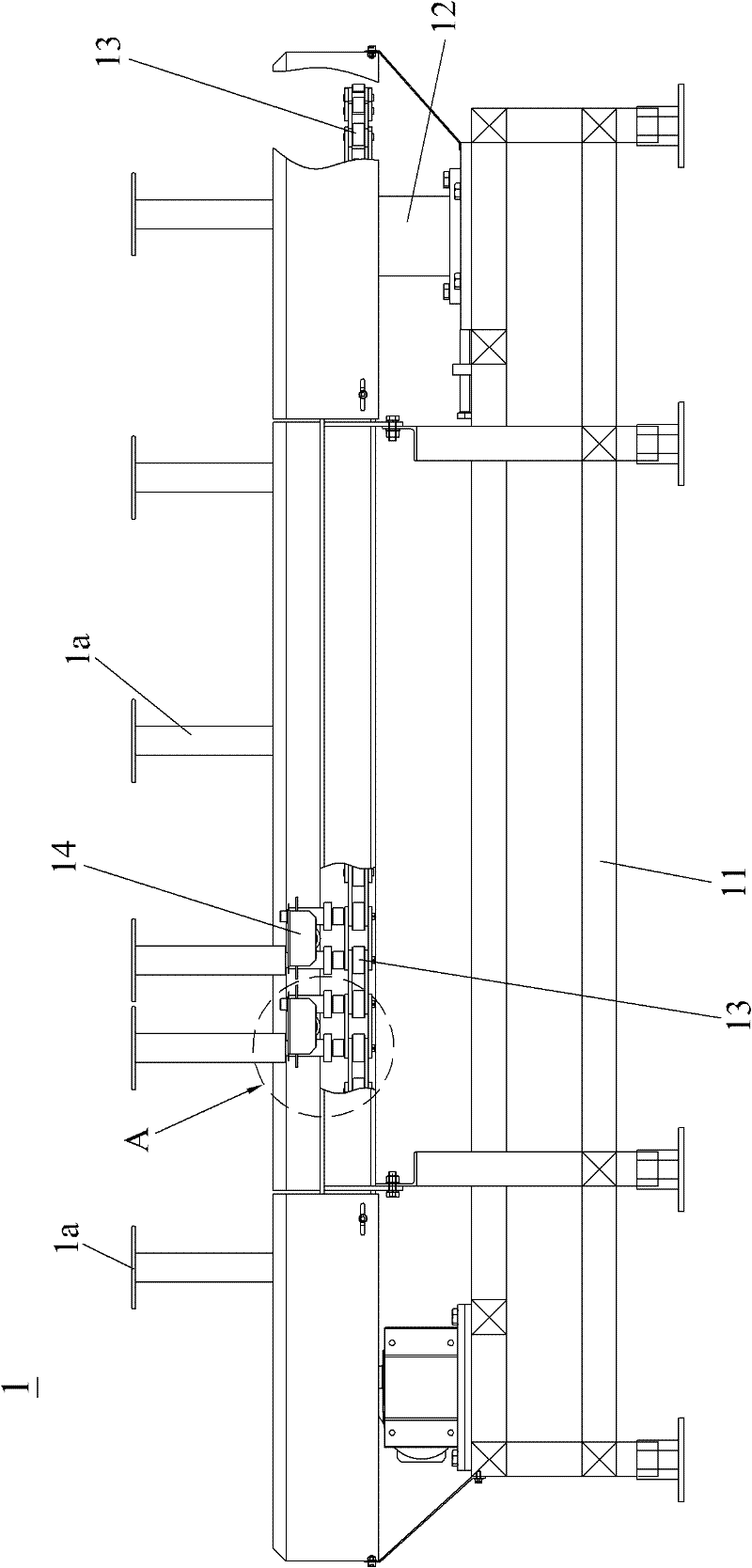

[0029] Such as figure 1 and figure 2 As shown, the automatic spraying equipment 100 of the present invention includes a ground rail conveyor chain 1, cooling and dust removal equipment 2, a spraying system 3, an infrared curing furnace 4, a cooling furnace 5, an ultraviolet curing furnace 6, a cooling zone 7, and an automatic unloading manipulator 8 , automatic conveyor belt 9, air supply and exhaust system 10 and control system (not shown in the figure).

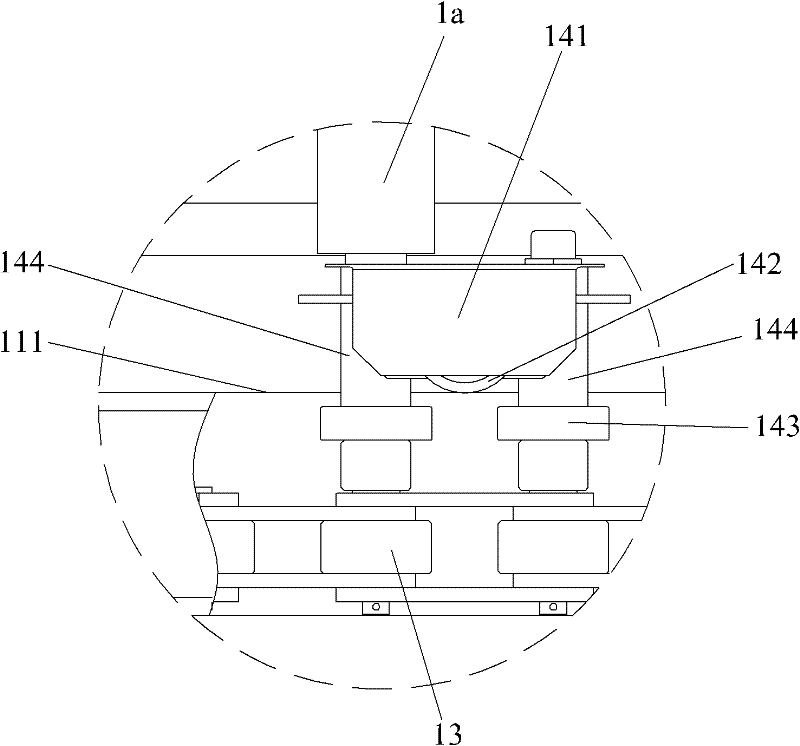

[0030] The ground rail type conveyor chain 1 includes a workpiece fixture 1a, and the workpiece fixture 1a carries a workpiece 201. The ground rail type conveyor chain 1 detours in a waist-shaped circuit and conveys the workpiece in a closed loop; the cooling and dust removal The equipment 2 is installed on the ground rail conveyor chain 1 to cool the workpiece 201 and remove the dust on the surface of the workpiece; the spraying system 3 includes a spray booth 31, a jacking and rotating device 32, a cantilever transfer m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com