Robust filtering and prediction using switching models for machine condition monitoring

一种机器、卡尔曼滤波器的技术,应用在仪器、通用控制系统、电气测试/监控等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

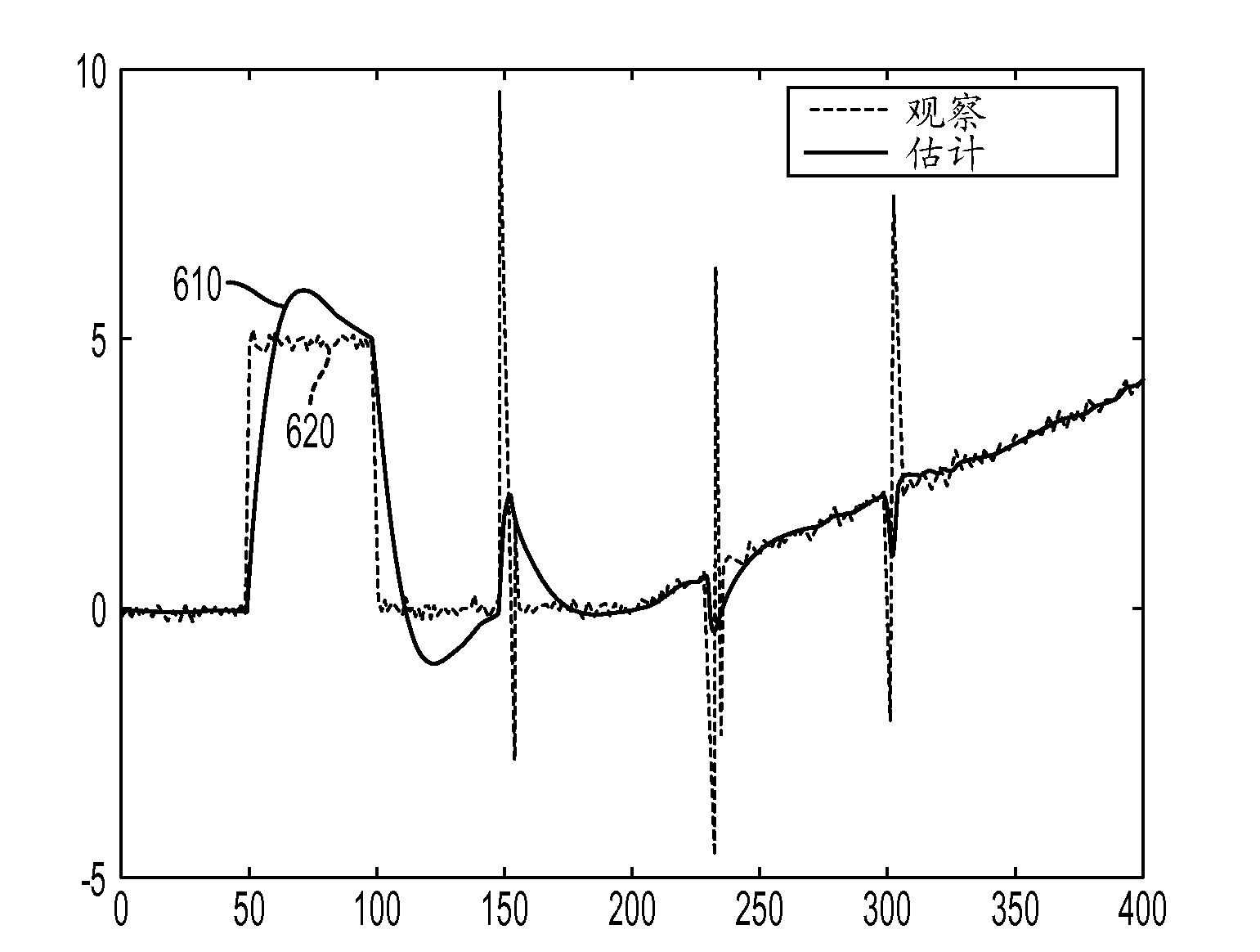

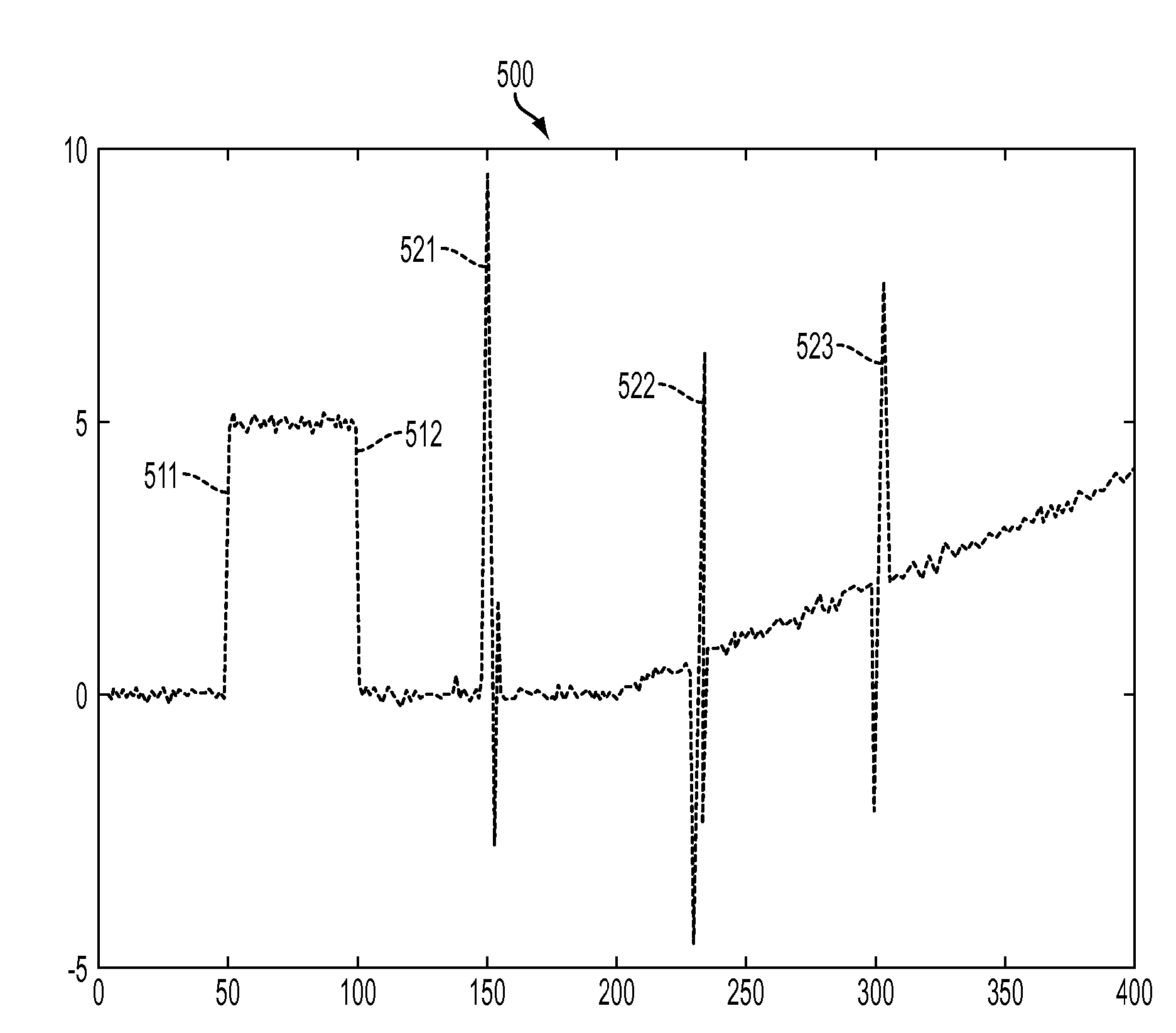

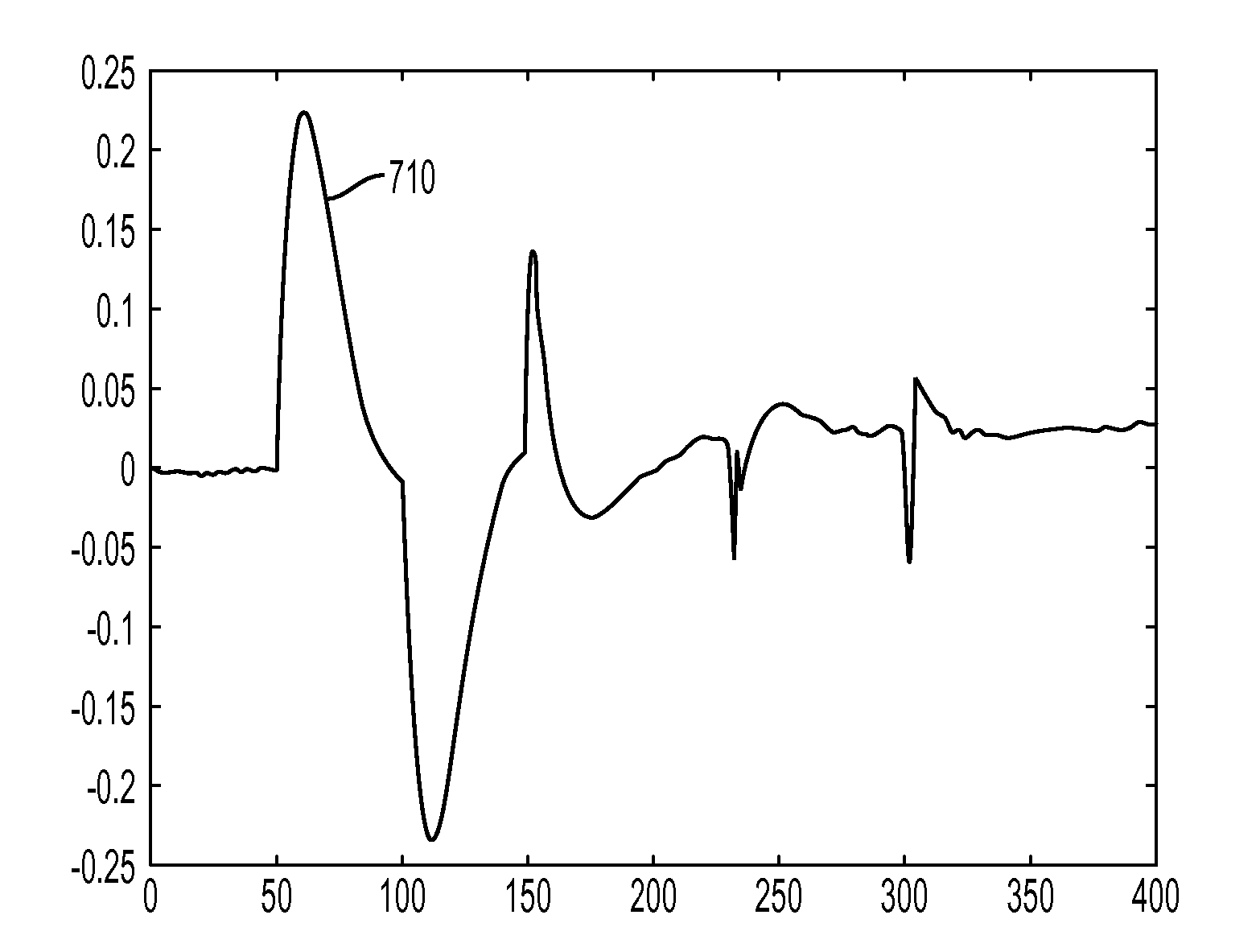

[0039] The invention may be embodied in a system for filtering sensor values, which system may be included in a machine monitoring system, or may be a stand-alone system. figure 1 A machine monitoring system 100 according to an exemplary embodiment of the present invention is illustrated. Such as figure 1 As shown, system 100 includes a personal or other computer 110 . Computer 110 may be connected to sensor 171 through wired or wireless network 105 . The system preferably includes additional sensors (not shown) that are likewise connected.

[0040] The sensors 171 are arranged to acquire data representative of characteristics of the machine or system 180 or the environment of the machine. The sensor measures characteristics such as temperature, pressure, humidity, rotational or linear speed, vibration, force, strain, power, voltage, current, resistance, flow rate, proximity, chemical concentration, or any other characteristic. As described above, the sensor 171 measures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com