Thimble cap of die bonder

A chip loader and thimble technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as normal chip absorption, dicing film gaps, and failure to lock the dicing film to reduce cracks. Or the risk of micro-cracks, the height of the ejector pin is reduced, and the effect of vacuum adsorption is firm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0020] The invention provides an thimble cap of a chip loading machine.

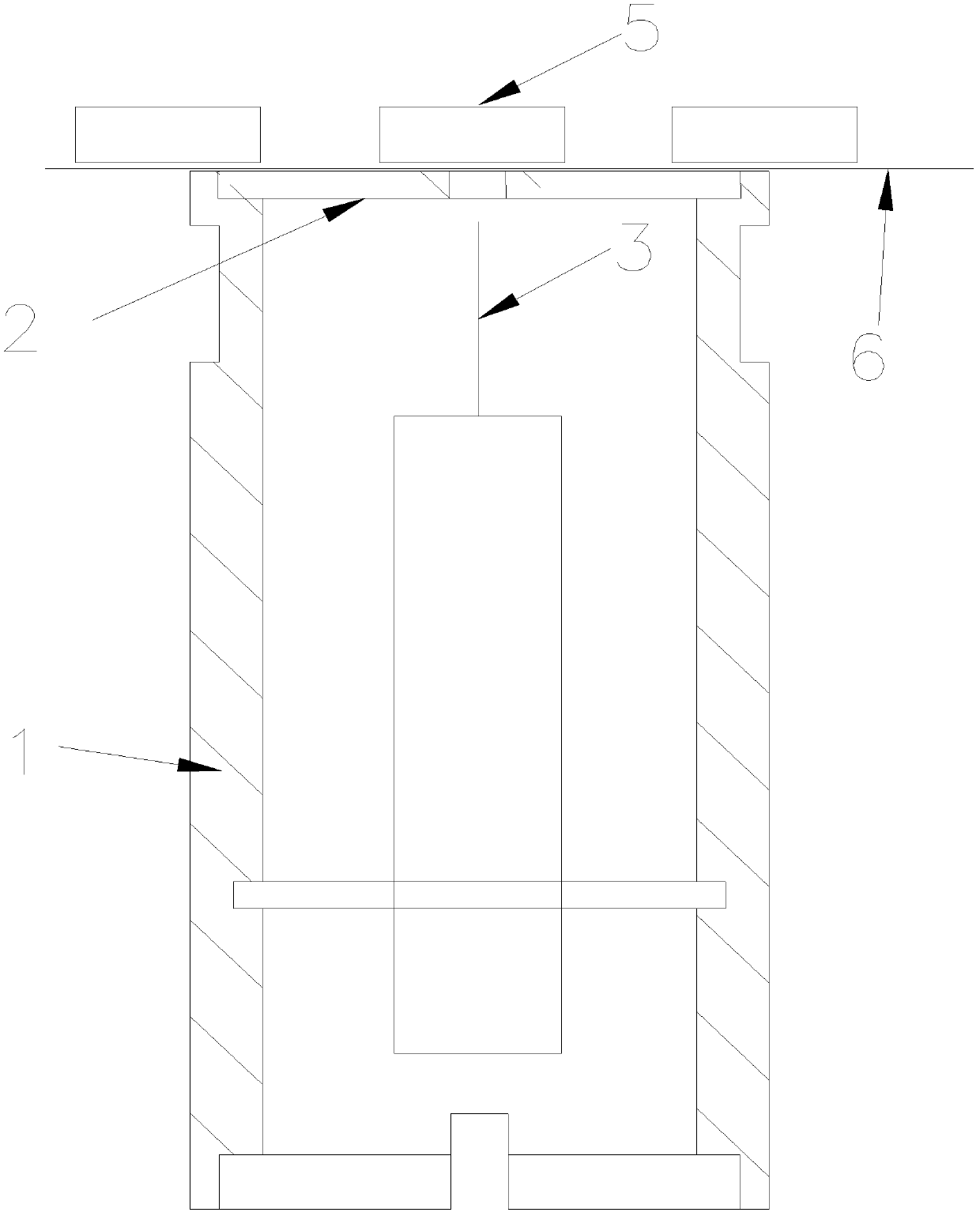

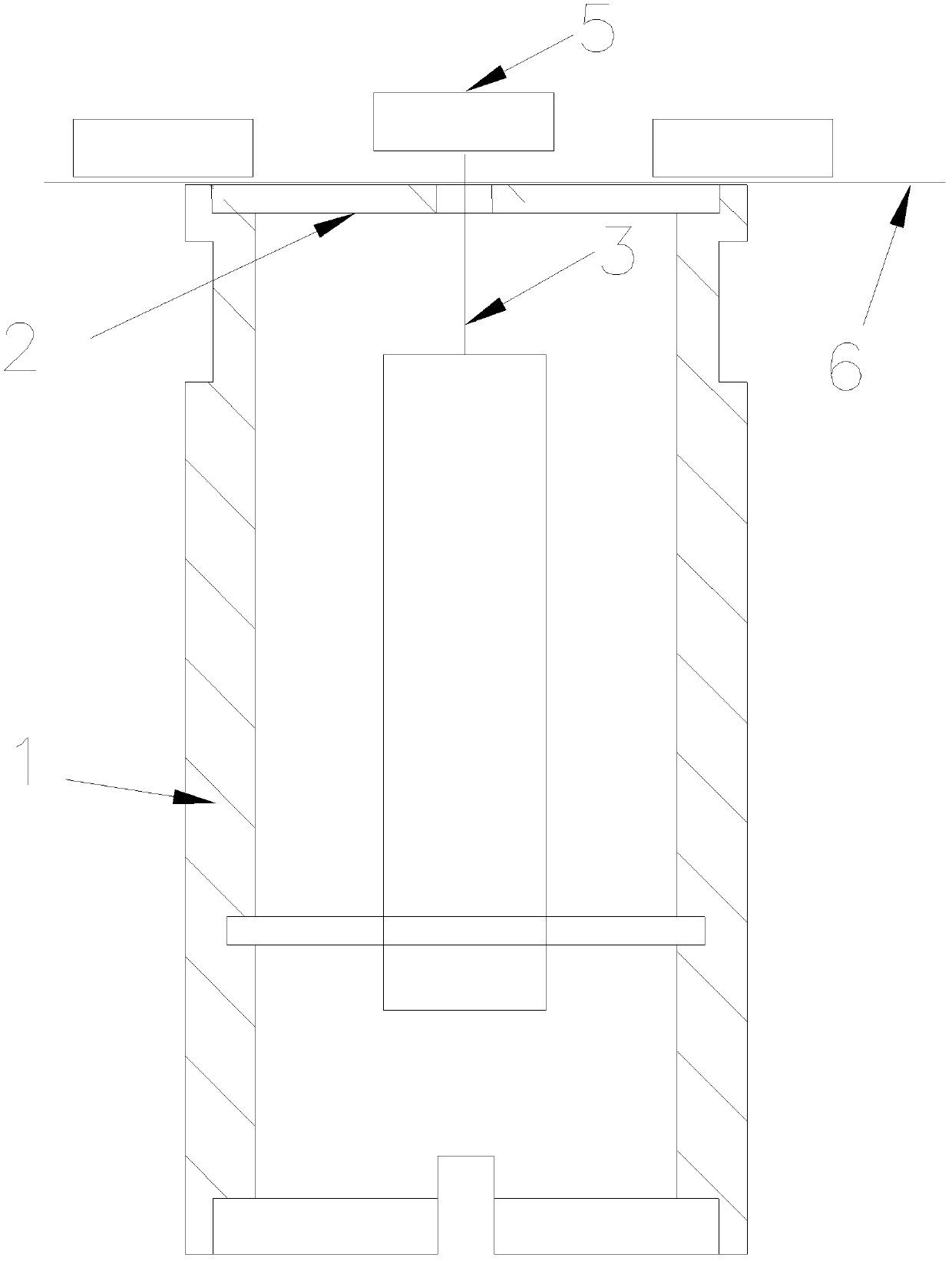

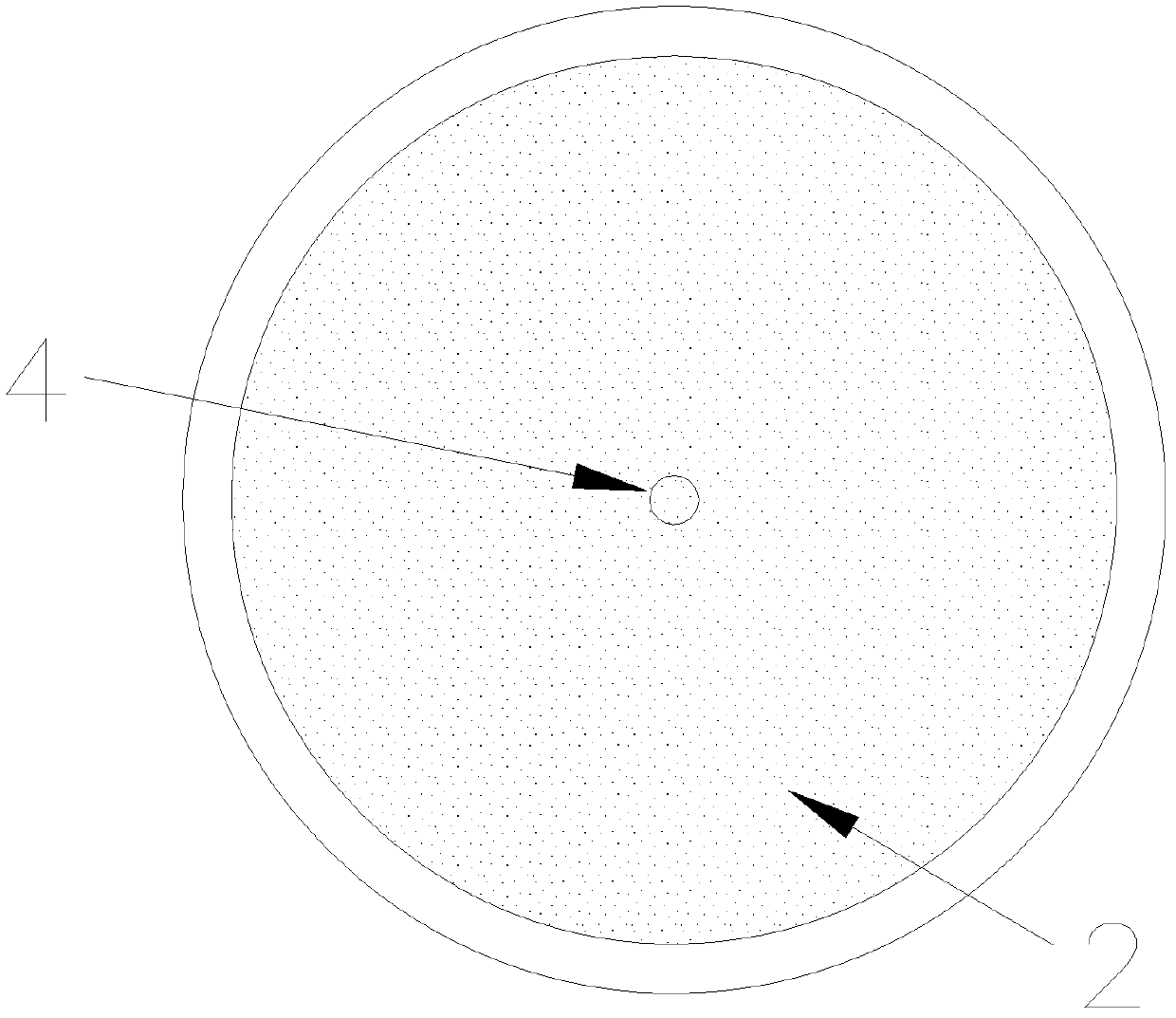

[0021] Such as Figure 1 to Figure 3 Shown: a thimble cap of a film loading machine according to an embodiment of the present invention, including a cap body 1, a cap 2, and an thimble 3 disposed inside the cap body 1, and the cap 2 is made of a porous material.

[0022] As a preferred embodiment of the present invention, the porous material may be, for example, a porous ceramic material, a porous metal material, or the like. The surface of the porous material is smooth, and there are many fine holes distributed inside the material. When the dicing film 6 is attached to the surface of the present invention, the vacuum inside the thimble cap passes through the numerous micropores of the porous ceramic material, and the dicing film 6 Adsorbed on the surface of cap 2.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com