Situation training module and method for lean production line

A technology for training modules and production lines, applied in teaching models, educational appliances, instruments, etc., can solve problems such as failure to achieve management skills training effects, and achieve the effects of reducing production costs, improving efficiency, and eliminating waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

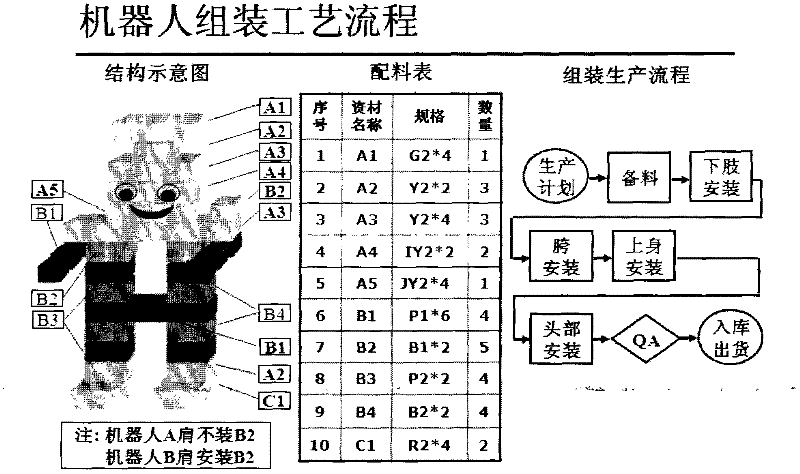

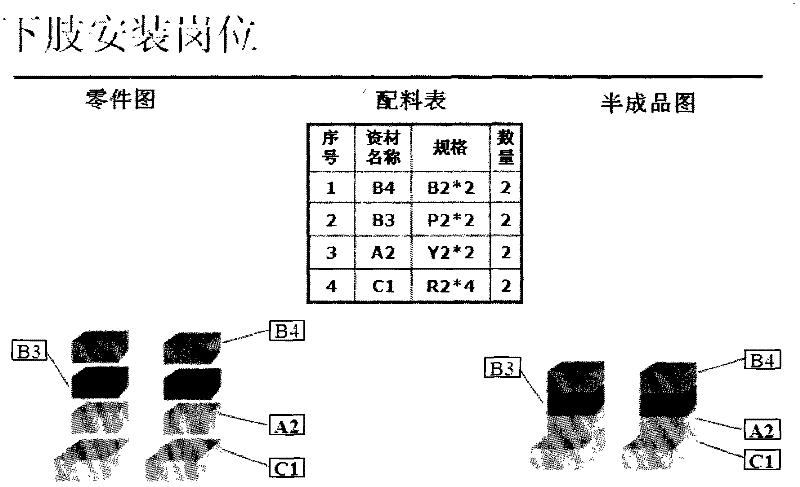

[0038] see figure 1 , the lean production line scenario training module and method is to simulate the actual production line through the scenario training module, and compare the training group to continuously discover the existing waste points and solve them.

[0039] The lean production line scenario training method completed by the above-mentioned building block model toy includes the following steps:

[0040] (1) Form a team

[0041] Select 1 person as the customer representative to place the order, select 1 person as the production planning specialist, correspond to the customer and internally issue the production plan, select 1 person as the raw material warehouse manager to issue materials, select 1 process engineer to be in charge of the process, and select 1 quality inspector to be in charge Warehousing quality inspection; select one team leader for each production line, and each team assigns several team members to be appointed by the team leader;

[0042] (2) Rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com