Large-scale grouping optimizing method of parts based on feed characteristic

An optimization method and large-scale technology, applied in special data processing applications, system integration technology, instruments, etc., can solve the problems of high dependence of clustering algorithm of grouping results, unsatisfactory stability of grouping results of adaptability to part data changes, etc. Optimizing the effect of improving utilization and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

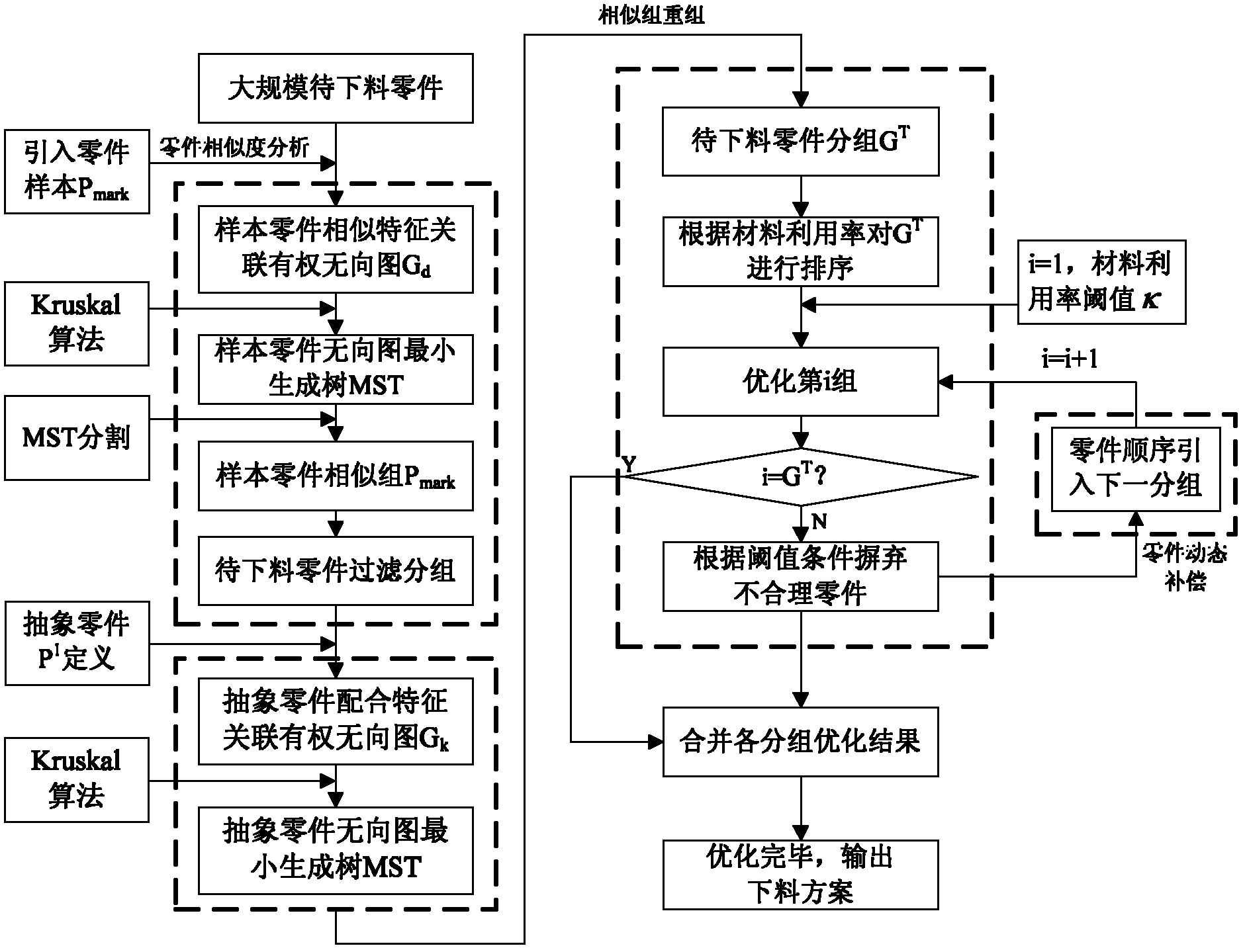

[0042] In order to solve the problem of large-scale part blanking, the research is carried out from the perspective of part grouping optimization. The present invention provides a large-scale part grouping optimization method based on the characteristics of blanking. By ideally splitting the large-scale part blanking problem, the The contradiction between the algorithm's time efficiency and material utilization is solved.

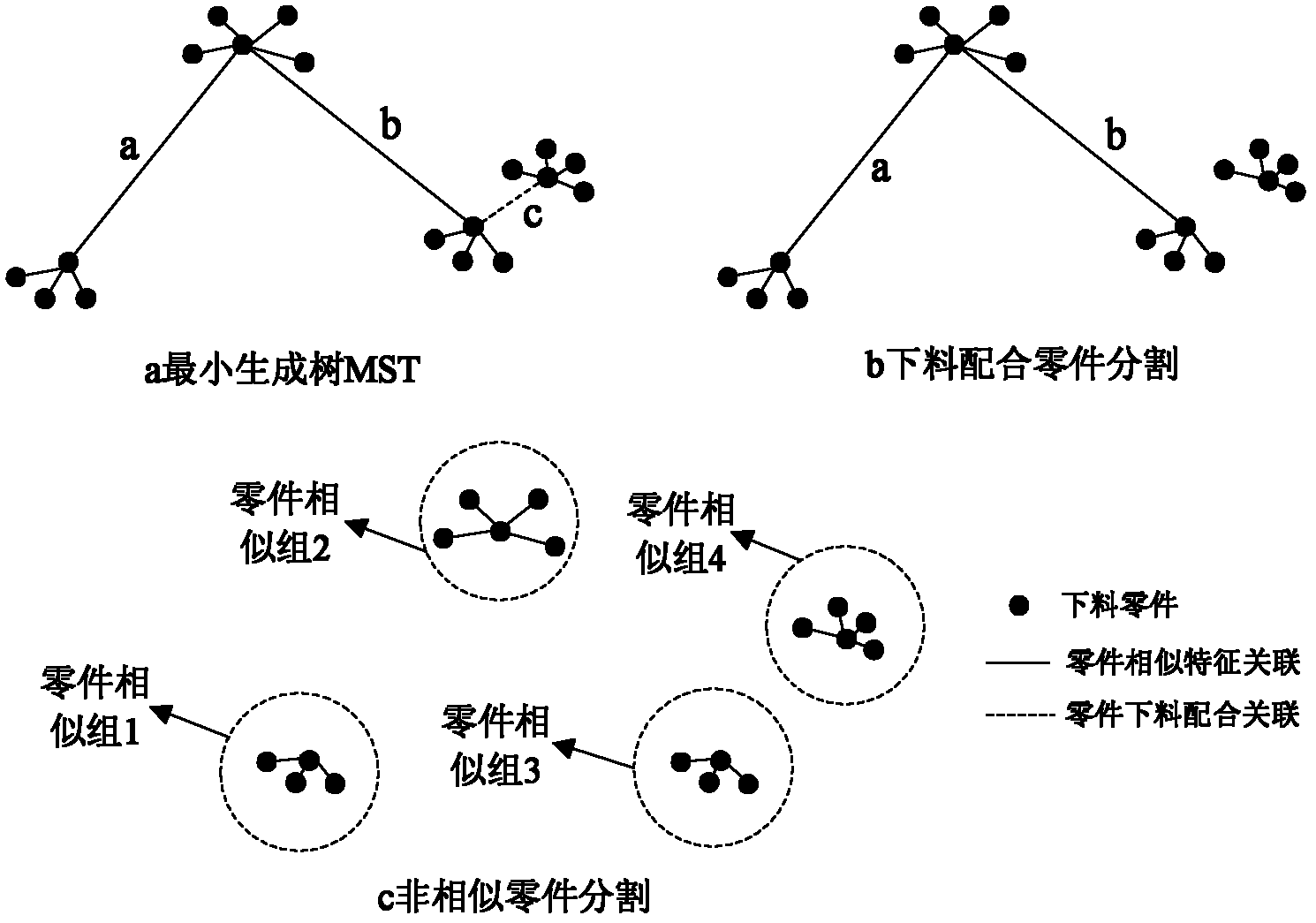

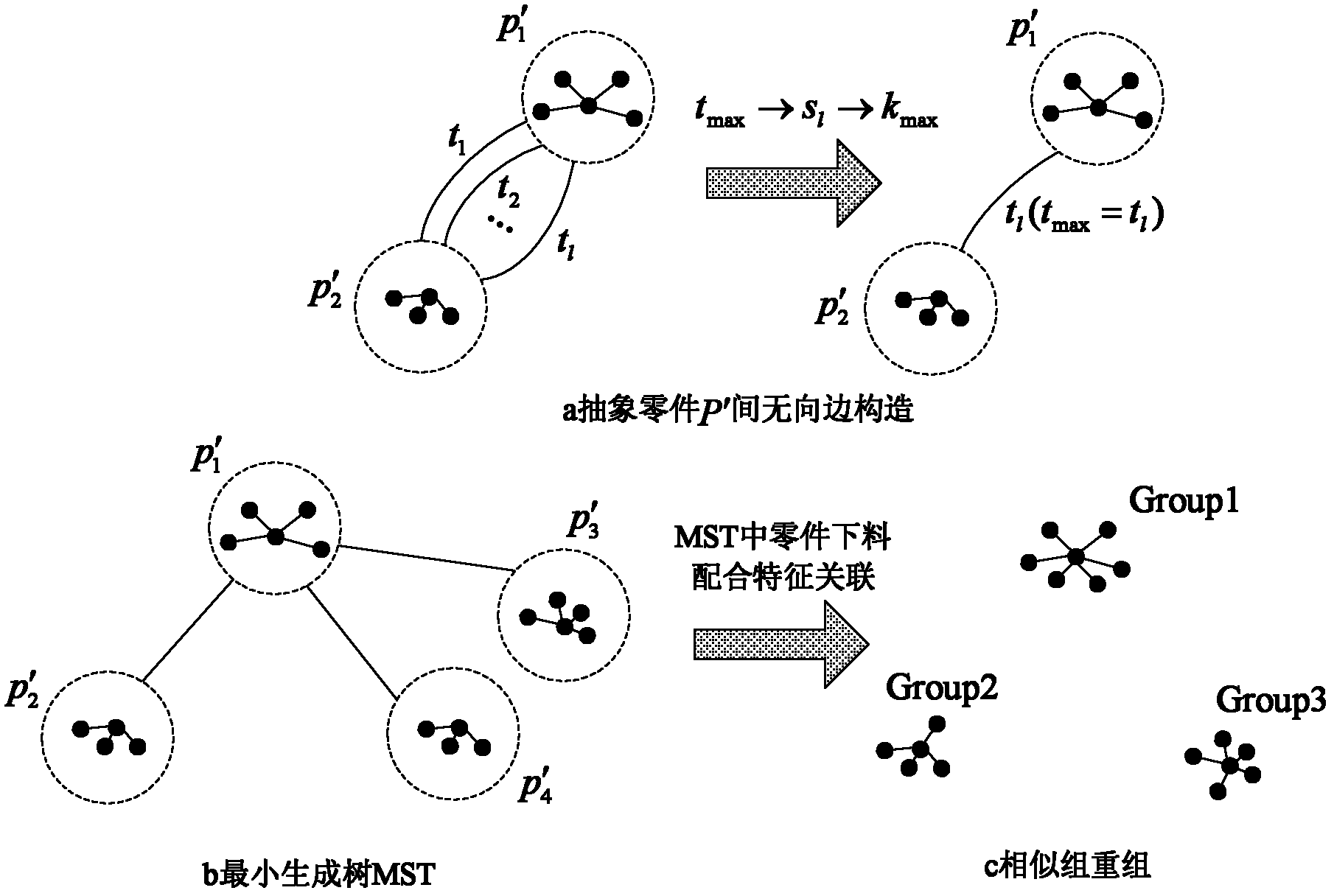

[0043] The essence of optimal blanking is to fill the raw materials to the greatest extent based on the combination of parts. Grasping the key blanking characteristics of parts is the focus of exploring a reasonable grouping method. The similarity characteristics of parts and the matching characteristics of blanking materials are the two most important types of blanking. Features, part similarity feature refers to the similar characteristics of parts in appearance, and part blanking matching feature refers to the combination relationship established when par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com