Parameterization design method and system based on assembly assembling

A parametric design and parametric technology, applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problems of uninvolved or disclosed assembly methods and management, and achieve the goal of improving product design efficiency and saving design time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

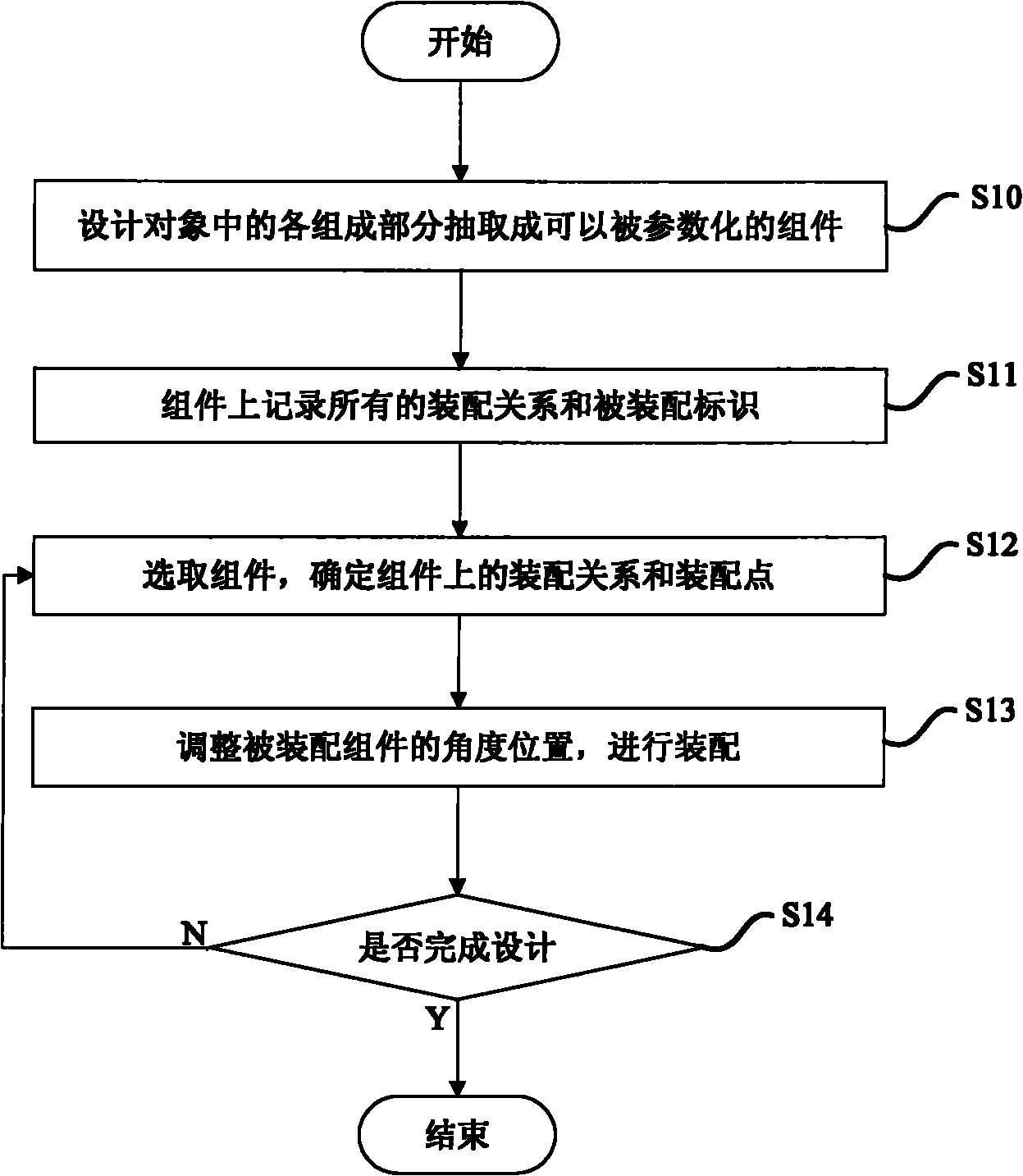

[0045] Such as figure 1 As shown, a parametric design method based on component assembly includes the following steps:

[0046] S10, extracting various components in the design object into components that can be parameterized;

[0047] In this embodiment, the component that can be parameterized is an independent entity, and this individual may be a basic component, or a component that is engaged with each other by multiple basic components.

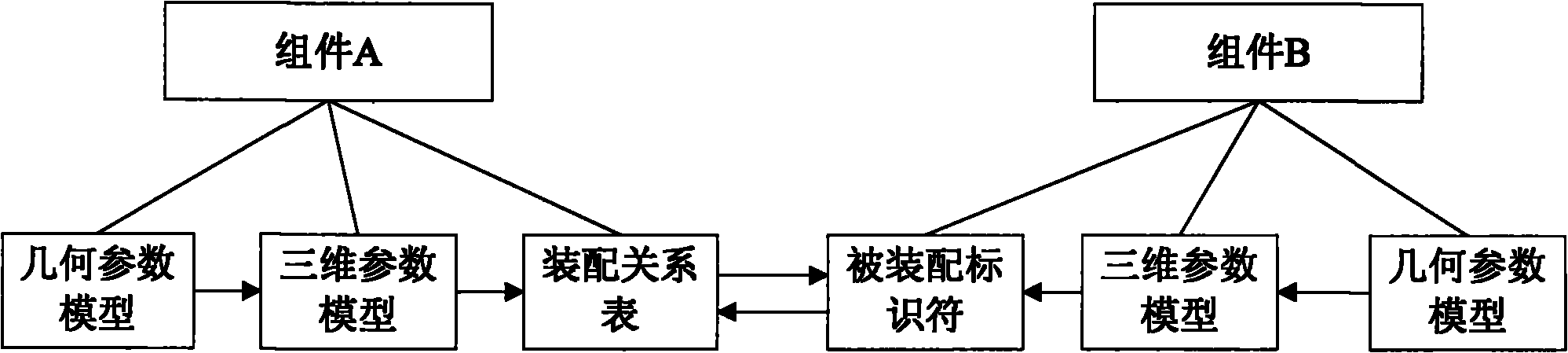

[0048] S11, generating a representation of the component, recording all assembly relationships of the component on the component representation, and the identifier and assembly point of the component as an assembled object;

[0049] In this embodiment, the representation of the component is generated, which is typically a three-dimensional representation, or a two-dimensional representat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com