Electric system of combined copying lathe machine for simultaneously turning and milling internal and external circles of piston ring

A combined machine tool and electrical system technology, applied in the direction of electrical program control, digital control, etc., can solve problems such as unintuitive, low control precision, bulky, etc., achieve good use effect, reduce device cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

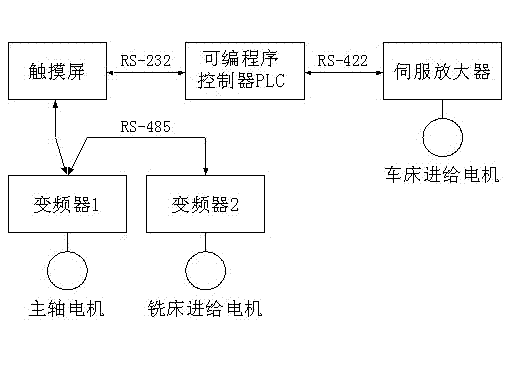

[0012] As shown in the attached figure: an electrical system of a combined turning and milling machine tool for simultaneously profiling the inner and outer circles of piston rings, including a touch screen (embedded integrated industrial computer), PLC, a first frequency converter, a second frequency converter and a servo amplifier, among which the PLC , Inverters and servo amplifiers generally have their own communication protocols, and it is impossible to implement the control requirements that the touch screen and the above components can exchange information by connecting all the devices to a network. Considering that the touch screen can generally provide 2 serial interfaces , so the system takes the touch screen as the center, and makes full use of the two communication interfaces of the PLC to build two communication links: the touch screen co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com