Loading device for high formwork support system full-scale test

A support system and tall formwork technology, applied in the direction of measuring devices, testing of machines/structural components, using stable tension/compression to test the strength of materials, etc., can solve the problems of low construction cost, high construction cost, uneven loading, etc. , to achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

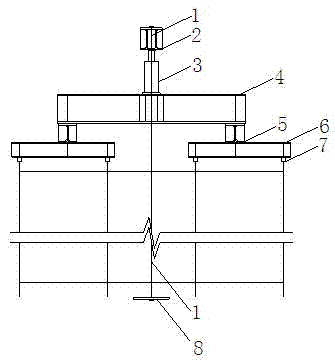

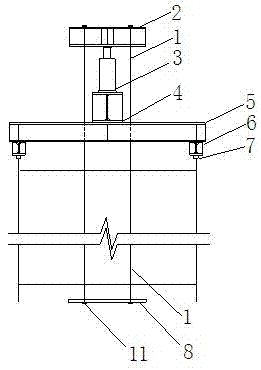

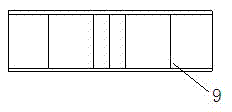

[0019] Refer to Fig. 1. Fig. 1 shows a schematic diagram of a loading device for a full-scale test of a tall formwork support system, including a force-transmitting steel bar 1, a reaction beam 2, a jack 3, a third-level distribution beam 4, a second-level distribution beam 5, a Grade distribution beam 6. The structure of the reaction beam 2 is shown in FIG. 2 , and the structure of the three-stage distribution beam 4 is shown in FIG. 3 .

[0020] The centers of the reaction beam 2, the jack 3, and the three-stage distribution beam 4 are on the same vertical line to ensure that the inaccuracy will not be caused by eccentricity during the loading process. From top to bottom, they are the reaction beam 2, jack 3, The third-level distribution beam 4, the second-level distribution beam 5, and the first-level distribution beam 6, wherein, the length direction of the second-level distribution beam 5 is perpendicular to the length direction of the third-level distribution beam 4, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com