Mechanical amplifier, mechanical amplification system and mechanical amplification method of motion

A mechanical amplifier and mechanical movement technology, applied in mechanical equipment, piezoelectric devices/electrostrictive devices, transmission devices, etc., can solve problems such as low quality, low manufacturing cost, and difficulty in series connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

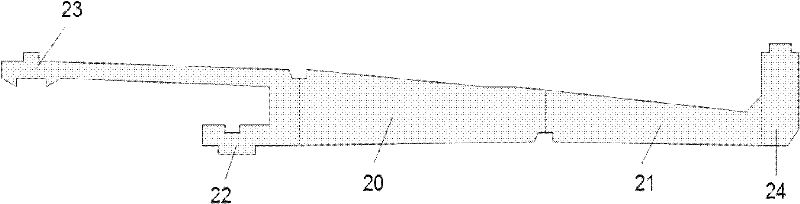

[0038] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0039] An example of a device prepared according to one embodiment of the invention is based on figure 1, represented by the first crossbar 10 . The crossbars 10 and 12 are angled and connected vertically to the base plate 19 in line with the lever. The force F0 keeps the crossbar pressed against the base plate 19 . Via the foil 13 (orthogonal relation to the crossbar), the crossbar is placed in a downward movement d. In this way, the length X1+X2 of the crossbar constitutes a lever with a magnification factor of (X1+X2) / X1.

[0040] The movement 6 of the crossbar 10 is transmitted directly to the crossbar 11 as an upcoming movement. Once reached, the crossbar 11 is pivoted longitudinally about the support element 14 . Due to the angle between the levers, the rotational movement is preferentially absorbed by the first crossba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com