Chained steel tube opening butting device and steel tube butting method

A technology of counterparts and steel pipes, which is applied in construction, building structure, and construction material processing, etc., can solve problems such as low efficiency, achieve convenient use, reduce operation difficulty, and achieve obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

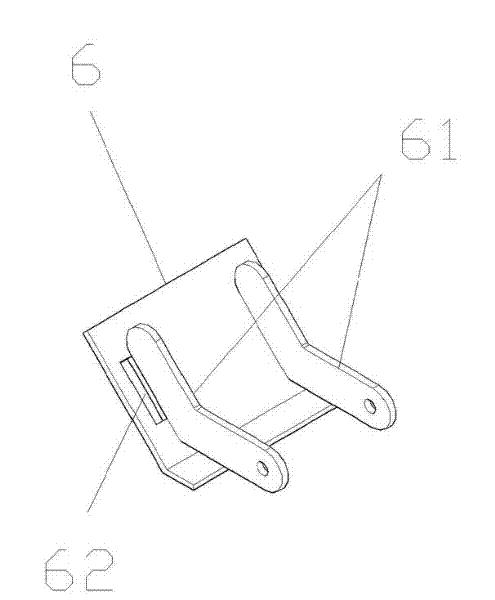

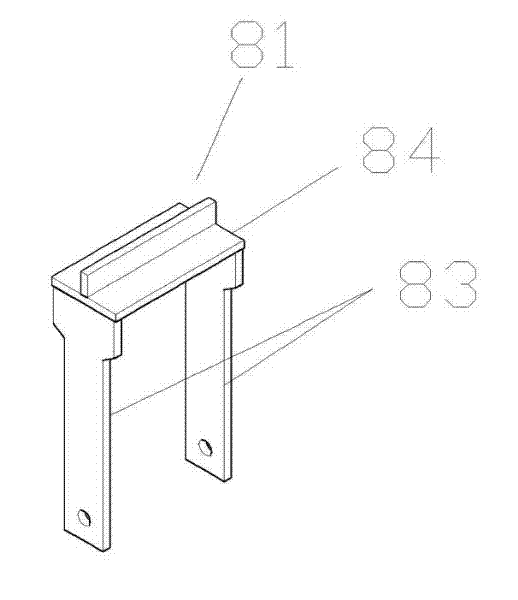

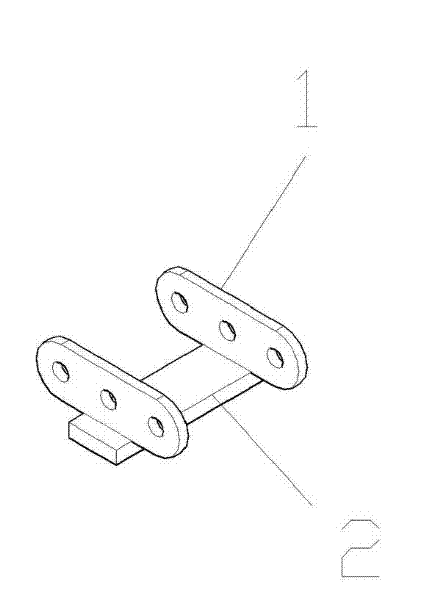

[0038] Such as Figure 1 to Figure 7 As shown, the chain-type steel pipe counterpart among the present invention mainly involves parts including some chain pieces 1, some limit blocks 2, some high-strength bolts 3, adjustment blocks 4, briquetting blocks 5, adjustment plates 6, screw jacks 7, Calibration device 8.

[0039] In this embodiment, it is a chain structure, combining Figure 3 ~ Figure 5 , so a number of chain pieces 1 are sequentially pinned through high-strength bolts 3 to form a chain 9, and the structure of each chain piece 1 is as follows image 3 As shown, there are three perforations on it, the perforations at the two ends are used for fixing high-strength bolts 3, and the perforations in the middle are reserved. The length of the chain 9 is determined according to the actual required size, and the quantity is two in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com