Filling pile coring method and combined concrete coring device

A coring device and cast-in-situ pile technology, which is applied to drilling equipment and methods, sheet pile walls, earthwork drilling and mining, etc., can solve the difficulty of pouring construction steel bars, high storage and maintenance costs, unfavorable small construction sites, etc. problem, to achieve the effect of simple structure, convenient combination and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

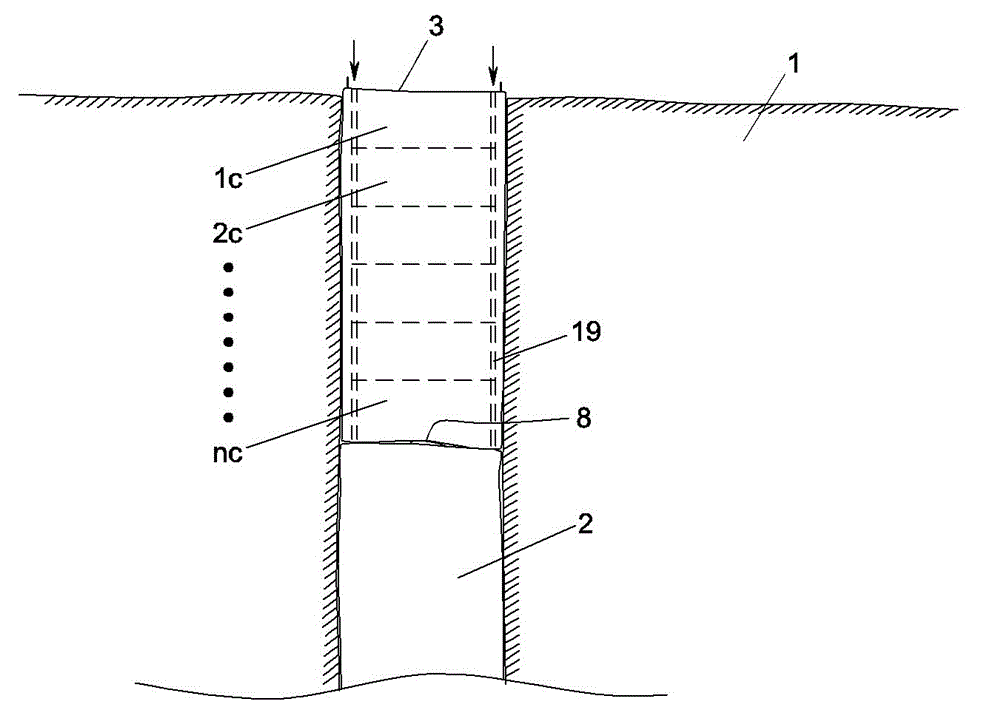

[0027] Embodiment one: see figure 1 The cast-in-place pile is a combination of concrete and circular steel reinforcement layer. The underground pile foundation is formed by drilling a well in the soil layer 1 and pouring concrete. During the pouring and forming process of the concrete cast-in-place pile, some cast-in-place piles may fail to be poured somewhere in the middle Like or form a broken pile, it cannot be used normally. The broken position 8 is judged by echo monitoring, the upper section 3 (broken section) of the broken pile is cored, and the integrated concrete pouring pile is continuously poured on the basis of the lower section 2 .

[0028] This embodiment provides a method for coring cast-in-situ piles. Select a suitable annular drilling tool according to the diameter of the broken pile. For example, for a broken pile with a diameter of D0, the diameter of the annular reinforcement layer is D2. Inside the annular reinforcement layer, use An annular hollow drilli...

Embodiment 2

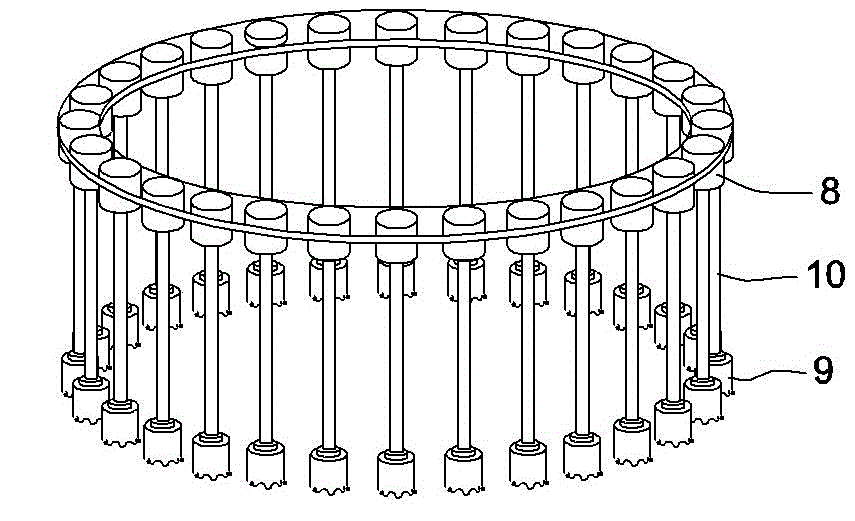

[0032] Embodiment two: see figure 2 and image 3 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is: the annular drilling tool used in the inner side of the annular reinforcement layer 7, the annular drilling tool is evenly distributed with a plurality of independent working drills on the annular surface. The lower end of each drill body has a drill bit respectively, and a series of drill holes are combined to form a circular drill hole. After the inner core 3 is smashed and cleaned, the inner wall of the cylindrical concrete shell 4 forms a rough surface with alternating convex and concave. Number 6 is the broken and protruding rough surface, and number 5 is the concave surface formed by drilling.

Embodiment 3

[0033] Embodiment three: see Figure 4 , Figure 5 and Figure 9 , a combined concrete coring device suitable for the cast-in-situ pile coring method described in Embodiment 2, is that the motor parts of a plurality of drill bodies are sequentially hinged to form a ring-shaped combined drilling tool. Each drill body includes a motor part 8 , a drill rod 9 and a drill bit 10 . Connecting lugs 11 are horizontally fixed on the casing of the motor part of each drill body, and shaft holes 13 are respectively provided on each connecting lug, and the connecting lugs of two adjacent drill bodies are matched and nested together, and pin shafts 12 are installed in the shaft holes. . The drill bodies of the combined drilling tool are fixed to each other. Its fixing method is by a fixed sleeve 16, and near the outer edge of this fixed sleeve, mounting holes 17 are evenly distributed, and the motor part shells of each drill bit are matched and fitted and fixed in each mounting hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com