Method for supplementing lubricating agent to curved steel support seat and curved steel support seat matched with same

A technology for lubricants and steel bearings, which can be used in erecting/assembling bridges, bridge parts, bridge maintenance, etc., and can solve problems such as wear, scrapping, loss of lubricants and wear of bridge bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

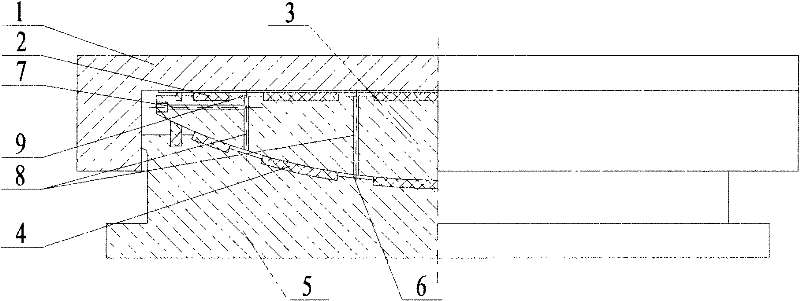

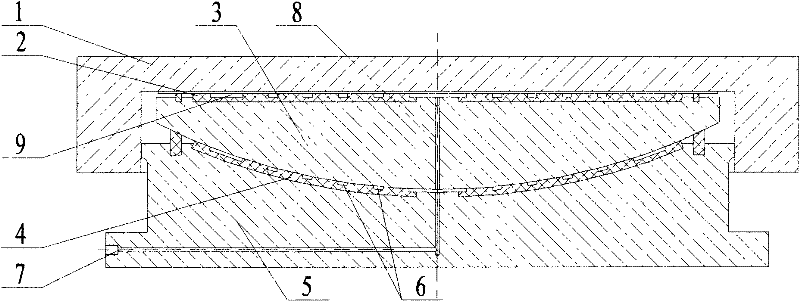

[0020] see figure 2 , a method of replenishing lubricant for curved steel bearings. This method is based on setting a grease storage tank 6 between the liner 3 on the convex curved surface and the sliding plate 4 on the concave curved surface to realize the lubrication of the curved steel bearings. The key lies in: In the structure of the curved steel bearing, a lubricant compensating mechanism connected with the grease storage tank 6 is added, and the lubricant is injected into the curved steel bearing under high pressure from the entrance of the lubricant compensating mechanism, and is filled in the grease storage tank 6. The setting method of the compensation mechanism is: the grease storage tank 6 is connected with each other by means of the diversion mechanism to form a grease storage channel, and the grease injection hole 7 is set on the curved steel support, and the grease storage channel and the grease injection hole 7 are connected by means of the steel tube along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com