Coal bed gas produced water disposal system

A technology for drainage treatment and coalbed methane, which is applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. It can solve problems such as complex water quality, unsuitable for reinjection, and high soil viscosity. Achieve the effect of good treatment effect, simple structure and low operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] The present invention will be further described below in conjunction with accompanying drawing.

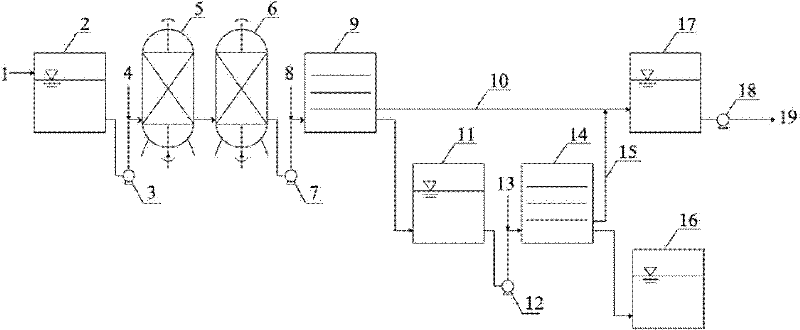

[0029] Such as figure 1 As shown, the present invention is a coalbed methane extraction drainage treatment system, which mainly includes a regulating tank (2), a novel multi-media filter (5), a security filter (6), a reverse osmosis device (9), a primary concentration Water tank (11), concentrated water reverse osmosis device (14), secondary concentrated water tank (16) and reuse water tank (17).

[0030] The working process of the present invention to deal with coalbed methane extraction drainage is:

[0031] After the system starts to operate, the coalbed methane drainage (1) collected in the regulating tank (2) is pumped into the new multimedia filter (5) by the booster pump (3), and the oxidant (4) is added to prevent and control Membrane pollution, the effluent enters the security filter for filtration (6), and is pumped to the reverse osmosis device (9) by the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com