Carrying and storing method of wind tower

A technology for wind towers and tower tubes, which is applied in the field of handling and storage of wind towers, can solve the problems of reducing the utilization rate of the storage yard, affecting production efficiency, and large investment, so as to improve economic benefits and energy saving effects, improve production efficiency, Effect of saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

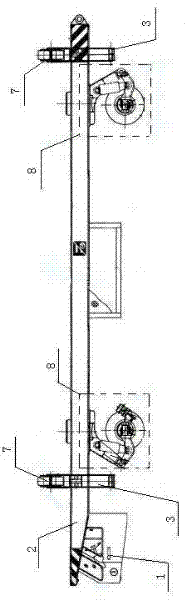

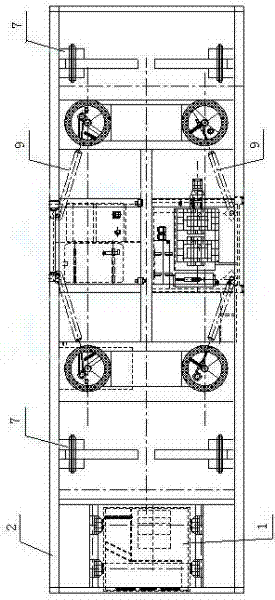

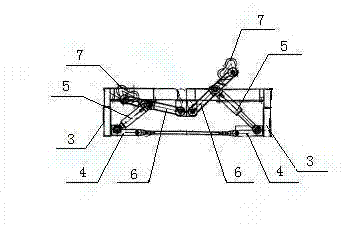

[0021] Such as figure 1 , figure 2 with image 3 A specific embodiment of a method for transporting and storing a wind tower of the present invention is shown, comprising the following steps:

[0022] A. After the spraying of the tower tube of the wind tower is completed, the tower tube is transported out of the workshop through the roller frame, and a flatbed truck is prepared outside the workshop as the load-bearing equipment. According to the length of the tower tube, the flatbed truck is selected for single-car load or parallel load;

[0023] B. Use a crane to lift the tower section to the top of the flatbed truck or move the flatbed truck laterally into the bottom of the tower tube, that is, into the roller frame;

[0024] C. Through the program control center in the cab of the flatbed truck, the movable roller support mechanism connected by the two column groups placed left and right under the frame of the flatbed truck is controlled, that is, each column group inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com