Correction method and correction apparatus for laser marking and laser marking system

A laser marking and calibration method technology, applied in the optical field, can solve the problems of low accuracy, the calibration accuracy cannot meet the high-precision requirements, and can not meet the industry requirements, and achieves the effect of high calibration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

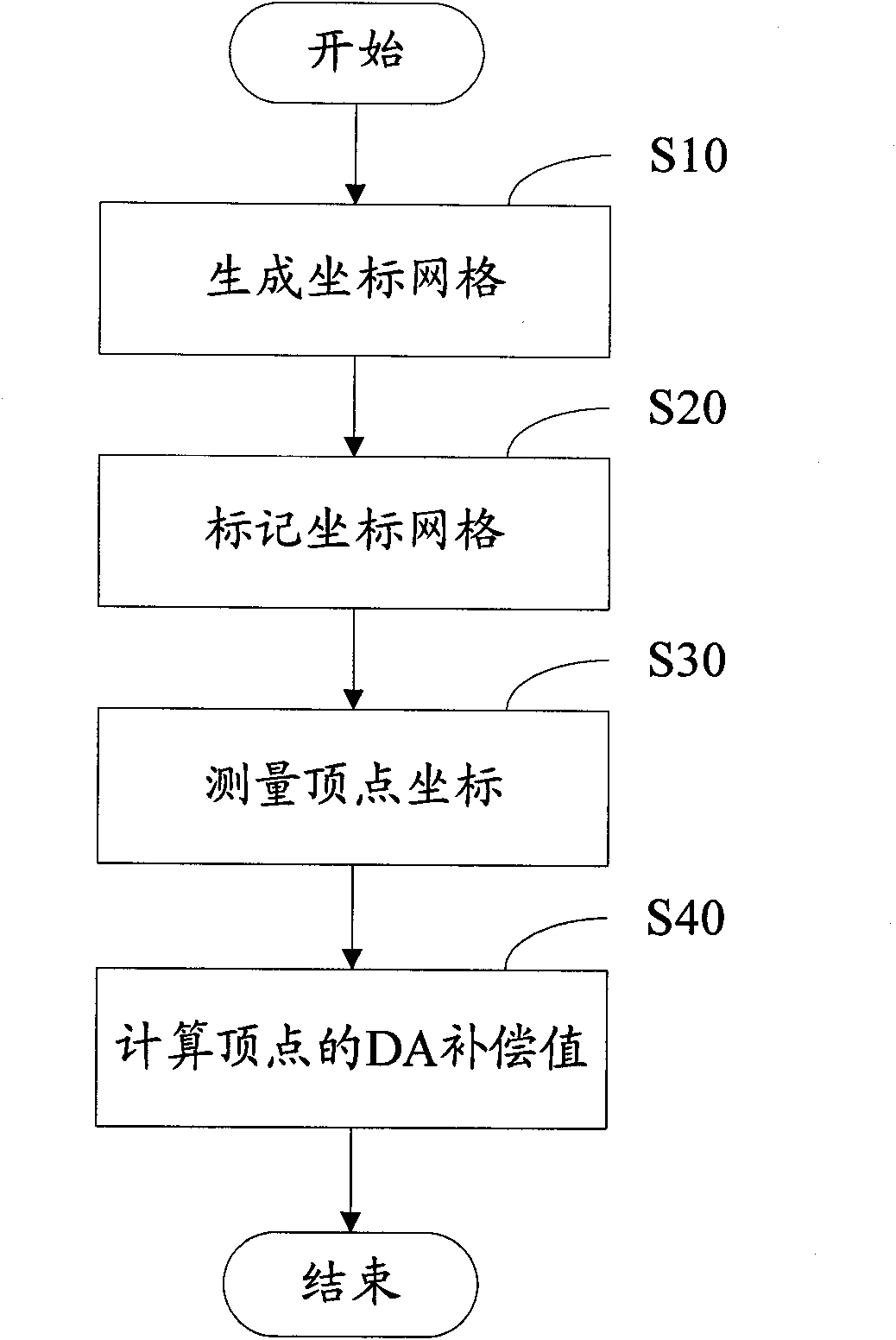

[0041] The correction method for laser marking of the present invention firstly needs to obtain error data. Such as figure 2 As shown, in a preferred embodiment, the error data can be obtained through the following steps:

[0042] S10, generating a coordinate grid.

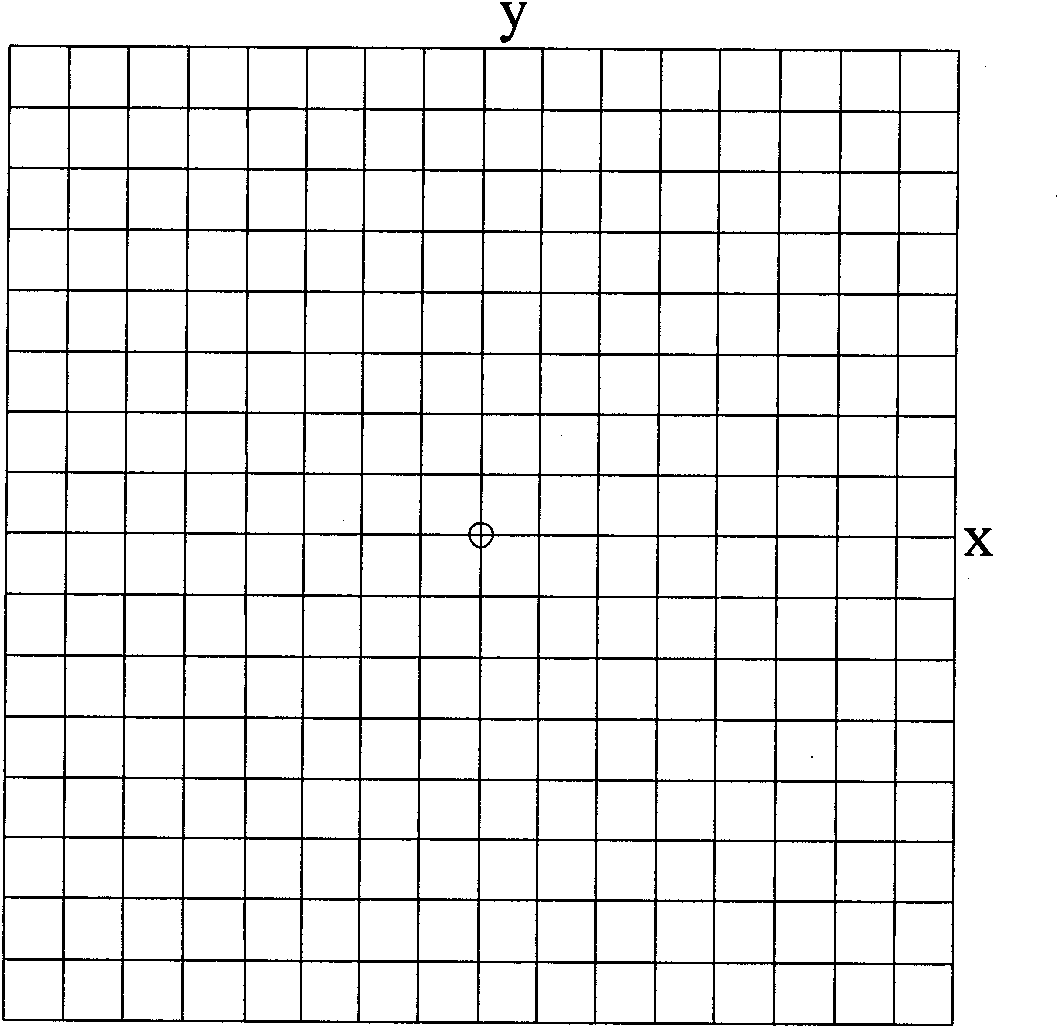

[0043] Divide the area to be marked (such as a 100mm*100mm square) into 2 k line 2 k Column grid coordinate grid (k is a positive integer), the size of k can be selected according to the calibration accuracy, the larger k is, the higher the calibration accuracy is, but at the same time, the time required for calibration will increase geometrically. In a preferred embodiment, N is 16, 32 or 64 (ie k=4, 5, 6), image 3 It is a grid diagram of grid coordinates when N=16 in one embodiment.

[0044] S20, mark the coordinate grid.

[0045] Use the laser marking system to be calibrated to mark the grid map of the grid coordinates on the horizontal calibration plate.

[0046] S30, measure the coordinates of the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com