Leaf wetting method for improving quality of redried tobacco sheets

A technology for moisturizing leaves and quality, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems such as the quality and application value of raw tobacco cannot be fully reflected, the moisture distribution on the surface of tobacco leaves is uneven, and the industrial availability of finished tobacco sheets is reduced, etc. Achieving good application prospects, bright and uniform tobacco leaves, and improved sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

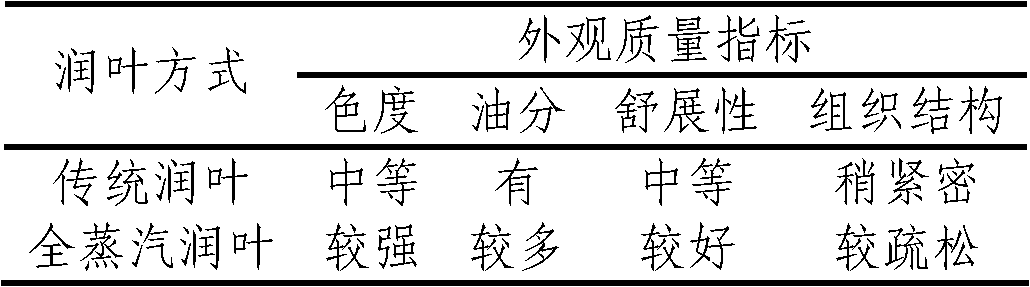

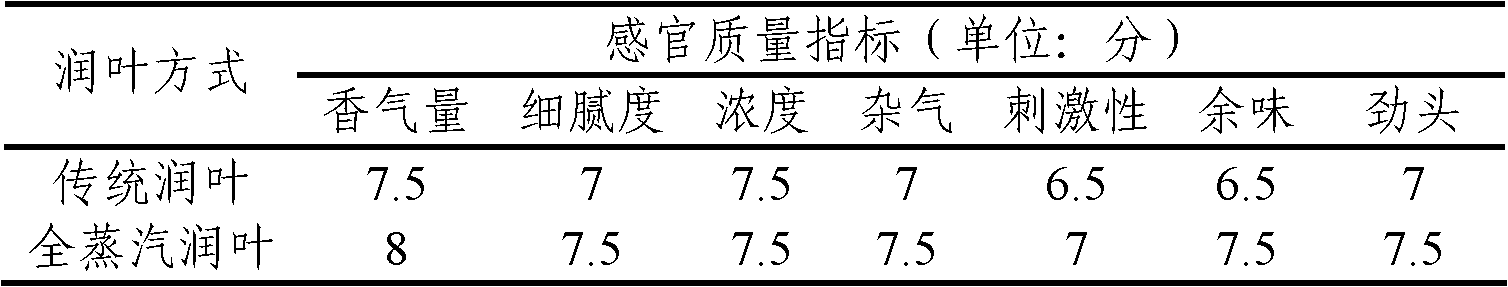

[0015] For the 2009 Yunnan Baoshan K326B3F tobacco leaves, the leaves were moistened by traditional technology and full steam, as follows:

[0016] Traditional process of leaf moistening: According to the medium tobacco leaf processing parameters stipulated in YC / T146-2001, the leaves are moistened by mixing soda and water.

[0017] Full steam leaf moistening: set the steam pressure to 0.8~1MPa; turn on the heat exchanger before feeding, preheat the leaf moistening cylinder to make the circulating hot air reach above 90°C, during the preheating process, it is forbidden to add steam into the leaf moistening cylinder , to prevent condensation and reduce the appearance of water stains. Yirun: Feed K326B3F tobacco leaves 20×10 3 kg, set the flow rate of incoming tobacco leaves to 11×10 3 kg, open the hot and wet steam valve to make the steam pressure reach 0.95-1MPa, increase the temperature and moisture content of the first-run tobacco leaves, so that the temperature reaches 56...

Embodiment 2

[0027] For the 2009 Lufu Xunhong Da C3F tobacco leaves, the leaves were moistened using traditional leaf conditioning techniques and full steam, as follows:

[0028] Traditional process of leaf moistening: according to the processing parameters of fine tobacco leaves stipulated in YC / T146-2001, the leaves are moistened by mixing soda and water.

[0029] Full-steam moistening: open the hot and humid steam valve to make the steam pressure reach 0.85-95MPa, increase the temperature and moisture content of the first moistening tobacco leaves, so that the temperature reaches 52-56°C and the moisture reaches 18%-20%; second moistening: According to the technical parameters specified in YC / T146-2001, open the front / rear steam valve, adjust the temperature of the second moistening to 52-56°C, and the moisture to 18%-19%. Control the circulating hot air in the range of 80-100°C to facilitate the further uniform infiltration of water. After 11 minutes, finish moistening the leaves.

...

Embodiment 3

[0039] Repeat Example 1, the 2009 Baoshan K326X3F tobacco leaves were moistened by traditional leaf moistening process and full steam respectively, wherein the full steam moistened leaves had the following differences: open the hot and wet steam valves to make the steam pressure reach 0.95~1MPa, increase The temperature and moisture content of the tobacco leaves are such that the temperature of the first-run tobacco leaves reaches 52-56°C, and the moisture reaches 18.5%-19.5%. The second moistening temperature is 56-62°C, and the moisture content is 19%-20%.

[0040] The evaluation of the quality of the red-roasted slices shows that compared with the traditional leaf moistening, the water-stained smoke in the 2009 Baoshan K326X3F finished tobacco slices after full-steam moistening and threshing and redrying is significantly reduced, and the rate of large and medium slices is increased by 1.23% %, the loss rate of large and medium slices before and after rebaking decreased by 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com